|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

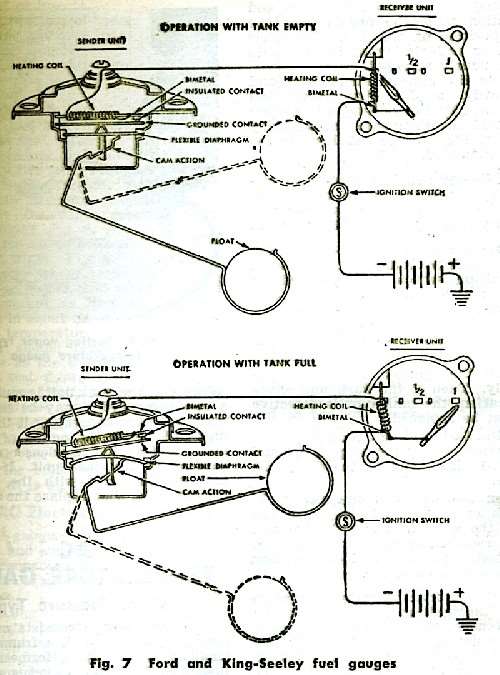

Here is a schematic and writeup on the operation along with some testing procedures for the 48-50 King-Seeley fuel gauge. It is out of an old 20th edition of Motors Auto Repair manual. It might help you or your mechanic figure out what is happening with yours.

On a gauge that always reads in one place mid scale, typically it is the sender unit that is the problem. Perhaps the float has jammed or something has become disconnected in the linkage that connects the float to the cam or eccentric so that it cannot change the pressure against the bimetal strip in the sender. Gauges do burn out but unless the needle was damaged and jammed at the time, when a gauge burns out usually it will not move off one of the end positions. Now is about the time a nice access hole in the trunk floor starts to look good. Authentic or not, I am a firm believer and have made access openings in my cars. Here is one I did in the 47. It will be covered with carpet and will not even be visible.

Posted on: 2016/12/26 14:52

|

|||

|

Howard

|

||||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Howard for all the information. I was afraid of that huge job to pull the sending unit. I guess I will take it back to the electrical shop that put in my sending unit a couple years ago. Maybe they can mark the floor to get a location for the hole you suggested I cut in the trunk floor.

Posted on: 2016/12/28 0:28

|

|||

|

Fred Puhn

|

||||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I believe the trunk floor of the 50 is similar in construction to the 47. If so there will be a small bulged up area about 2" in diameter on the floor above the sender. If your car has that bulge I expect the sender will be almost directly under it.

The bulge is to give extra clearance for the wire terminal. On the 47 the terminal is toward one side of the sender so the actual sender is located about 3/4 inch to the rear of the center of the bulge. On yours with the more centered terminal I expect the sender will be almost directly under the highest part of the bulge. You might have your mechanic check that location for starters and then adjust the hole to the front or rear to match the actual sender body. I cut the opening with a 3 1/2" hole saw. Used a flanging tool to make a slight depression around the circumference of the hole so the cover would fit flush with the floor. Then cut a plate out of 16ga sheetmetal to fit the flanged circle. Cutting the circle with a 4 3/8 hole saw gave me the proper size for my flange but that would vary depending on what was done to the hole. Because the bulge is no longer present, any heavy weight in the trunk could depress the floor enough to touch the terminal. To help prevent that I used the hole left by the center drill in the hole saw and added a rubber bumper to the plate. The bumper will come to rest on the sender before the floor and plate could move to touch the terminal. Glued a layer of sheet rubber on the plate as extra insurance and also act as a gasket to the floor. My hole wound up at the very end of one of the small channels in the trunk floor. That left an opening the cover wouldn't close so I bent the floor metal up so end was flush with the flanged portion of floor. That let the cover close the opening completely.

Posted on: 2016/12/28 11:56

|

|||

|

Howard

|

||||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Home away from home

|

With all due respect for Howard's profound ability to keep Packards alive, my first thought was that simply and carefully loosening the two straps and dropping the tank might be easier than cutting an access hole, then sealing and patching it.

Now that I have my own 23rd series with a non-functioning gauge or sender, this topic is germane to me. In my trunkload of spare parts from the previous owner I have a NOS box with a King Seely fuel gauge (with a bent needle) that may either be the original, a swap meet part or the old broken one that was replaced. I also have a fuel sender unit of unknown history that looks to be in good shape. But the mystery deepens because the previous owner replaced the Packard tank with a slightly smaller Chevy tank, so which gets the sender unit will be determined by whether it fits or not. One of the 1956 cars also lost a functioning fuel gauge when I filled it up over the summer and suddenly nothing registered. Magically, it began working again for a few days and then quit and apparently died. Perhaps a loose connection or stuck float, not at all moved by slapping the bottom of the tank with a board. Both of these will wait until warm weather returns. The joys of 60 and 65 year old cars! Our family VW and Audi late model cars conveniently have their high pressure, in-tank fuel pumps located under the back seat, with a convenient body access panel that makes pump replacement a 45 minute job. Our Chevy truck fleet of older pickups tells us that a pump might last 200,000 miles, but the easiest way to replace them is not to drop the heavy 26-33 gallon tank, but to take out and loosen the pickup bed body and tip it up with a couple of boards to gain direct access to the top of the tank. Doing it this way, our guys say it takes them about 90 minutes to replace a pump.

