|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I can provide the photos of how it is supposed to actuate but don't have a resolution for what is not happening at the moment -- other than it is probably an issue with linkage. When I went to take the photos I realized I would have the same problem.

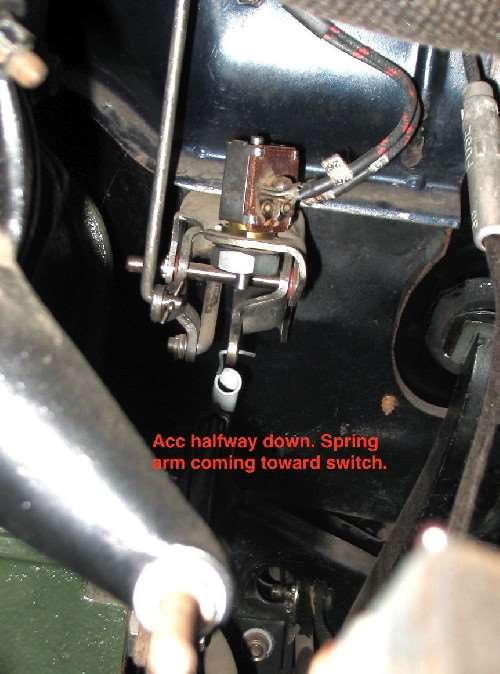

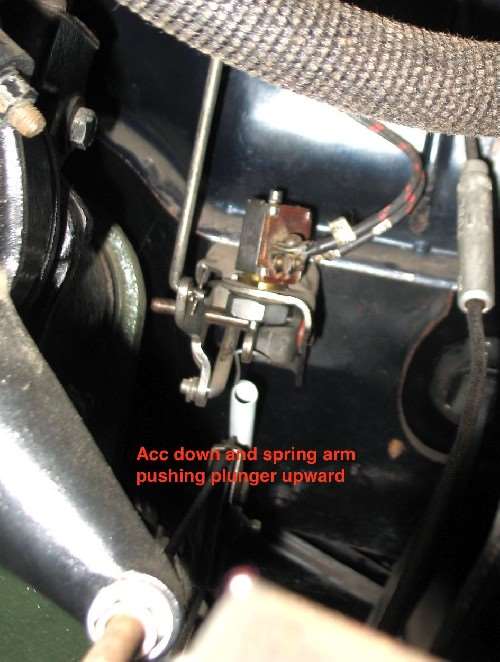

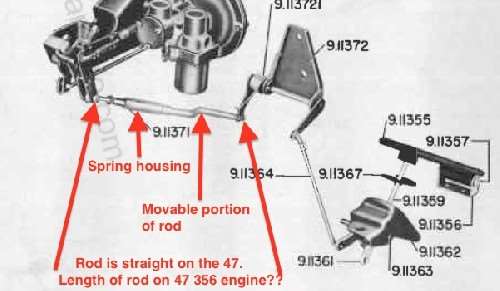

If you don't have EC then you only have a couple of places to check or adjust. With EC there are three or four that could be misadjusted. Don't remember if your car has the Electromatic but if it does and is known to be stock original then I think it is adjustment. I know my EC was off the car and in the trunk along with a couple of partial units so my issue is probably mismatched linkage. If yours came from another car it could have that issue too. There are various lengths of one rod for the different engines as well as different lengths for cars with EC only and for those with EC and OD. Not sure of the arrangement on non EC cars but with EC that same rod also has a spring mechanism in the end to allow the accelerator to move past the point the throttle is wide open so it can activate the OD kickdown switch. Make sure the spring portion of the rod is functional and the movable portion of rod has not seized. The EC accelerator switch also needs to have the arm in the proper position with the lever in front moving outward and up. If it has accidentally been reversed so the lever is pointing toward the firewall the engine will still start and drive but the lever hitting the firewall prevents the accelerator from moving far enough to hit the kickdown sw. The first two photos show the accelerator arm moving toward switch and actually moving the plunger. The third photo is the main rod. There is a compression spring in the housing and the movable portion of rod compresses it approx 1/2 to 3/4 inch to let the acc arm push against the kickdown sw plunger. If anyone has a stock EC with the 356 engine I would sure appreciate knowing the length of the main rod between the EC mechanism and the accelerator bracket on the firewall.

Posted on: 2015/8/25 10:58

|

|||

|

Howard

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thank you Howard, that is very helpful and I'll compare this weekend and I'll get a photo of my current set up.

My car doesn't have EC. Thanks again.

