|

Re: Survival revisitted

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

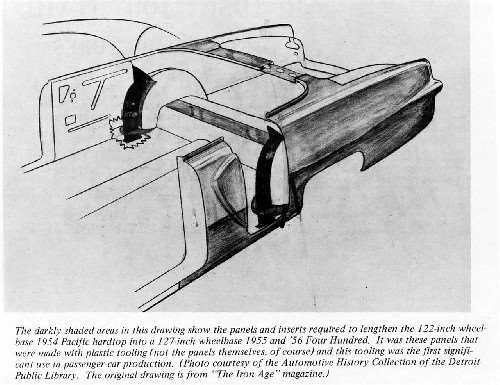

The article in The Cormorant about the use of "plastic tooling" to extend the 54 hardtop and convertible to the 127" wheelbase for 1955 was by George Hamlin and published in the Summer 1975 issue (thanks to Stuart Blond for digging up that info). The article itself is copyright protected but this illustration from "The Iron Age" magazine was included and shows how it was accomplished.

Posted on: 2016/4/6 8:15

|

|||

|

||||

|

Re: Survival revisitted

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Ross wrote:

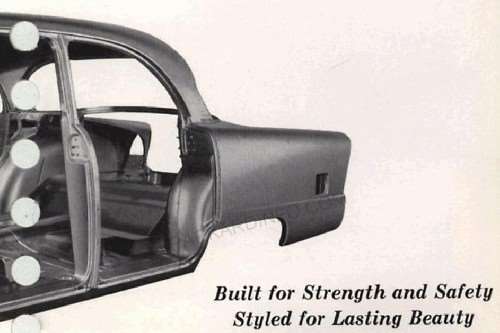

Quote: Even the rear door skins were stamped on the same die, they were just "short sheeted" and trimmed for the juniors. I agree - at least for 56th Series. What the casual observer may not know is that there are several dies involved in producing any deep-drawn sheet metal part. Not only are seperate sets of dies used for forming, punching, and trimming operations, but several sets of dies may be required just for forming - depending on the complexity of the shape. I watched this, decades ago, on a tour of Chrysler's Twinsburg, OH stamping plant. Watching the panels being flipped from one die to the next so fast that it reminded me of someone rolling a coin across the back of their knuckles. So, I can see where a rear door outer panel stamping destined for Junior, rather than Senior, would be diverted to a set of punching dies that excludes the pocket/opening for the courtesy lamp, then - if not simply "short-sheeted" - a set of final trimming and forming dies to establish the alternate perimieter and upset the edge (which would later be folded over the flange of the inner panel). While this works perfectly for 56th Series, where the bulge is the same shape betwen Junior and Senior, the 55th Series Junior panel carried the lines from the 54th Series. They must have retooled forming dies for 55th Series Seniors, then extended that to include Juniors for 56th Series. Bottom line, this example of production engineering was smart and economical, while delivering pleasing aesthetics.

Posted on: 2016/4/6 8:41

|

|||

|

||||

|

Re: Survival revisitted

|

||||

|---|---|---|---|---|

|

Home away from home

|

Today's market shift back to taller vehicles is reminder that not everyone back in '57 may have wanted a super low car. Here's a work-up that keeps Packard's taller height and instead works on proportions, with five inches added to rear overhang and front axle-to-dash. Reverse doors only if front-hinged could not have been made to work. Most of the body dies would have been carried over, several modified and only the hood and front fenders made new. Like the 1937 Seniors, these cars would have won not with the latest styling trends but with styling refinement and advanced engineering. Together with a Studebaker-based Clipper would have made for a fairly fresh showroom.

Posted on: 2016/5/1 6:43

|

|||

|

||||

(49.06 KB)

(49.06 KB)