Posted on: 2016/12/28 17:57

|

|||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I already had the tools and the tank was out so adding the access hole was not a big deal. If I had worked at it solidly it would maybe have taken an hour. I was experimenting with different senders so did not want to drain and drop the tank each time so that was a big factor. I know many other mfgs of the period also had no access holes but still think that is something all mfgs should do.

Even more so on modern cars. I envy you the VW setup with an access panel. I am in a long drawn out process of changing the fuel pump on my 99 Ranger. Laying on my back and working with arms raised, I cannot do anymore. The rain we have had floods my work space several days at a time so also slowing it down.. With a work period of 10 minutes labor followed by a days rest, suffice it to say the removal and install is taking awhile. Tank is out now but is awaiting a hose I decided to change at the last minute. Maybe by summer it will be done. Back to the access panel. The Ford tank has to come out of the truck -- or the bed has to come off, take your choice. That part is not so bad but the hose connections are on the top and have to be removed before the tank can drop more than a few inches. Those modern push on type connectors are a pain -- even with the proper release tools it is hard to work with them. Can't see them and can barely get a hand in to reach them. If Ford had just put an access panel in so the hoses only could be disconnected quickly from the top the rest of the job would be done in a flash. Give me a Packard any day. It is too bad the Packard senders are not the same in 48-50 as the ones used 51-56. The early ones are the bimetal type and expensive. AFAIK, NOS are not that easy to come by and forget about repros. If yours cannot be rebuilt, there is a poster on the PAC forum who may have found a modern straight resistance type sender that will work. He found one that reads right on the gauge but I don't think he has the car running yet. The bimetal sender is on/off with a cooling period in between for the gauge. The straight resistance is on all the time so whether the gauge will be stable or, with the current on all the time, continue to climb thus reading high is an unknown.

Posted on: 2016/12/28 18:39

|

|||

|

Howard

|

||||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Home away from home

|

On a non-Packard current topic, I fully agree with Howard that the Quick-Connect/Disconnect features of newer fuel lines are a pain, especially to old guys who are used to doing connections the old fashioned way. Put those same connector tools in the hands of younger guys who have no experience with our old ways, and they make it look easy. Someday, both of us may be convinced our old hands can do it, too.

If I understand the X-parts exchange, a Fifties Ford sender unit may fit and work the Packards built 51-56. I may find that out personally once I drop the 56 tank in the Spring. Knowing that the older K-S gauges require a bimetal sender was valuable news to me. Until Santa has the cash in hand if I have to buy an expensive bimetal one, keeping track of miles driven and premature filling will be the rule for both old and older Packards. It's too bad that both 56s are nice cars because the temptation to cannibalize might take hold. None of them is driven so far that we cannot deal with not having a working gauge.

Posted on: 2016/12/28 21:58

|

|||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I could never understand why North American automakers don't provide an access hole to replace electric fuel pumps and senders. In the old carburetor days with the mechanical pump up by the engine it might not have been seen as a convenience since sender units are pretty reliable. All of my European and Japanese cars (BMW, Mercedes Benz, Toyota, Mazda) have had a convenient access hole. My Ford Crown Victoria fuel pump can be changed without dropping the tank but that seems to me to be an anomaly on NA cars.

Posted on: 2016/12/29 12:31

|

|||

|

______________________________________________

Dave |

||||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Home away from home

|

It's called value engineering today. It was being perfected around the time of this car. By GE if I recall. I have the books.

The sender life is pretty good so to add cost for a means to replace it, is not cost effective/adds no value to the car or the selling entity. The tank assembly is mounted to the frame. The body was dropped from above, so no need for a sending unit mounting hole. You have to put it all into context, remember, we're way past the design life of these cars. They didn't even have a good idea about design life in those days. It was post war crank this model out and get on to the next one thinking. Anything based a heat cycle for operation is going to fail at some point. So either upgrade or get prepared for more frequent and costlier repairs as the supply shrink. Japanese have always been a bit more empirical in their manufacturing approach and for solving problems. They were taught this after the war. They used those methods to compete and win during the demise of US car quality in the 80's. If someone on the line or a factory repair mechanic suggests they need an access hole to do a better install job, they'll probably put one on after consultation.

Posted on: 2016/12/29 21:20

|

|||

|

||||

|

Re: Fuel gage problem. on Series 23

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well what ever your opinions are concerning putting an access panel to the fuel tank sending unit, I put one in anyway. I thought it would be easier than raising and lowering a tank with gas in it. My Packard is a '49, 2392.

A couple of pictures in case you are interested.

Posted on: 2016/12/29 21:43

|

|||

|

[url=http://packardinf

|

||||

|

||||

(102.67 KB)

(102.67 KB)