Posted on: 2015/8/25 16:52

|

|||

|

1963 Morris Cooper 997

1969 Austin 1800

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Home away from home

|

Here is my current setup, looks all to be there, however I seem t have an alignment issue. The bracket looks bent on the RHS.

Posted on: 2015/8/26 17:31

|

|||

|

1963 Morris Cooper 997

1969 Austin 1800

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It is either bent or the hole the pivot pin uses to support the bellcrank is seriously worn on one side. As thick as that bracket is it would probably be a project to try and bend or repair it where it lies -- although if there is no other damage on the bracket maybe the arm with the spring could be bent over a bit using heavy pliers.

If it were mine, while it is a bit of aggravation to remove the top of pedals and accelerator bottom hinge bar I would do that to access the bracket. That way I would be able to check the condition of the pivot and see what is bent. The only issue to think about if removing pedals might be the condition of the accelerator pedal. If the rubber is old and dry the rubber socket for the end of the stem which goes thru the floor might pull off when you pull to release the stem ball from the pedal. If you decide to proceed, once the pedal tops and acc are off you can pull the carpet back and remove the screws holding the assy to the floor. Then you could remove and examine the bracket and repair things properly.

Posted on: 2015/8/26 17:42

|

|||

|

Howard

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Home away from home

|

I finally got around to removing the mechanism, and only a slight adjustment was required to align the kick down switch plunger. However when all was reassembled, with the accelerator pedal fully depressed, it does not have enough travel to dis-engage the kick down plunger. We are only talking about a couple of millimetres.

Is any adjustment available on the throttle actuation mechanism available?

Posted on: 2015/11/15 20:40

|

|||

|

1963 Morris Cooper 997

1969 Austin 1800

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

By disengage I take it you mean the acc needs a bit more travel to fully depress the plunger? If so, the only linkage adjustment is either at the clevis at the carb side or the spring loaded adjusting turnbuckle type mechanism on the rod between the firewall bracket and the engine or EC bracket. Exactly what adjustment is available differs by engine. Adjusting those and particularly the clevis at carb side you have to make sure the carb rod moves far enough to engage the starter switch yet is not so short as to prevent the throttle from closing. Clevis side is affected by the turn buckle adjustment so is kind of a trade off of adjusting one and checking or compensating the other.

If you have the EC there are some other adjustments but those require some finesse and need to be done in an order and amount detailed in the service or training manual. Also if you have EC make sure the rod and lever for the accelerator switch is pointing toward the front, not toward the firewall. Is there a chance the kickdown switch can be moved? If the R9 switch maybe not but some replacements have a longer stem and a nut on both sides of the bracket. By adjusting the nuts the switch can be raised up or down slightly. Also, is there a chance the carpet or something under it is preventing the accelerator from going down any farther. There should be a phenolic plate around the accelerator stem which is sort of a dust and air seal. Some of those have wound up on the wrong side of padding or carpet and block the accelerator from going down farther.

Posted on: 2015/11/15 21:06

|

|||

|

Howard

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Home away from home

|

I realize this is an old thread, but was wondering what was done to fix the problem? A friend of mine is experiencing the same problem with his kickdown switch on his 49 Packard with the R11 overdrive. There is no vertical adjustment and the acc. rod doesn't hit the kickdown switch plunger. I don't think a Studebaker switch (has longer threaded mounting) would work because the thread size is 7/16 vs Packards 9/16. Anybody have additional ideas? Thanks

Posted on: 2016/7/10 15:57

|

|||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

IIRC, the pad or part of the accelerator linkage which is supposed to hit the plunger was bent on this car and not making contact. I believe the bent part was straightened and all was made to work. As far as travel, there is a bit of touch and go adjusting one of the link adjustments for a bit more travel in one area and shortening the other one so the carb still has full range.

Does your friend have an EC? If the arm on the accelerator switch is being pushed toward the firewall and not the engine, the EC will work but when lever hits the firewall it will not allow enough continued travel for the kickdown switch.

Posted on: 2016/7/10 16:44

|

|||

|

Howard

|

||||

|

||||

|

Re: 21st series R9 overdrive kick down switch

|

||||

|---|---|---|---|---|

|

Home away from home

|

My friends car does not have EC. The linkage looks straight but the end of the lever is just about an 1/8" from kickdown switch plunger, with acc pedal to floor. I have seen a Studebaker kickdown switch which has a longer threaded mounting which would give vertical adjustment, but I think the threads are 7/16 and not 9/16 like Packard. I would love to use the Studebaker switch because it is cheaper.

Posted on: 2016/7/10 17:39

|

|||

|

||||

(86.69 KB)

(86.69 KB)