|

Re: What SINGLE factor MOST contributed to the demise of Packard?

|

||||

|---|---|---|---|---|

|

Home away from home

|

steve 203,

sounds like out elected.

Posted on: 2015/3/1 18:38

|

|||

|

Riki

|

||||

|

||||

|

Re: What SINGLE factor MOST contributed to the demise of Packard?

|

||||

|---|---|---|---|---|

|

Home away from home

|

<i>Studebaker's handling of their 1953 line is a textbook case of mismanagement. After much dithering whether to field an all-new car for their 1952 centennial, the 1953's became a patchwork mess.</i>

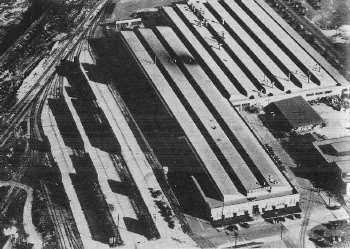

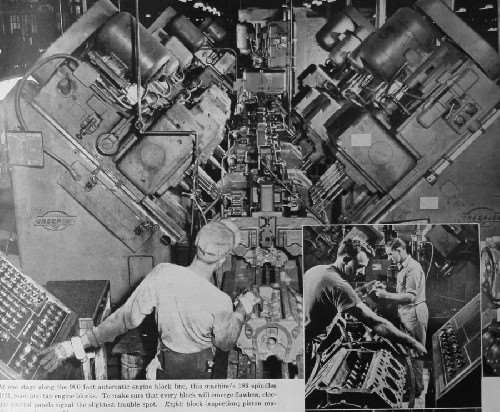

Another case of glassy-eyed management being sold on something that isn't well thought through. In this case sold by Lowey, like Nance being sold on the Conner move by Walter Grant. <i>...along with antiquated plants and clueless management......</i> Vance and Hoffman were ready and willing to step aside, and let Nance be the big honcho, which no doubt, appealed greatly to Nance and his Peterbuilt sized ego. As for Studebaker's facilities, here is what they had beside the antiquated and chaotic downtown assembly complex: 1st: Chippewa Ave, maybe three miles south of Plants 1 and 2. Built during the war for aircraft engine final assembly. 1M sq ft. On the top edge of the pic, you can see the edge of plant 8, which was used for service parts. 660,000sq ft. To this day, there is still plenty of vacant land for expansion around this location. 2nd: Vernon CA. Build in the mid 30s. Required semi-finished bodies be shipped by rail from South Bend. 406,000sqft 3rd: Hamilton, Ontario. Contained body plant. Converted WWII vintage war plant. 325,000sqft 4th: North Brunswick NJ. Built in 1950, sidetracked for J-47 part production. By the time the J-47 contract was cancelled in 53, Studebaker did not need the extra production capacity so the plant was sold, having never built a car. 450,000sqtf 5th: V8 block machining line in South Bend plant 2 complex. State of the art in the mid 50s If Studebaker management had been willing to phase out the obsolete Plant 1 and 2 assembly facilities in favor of taking the money spent on North Brunswick and expanding Chippewa, they would have had a more efficient operation.

Posted on: 2015/3/2 14:06

|

|||

|

||||

(113.00 KB)

(113.00 KB)