|

Re: T/L Brake light switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Nothing needs to be done to the switch as to bleeding it. Pressure in place does it all. Old and even NOS switches seem to be hit or miss. One thing is make sure the pedal is retracting all the way so there is no chance the compensator valve is staying closed. If the switch is active, pull back on the brake pedal and see if it goes out. If it does there is something binding the pedal that needs to be found. If no change then a bad switch.

Rather than get another 3 pin switch, I would get one of the replacement kits from Dwight Heinmulller or the Pacific Northwest region or maybe even one of the vendors. That kit uses an ordinary easily found and inexpensive 2 prong switch and adds a relay to do the TL switch function. Original wiring plugs right in. Several of us have gone one farther and completely replaced the hydraulic switch. We have mounted a mechanical switch to the steering column inside the car which is operated directly by the pedal arm. A short extension loom goes out and connects to the original plug.

Posted on: 2017/3/19 14:34

|

|||

|

Howard

|

||||

|

||||

|

Re: T/L Brake light switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

These switches are now as much as 60 years old, there might have been a run of service replacements a short while later, so they are all at least 50 years old. Are you running silicone fluid? (Dot 5) that is known to eat the old stock switches in short order.

You can use a brand new regular two-prong switch available from NAPA in conjunction with a simple relay to do what the OE three-prong switch does. All of that is buired under the battery tray, so someone would have to look hard to find it .

Posted on: 2017/3/19 14:39

|

|||

|

||||

|

Re: T/L Brake light switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I have not experienced early failure of the OEM-type switch in my own car which uses DOT-4 brake fluid, the unit in the car now has been there for 20+ years. But I've frequently heard of early failures when using DOT-5. IMO the simplist and most inexpensive solution when you experience switch failure and don't have an OEM type replacement or are using DOT-5 fluid is to go to the conventional switch and relay system that Mr. Pushbutton has mentioned in his post just above. It's available very inexpensively as a neat little kit as shown below, the hydraulic switch is a NAPA SL-134 (United 7715) or equivalent, and is included in the kit. This is the same switch used in almost all Packards with hydraulic brakes from 1954 and back.

Posted on: 2017/3/19 15:08

|

|||

|

||||

|

Re: T/L Brake light switch

|

||||

|---|---|---|---|---|

|

Home away from home

|

I did like Howard, I put in a mechanical switch on the steering shaft and had it activate a relay to turn on the brake lights. It's been working for over 16 years and over 60,000 miles. It's on my 55 Clipper.

I had the left front wheel axle nut too tight and it made heat that traveled up and would melt my hydraulic brake switch. After backing off the wheel axle nut, I went ahead and put in the mechanical switch. The load levelers work just fine with the relay and mechanical switch. The switch is a normally closed switch and the brake pedal rests on it so the switch is off (open) and so is the relay so the load levelers work. When I push on the brake, the brake pedal arm releases the switch (closed switch), so now it turns on, and the relay turns on and turns on my bright brake lights. When I release the brake pedal the switch is compressed and the relay is turned off (and so is the brake lights) and the load levelers can start working. You can't see the switch and relay because they are under the dashboard. My 2nd Clipper is working fine so I won't put this change on it, only if I need to.

Posted on: 2017/3/19 15:40

|

|||

|

1955 Clipper Custom

1940 160 Touring Sedan 1953 Patrician 1948 Super 8 Limo |

||||

|

||||

|

Re: T/L Brake light switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

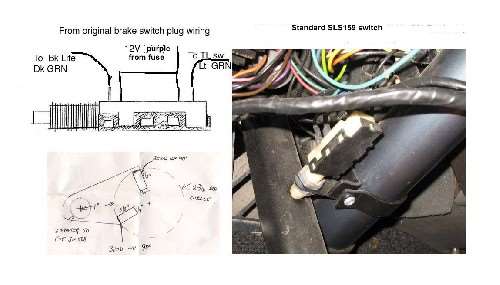

I tried replacing the brake-light switch normally, but DOT5 ruined it quickly. I replaced it with a standard GM switch that originally lights the brake lights and turns off the cruise control.

I bolted it to the bottom of the steering column and hooked up the cruise portion to the TL controls. I have had this installed in my 400 since the mid-90s and am going to install it in my Caribbean as well. It costs somewhere around $10.00 and you have to make up your own wiring.

Posted on: 2017/3/19 22:29

|

|||

|

||||

|

Re: T/L Brake light switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Assuming it is for a 56 here is a a photo and bracket that would work for the switch Randy shows and probably the one mentioned by duane.g. I used a different switch but all have the same principle. The pedal arm depresses the switch plunger when brakes are relaxed. The bracket is simple to make and holds onto the column with a heat shrink covered hose clamp holding the two bent up tabs to the column.

The 1" dimension between column and switch hole may not work for a 55 because of the different pedal arrangement so that dimension would need to be verified on 55s

Posted on: 2017/3/19 23:06

|

|||

|

Howard

|

||||

|

||||

(74.78 KB)

(74.78 KB)