|

Re: Ultrasonic Cleaner Rust removal

|

||||

|---|---|---|---|---|

|

Home away from home

|

I’m sure we all have a cache of red stuff to get rid of, so thanks for starting this thread. I’m currently a fan of Evapo-Rust purely for the simplicity of use, but it takes quite a while to finish the job. Perhaps those that use an electrolysis process can fill-in some details on that method.

I do had a question about the ZipLoc bag technique, “Is the top of the bag sealed and also held above the normal cleaning fluid level, or once sealed the top of the bag is allowed to go wherever it wants to go?” Kevin’s comment suggests the top of the sealed plastic bag is held above the waterline. dp

Posted on: 2021/1/21 22:26

|

|||

|

||||

|

Re: '38 1608 V12 Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

So far I've used mine for only cleaning carburetors. Simple Green and water was used per the instructions that came with the unit. I kept cleaning and cleaning until the cleaner would run for one hour without darkening the solution. I must say the first few times the solution will darken in less than 10 minutes . . . and maybe 'darken' is a bit too polite, because the first time the solution was more black than just darkened. I normally use a solution temperature on the high side, and cleaned the 'crud' off the outside of the carburetor with lacquer thinner before it went into the drink. My goal was to let the US cleaner do its thing on the passages that would be otherwise inaccessible, and not have to clean the easy to remove the 'crud' on the outside. On the internet there are parts baskets that look like small spheres made of stainless screening. The spheres open to allow the adding the small parts, and then lock closed. All you have to do is to throw the basket into the cleaner, and the parts don't disappear.

If anyone has used an ultrasonic cleaner with Evapo-Rust let us know the results. dp

Posted on: 2021/1/6 18:13

|

|||

|

||||

|

Re: Vintage Packards on the Street Thread...

|

||||

|---|---|---|---|---|

|

Home away from home

|

With respect to the '55 - '56 Ford comment . . . from the front the easiest way to tell would be, round turn signal lens = 1955, rectangular turn signal lens = 1956.

Posted on: 2020/12/29 22:54

|

|||

|

||||

|

Re: KPack's 1954 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

Kevin, that's a difficult question to answer. I noticed in the 'Coming together' photo the same gasket seems to be 'hanging-out' over its entire outer edge as you said. Perhaps it's nothing more that the manufacturer of the kit made the decision to have a gasket that would be more robust if it shifted a bit. Not only would there still be gasket material available to seal, but a wider gasket would be less likely to shift in the first place. There is no harm with the gasket 'hanging-out' on the outside of the carburetor. If it somehow degrades and starts falling apart no ill effects would arise. So let's talk about the '20201208_071831.jpg' photo . . . that gasket appears to be in the engine's inlet air stream, and as such if degradation occurs a benign situation may not be guaranteed. When I first saw this photo I went out to the garage and unpacked my spare WDO, which is not the same design as yours, but it is a Carter two barrel produced only a few years before. In that carburetor the gasket is not visible, it does not protrude into the air stream. Since my experience with WGD is limited I would ask those with that experience to weigh-in on whether it's normal for the gasket to protrude into the air stream . . . I know the answer for the WDO.

dp

Posted on: 2020/12/17 22:22

|

|||

|

||||

|

Re: KPack's 1954 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

Kevin, in your posting #454 the photo looking straight into the throat of the carb I see quite a bit of air horn gasket. It looks different than what I was expecting. I know getting the vacumeter piston and link to play well with the gasket can be a challenge.

dp

Posted on: 2020/12/16 22:21

|

|||

|

||||

|

Re: KPack's 1954 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

Seems that Kevin's carburetor is also missing the fast idle link, the choke trip lever (that's the part in Tinman's photo), and the choke piston link. If the fast idle link is AWOL then the choke connector rod is also likely missing. The link and rod should have been visible in Kevin's 'Finished rebuild 2' photo in post 456, but they are missing.

It looks that what the carburetor was configured with a manual choke a lot of Carter's automatic choke hardware was removed. My immediate concern is the loss of the high idle feature. There may be climate conditions where the engine will start but either immediately stall, or run really rich because the throttle is not reset to high idle during warm-up. Kevin can ultimately determine when unloading is necessary, so in my mind that Carter hardware is optional. I've attached a file containing the US Patent 2,402,361 (see Tinman's photo). The operation of the automatic choke, fast idle, and vacuum/air flow/full throttle unloading are discussed in the disclosure. dp

Posted on: 2020/12/16 14:05

|

|||

|

||||

|

Re: KPack's 1954 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

Kevin, a few items about the carburetor:

