|

Re: piston ring size

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

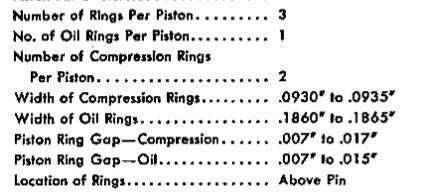

I wonder if you have replacement or aftermarket pistons. The numbers you give are larger than the specs given in the service manual and service coordinators for the 51 engines as shown below.

Some minor variations over the years but except for the 54 359 engine where the rings are narrower and slightly different spec top and bottom, the given specs are essentially the same 51-4. They did make a change to or maybe an option of chrome plated rings in mid 51 but no mention of any width changes. Attach file:  (22.40 KB) (22.40 KB)

Posted on: 2013/3/15 23:15

|

|||

|

Howard

|

||||

|

||||

|

Re: piston ring size

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

HH,

Thank you for the information, however, what is in the manual is actually the piston ring thickness (note that the oil ring is twice as thick as the compression rings). My replacement rings are the same thickness. What I request is the horizontal distance from front of the ring to the back of the ring that fits into the piston groove. The replacement rings I got are .015 wider than the originals. I can't tell if the supplier gave me the wrong rings or the car I own has some kind of after market pistons that were installed before I bought it. I took the pistons out three times already, when I take it apart for the fourth time I need to know if I can just replace the rings or have to put in new pistons and rings. Thanks in advance

Posted on: 2013/3/16 13:23

|

|||

|

||||

|

Re: piston ring size

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I see what you're looking for -- I don't recall seeing that dimension as a spec Packard ever mentioned.

The current Perfect Circle (now called Mahle pistons) term is radial thickness. Their performance catalog mentions it in specs for their part number rings but the regular aftermarket catalog just lists the bore and width. Of course, Packard is not mentioned in either. Perhaps someone with an old Perfect Circle catalog might be able to supply it. The formula given for calculating the standard radial or "D" wall thickness is bore diameter divided by 22. Does the original piston rings calculate out correctly using that formula? There is mention of a reduced radial thickness or "back-cut" ring used in heavy duty pistons or for use when desiring a less ring load on the wall but no mention of an amount or a formula.

Posted on: 2013/3/16 16:39

|

|||

|

Howard

|

||||

|

||||

|

Re: piston ring size

|

||||

|---|---|---|---|---|

|

Home away from home

|

I just checked a set of Grants, a brand I have installed in the straight eights dozens of times with perfect success. The top and second ring both measured .162 wide, so your new rings will work just fine.

Your old ones have worn that much as they are supposed to. If I recall you had complained in another post of very slow cranking after installing the new rings. That is hardly surprising as there can be a lot of friction before the new rings seat. That being said, there are three things that can help: 1-make sure the grooves are completely free of carbon as a little bit will make the rings stand proud. 2- don't hone the cylinders with coarse stones. I often go back by hand with a red scuffy pad to smooth the finish in the cylinders after honing. Then clean the bores with soap and water vigorously. The pistons slide down the bore noticeably easier. 3) I always use a mixture of half oil and half STP as a cylinder lube, and in the piston grooves as well. The stuff is darn slippery. I even pour a bit on top of the pistons just before putting the head on. This gives great compression for an easy if somewhat smokey startup.

Posted on: 2013/3/16 19:15

|

|||

|

||||

|

Re: piston ring size

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Gentlemen,

Thank you for your responses. Ross, yes I did (after the first removal of the pistons) re-gap the rings, After the second removal I did get a groove cleaner and cleaned out the groove until they were shiny. I must get an new head gasket since the one I am using now has been on and off three times ( and the compression of #2 cylinder is 30 psi lower than the rest of the cylinders). But I feel better that the rings are within specs. I even went as far as polishing the outside edge of the rings on a wire wheel to remove the black oxide plating. I bought a starter on ebay last year, checked the inside, beautiful, no thrown solder or anything weird so I replace the brushes and I think I'll change out the starter tomorrow, get some STP (saw some at O'Reileys) and keep on trying. Thanks, again Casey Rog

Posted on: 2013/3/16 19:35

|

|||

|

||||

|

Re: piston ring size

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

The formula given for calculating the standard radial or "D" wall thickness is bore diameter divided by 22. Does the original piston rings calculate out correctly using that formula? Not exactly. The D-wall ring specification is only one of many from the SAE book. It was probably the most common ring specification for '50s-80s US engines, but since then has been mostly superseded by much thinner metric ring specifications. In any case, most Packard OEM used a thicker K-wall ring, for which the bore diameter was divided by 20. Most of today's repop Packard pistons are sized for D-wall rings, which as you mention is bore diameter divided by 22. FWIW, an OEM K-wall ring set won't fit the Egge pistons for a V8. The good news is the standard Ford/Chevy D-wall moly rings are much less expensive and much better than the old '50s iron junk. jack vines

Posted on: 2013/3/17 12:28

|

|||

|

||||