|

Re: 1947 356 engine

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think the item on your first photo is a check valve and if I am correct, from the second photo I think it is an improper installation of a drain which was added in 48 and was retrofittable to earlier 356 engines. The drain would have a check valve assembly on the end of the tube which closes as soon as vacuum is present but will open when the engine is stopped so any condensed fuel sitting in the bottom of the intake manifold can drain out. That item is detailed on page 36 in a service counselor article. In that photo the check valve looks a bit different in shape than what I think is what you have in your first photo.

On a Clipper thru 47 the wipers were electric so no dual action fuel pump. The usual vacuum routing is not present so on the top of the intake manifold toward the rear is a plugged port which is available if needed for vacuum accessories such as the vacuum antenna or windshield washer. In the middle in the square manifold section under the carb is a larger plugged port used if the car has the Electromatic clutch. I think someone used that port for the drain which means the drain would not work as intended. On 356 engines used in models with vacuum wipers a port on the front top similar to the one at the rear went to the fuel pump vacuum section and then on to the wipers and accessories. The middle port still went to the Electromatic but some models also had the vacuum to the fuel pump originate there instead of at the front top port.

Posted on: 4/20 11:32

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just my

When I replaced my fuzzies that used clips I taped and wedged the strip in place then used a sharp pointed 90 degree scribing tool to push in thru the existing door holes from the inside and mark the locations in the rubber on back of the strip. If you don't want to do that or if your fuzzies are the type held with staples then as long as the back of the strip is somewhat smooth and there are no large gaps I think they could be glued by using a good strength heavy adhesive. That alone may be enough but with the force of the window and particularly the chrome frame surround pushing and pulling against it I would also think a bit of mechanical strength would be a good idea. Using a clip at each end and maybe one in the middle would add a bit of security. Of course as HPH mentioned, the downside to adhesive is they will be difficult to remove again.

Posted on: 4/15 20:05

|

|||

|

Howard

|

||||

|

||||

|

Re: Don’s 1937 (120) 138CD Deluxe Touring Limo

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Not familiar with prewars so can't say but wouldn't be surprised if it is an assembly. Clippers and some other years had a welded or stamped one piece unit.

Posted on: 4/13 23:43

|

|||

|

Howard

|

||||

|

||||

|

Re: Firing order

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

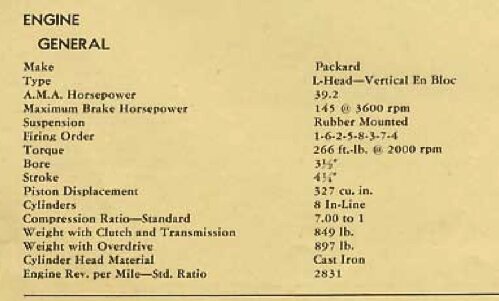

Here is the 48 Super Eight engine specs from Service Counselor Vol21 #11 dated June 15, 47. All planned mechanical specs for the vehicle as introduced are found in that issue which can be downloaded from the literature archive. A later issue, Vol21 #19 also has specifications which could reflect any changes to pre introduction specs.

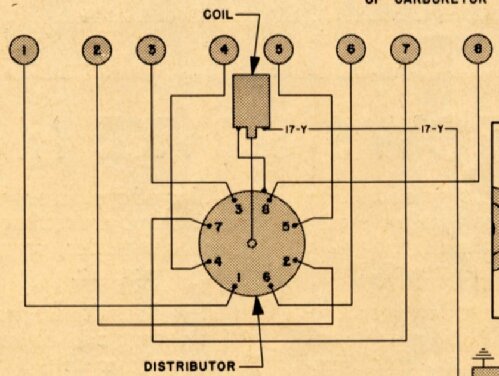

A 48 wiring diagram can be found in the literature archive too but here is an excerpt showing the distributor cap and approximately where # 1 plug wire would be if the distributor is installed per spec. Distributor rotates counter-clockwise.

Posted on: 4/13 19:52

|

|||

|

Howard

|

||||

|

||||

|

Re: 1937 120 Conv. Sedan - Blanche

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

I don’t know that I agree that Packard only used valves with handles. You are correct. I should not have said that as an absolute fact. I will say I have not seen the type with a bolt as shown in the photo in common use but agree dealers could have installed any number of variations. Very possibly there are more like yours and the photo and even some different still. Have even seen some with round knobs instead of the straight bar.

Posted on: 4/13 19:42

|

|||

|

Howard

|

||||

|

||||

|

Re: 1937 120 Conv. Sedan - Blanche

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You might verify with Napa if this BK 6601418 item has the correct specs. Napa did not have this listing when I bought my valve several years ago. Specs says 3/8 with 5/8 hose and it does have an angled outlet.

Posted on: 4/13 19:12

|

|||

|

Howard

|

||||

|

||||

|

Re: 1948 Packard Master Sales Program

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You might send a PM to Mathew Rattray in Australia and see what he uses as a player. He has made several of the YouTube items. Not sure how often he gets on the forum anymore to pick up a PM but if he doesn't respond reasonably fast maybe you could also ask if Mal (Ozstatman) or one of the other Australian members could get him a message. I know some of the old talking or instructional records of the time used a speed of around 16 rpm which many of the record players made in the 50s could do.

Posted on: 4/13 18:57

|

|||

|

Howard

|

||||

|

||||

|

Re: Light Bulb Designation, Vendors that Sell

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

My comments about how the extra rear bulb is needed are strictly referring to how the factory chose to do the original turn signal option. You specified the "proper switch" and I agree. If you want to get an aftermarket turn signal setup absolutely the same bulb can be used and many people made add on turn signal switches starting in the 40s and still do. Some of them even had a mechanical cancelling function like yours using the roller against the wheel to operate a mechanism inside the enclosure similar to the factory original setup but most did not. A couple of units made today look a bit like the older switches but both then and now all the aftermarket setups needed different wiring than stock. To use the same bulb requires modifications to the original circuit to be made and there doesn't seem to be a standard circuit with the same colors working for all. Once the aftermarket setups are installed, unless their wiring diagrams are still available to see what was done trying to use the original factory wiring diagrams in tracing a problem will be of little use.

Posted on: 4/13 18:39

|

|||

|

Howard

|

||||

|

||||

|

Re: 1937 120 Conv. Sedan - Blanche

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The heater shutoff valves Packard used over the years seemed to all have a twist handle to turn it off. Wonder if the original valve somehow got damaged. Perhaps someone tried to adapt something else or the bolt was used to plug or repair the broken valve. If you cannot get it to turn and shut the flow off new universal shutoff valves can be found at many parts stores. They don't have the angled outlet to raise the hose higher over the manifold though. The threaded end for port in head is 3/8 NPT and outlet would be for 5/8 hose. If you want to replace the valve you could also get a 3/8 male to 3/8 female adapter fitting to raise the valve another inch and better get hose above the manifold.

Attach file:  valve.jpg (99.29 KB) valve.jpg (99.29 KB)

Posted on: 4/13 17:57

|

|||

|

Howard

|

||||

|

||||