1. The means to adjust the float level is quite different when installing a 'Daytona' type fuel inlet valve. With this valve the float level is adjusted by adjusting the number of gaskets between the housing casting and the female portion of the valve. With the tapered valve a tab on the float is bent to achieve the correct float level. When using a 'Daytona' valve the aforementioned tab should press pretty much in the center of the valve . . . that's important! 2. I use a twist drill as a float level gauge. At times I've also measured the gasket thickness and correct the recommended dimension so I can check the level with the gasket in place. 3. Air flow through the automatic choke. There is a drilled passage in the housing that 'tunes' the vacuum applied the vacuum choke un-loader piston, and ultimately limits the total flow. I think the labyrinth seal geometry on the piston actually sets the total flow. If your choke set-up does not have the piston installed you will probably be on the high side of air flow and be limited by the orifice. If the choke does not have the unloader piston I think I would put a cap on the choke stove fitting. If the unloader piston is still installed it doesn't matter if the stove tubing is installed, or not, but the unloader function will not work if the fitting is capped. Surely the temperature will change whether the stove is hooked-up or not, but not the total amount of air entering the choke housing. I think the thread where the choke stove tubing attaches is a simple ? inch tubing compression fitting. Your local hardware store should have all of the parts you need, including a cap. If it was mine, I would put a cap on the fitting when the manual choke hardware is installed and manage the unloading myself. I have an air horn/choke housing for a WDO that appears to have over-temperature damage, in that the two screws (yours has three ?) that hold the adjustment cover on are no longer parallel . . . they are bent outward. Unless quite warm carburetor castings are not known for their ductility, hence the conclusion that high temperature was part of the scenario. War story: When my dad was teaching me how to start his '48 Chevy with a manual choke and throttle, his advice was; Choke full closed, throttle half, key on, depress started pedal, when engine fires push choke in to 'one finger' unless it was really cold and then it would be 'two fingers', finally adjust throttle to keep engine running, but all of that was done in less than a second, so the engine didn't over rev. I still use that process on my Brand X, which is by far the best starting of my 'old cars'. The Zenith carburetor on Brand X is an up-draft, so there is no accelerator pump. I've convinced myself if the choke and throttle is set correctly where is no need to 'pump the gas' more than what is necessity to set the automatic choke. I'm done. dp

Posted on: 2020/12/9 13:59

|

|||

|

||||

|

Re: KPack's 1954 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

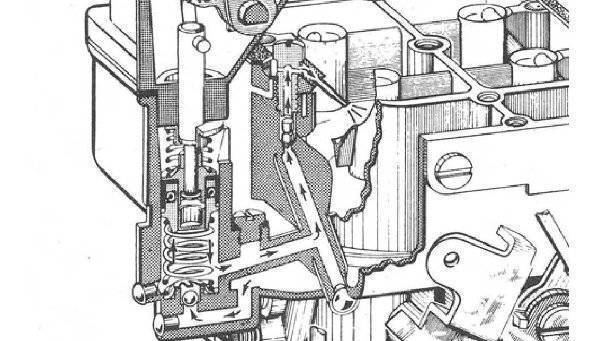

Kevin; I downloaded one of the WDG data sheets available on this site, and I would say the pointed needle looks like the accelerator pump discharge check valve, "pump check needle' in Carter speak. See part 17-70 on the 728S/SA sheet. It would be installed pointed end down. The attached drawing is for a WCFB, but the concept is the same. When you depress the throttle pedal the accelerator pump begins to push fuel out of the pump chamber . . . the bottom ball check will close, and the upper needle is pushed upward by the flow of fuel. When the accelerator pump has finished the discharge stroke the needle will fall back to its seat by gravity. When you let off the gas the pump rises and the bottom ball opens. The needle, already being on its seat, inhibits air from flowing backwards into the discharge nozzles. Early Carter documentation might show a 'ball check' in the upper position. I think the needle design was introduced in Packard carburetors in 1941. That's the first part that falls out the first time the carburetor is tipped upside down. If all the fact were known, I've completely assembled a carburetor only to have one part left over . . . yep it was the 'little pointed thing'! The accelerator pump won't work well if either check valve is missing or malfunctioning.

The needle in the fuel inlet valve will normally have an undercut where a spring wire clips on and loosely attaches the needle of the float. See part 25-165S on the same sheet. Bye the way, I've taken a few photos and measurements of the 'ropes' that fit in the trunk between the fender and wheel tub. I think that subject was discussed a while back. If you still need that info I'll post the information. dp

Posted on: 2020/12/7 23:15

|

|||

|

||||

|

Re: Various CL Pickings

|

||||

|---|---|---|---|---|

|

Home away from home

|

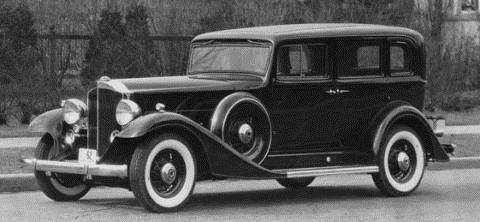

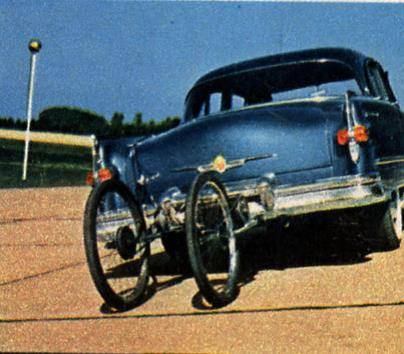

PackardDon - I've got a '54 Cavalier out in the garage with the same trunk mounted script in the same location. If it's wrong then the population just doubled. On the last page of the '54 Packard and Clipper sales brochure there's a photo of a dark blue Cavalier on the test track with two fifth wheels attached. It looks like the same script is on that car. Now the question is whether a car can have two fifth wheels?

dp Attach file:  (26.26 KB) (26.26 KB)

Posted on: 2020/12/4 22:45

|

|||

|

||||