|

Re: Various CL Pickings

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Posted on: 2020/1/26 8:44

|

|||

|

||||

|

Re: Lower radiator hose collapse

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

https://www.summitracing.com/parts/hed-29012

You will need to have the ends rolled or create barbs with weld to keep the hose sections from slipping. Mandrel bends are constant diameter.

Posted on: 2019/12/24 13:54

|

|||

|

||||

|

Re: How bad do my pistons look?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

In the photo of cyl #2 (marked in red) , a small piece of the piston is missing, or burned away. With the exception of cyl #5, all are using oil. The pitting in the cylinders is the result of long term storage without lubricating (aka pickling). When rust forms in the bore, and the engine is rotated, the rings will scrape the oxidation loose , where it will lodge between the piston ring and the ring land. When the piston changes direction, it rocks. The particles that have accumulated will cause the ring to stick, resulting in lost cylinder sealing. The 2nd ring's primary function is oil control. If the cylinder is worn,or out of round, the ring cannot seal and the engine will use oil. Oil in the cylinder will cause detonation. Detonation burns pistons, breaks rings etc.

Assuming that your engine has mechanical tappets, roll the engine over and measure valve lash. Measure the intake lash when the exhaust valve starts to open, and the exhaust lash when the intake valve starts to close. Record the results. Examine the valve springs, observe the motion of the valve. While the valve is open, look for cracks in the seat area. Good luck.

Posted on: 2019/12/18 21:41

|

|||

|

||||

|

Re: 1937 115C mechanical refresh

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

return line to crankcase

Posted on: 2019/11/30 18:44

|

|||

|

||||

|

Re: 1937 115C mechanical refresh

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

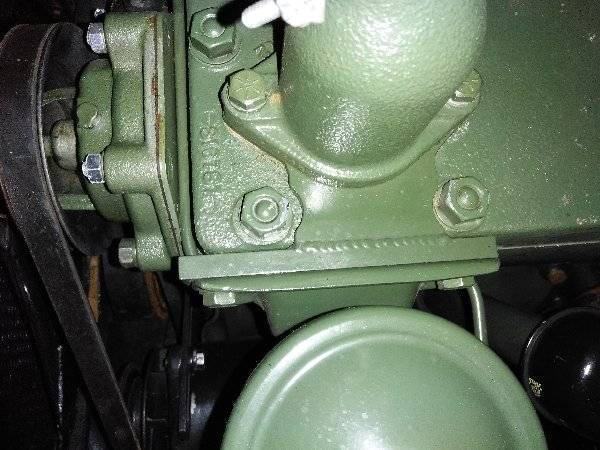

filter bracket

Posted on: 2019/11/30 18:42

|

|||

|

||||

|

Re: 1937 115C mechanical refresh

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

behind water pump

Posted on: 2019/11/30 18:40

|

|||

|

||||

|

Re: 1937 115C mechanical refresh

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

right front oil line

Posted on: 2019/11/30 18:39

|

|||

|

||||

|

Re: 1937 115C mechanical refresh

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

The 1937 block has no oil ports on the left side or tapped holes on the cylinder head to mount a filter.

I attached a line to the front main galley on the right side of the block,and routed it up and behind the water pump, then along the head to the inlet side of a aftermarket filter housing. I drilled and tapped a hole in the block behind the generator and attached a tube to the discharge side of the filter housing. The filter housing uses a .060" hole in the center tube as the restriction. I fabricated a bracket that mounts between the water outlet and the head to mount the filter housing. I didn't like the idea of boring the original connecting rods to the later bearing od. This process will expose the rod bolt at the parting line. Instead I used Clevite #988P std. These fit various Nissan models from 1968-1989. Standard size Nissan rod journal is the same size as Packard .010" undersize. I set bearing clearance at .002 mains, and .0018 rods. Oil pressure is 40# hot using 5w-30 oil. It requires cutting the lug notches in the rod and cap, and drilling the pin oil hole and spit hole in the bearing. I'll post pictures of the oil system.

Posted on: 2019/11/30 18:19

|

|||

|

||||

|

1941 160

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

1941 160 Sedan on proxibid

https://www.proxibid.com/Collector-Cars/1941-Packard-160-Sedan/lotInformation/49858915

Posted on: 2019/9/4 18:30

|

|||

|

||||

(201.17 KB)

(201.17 KB)