|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I really admire your skill and craftsmanship! When I did my running boards on my 34 many decades ago, I needed to fabricate the pieces that went between the fender ends and the board - you did a far better job than I did.

Posted on: 2014/3/14 14:21

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

O-D,

Thanks for the compliment. I was lucky the I had the two outside pieces of trim and that they were made of brass avoiding that dreaded enemy of rust. I installed the running boards this weekend. The left side looks good, but I'm not happy with the right side. Sometimes it seems that a part gets installed and when it comes to installing the next it needs to come off and either be adjusted or something else needs ot occur. In this case, the right running board went back on and all the bolts on both right fenders needed to be loosen. Oh well, having most of the "Honey Do's" under control, it's nice to be able to commit some time to the project.With the fenders, hood and running boards on the project is starting to look like a car. However. the top two hood pieces look like they are going to present a major challenge that I\'ll present to this forum to get some input who have travel the path before me. Next weekend looks to be a good one to fire up the RV and head towards California's Central Coast area A.K.A. as one of the country's wine producing regions. And yes I do drink wine.

Posted on: 2014/3/16 19:18

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

I would appreciate ideas and input on how to handle fitting the top right and left hood panels. First let m me provide some history about the car.

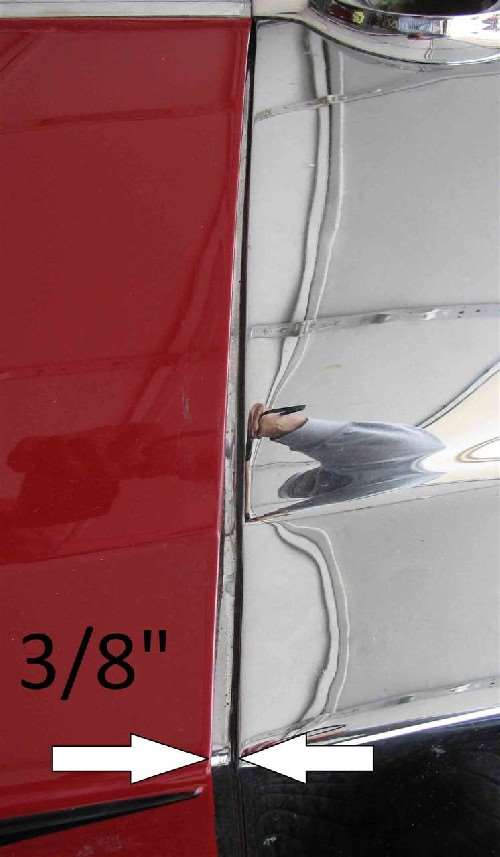

I took over the restoration from an individual well versed in restoring cars. He was being assisted by a person who does his own restorations and has finished second at Pebble Beach behind the Nethercutt. When I bought the car he had some of the major pieces in final paint (the 4 fenders, 4 hood pieces, and splash aprons) in the color he was restoring to (Packard Blue & Black). The body in primer (while still in need of more attention like replacing several rusted out areas, primer and block sanding) was bolted to the frame with doors on and the radiator in place. After getting the car home, I started on the rest of the body assuming that since the hood was in final paint it would fit correct (silly me) without checking the fit. Now I have had the entire car painted in the color of our choice (Carnival Red, a 1931 Desoto color and Black). I've had problems fitting the two top panels of the hood where they meet the radiator cowl. When the gap in the hood's center between the panel and cowl touches the cowl there is 3/8" gap at the outside on both right and left sides. The rear of the top panels is consistent. Right now my thought is the top two panels need to be cut along the front edge to provide a consistent gap. This would entail going from 3/8" starting inside edge of the hood and going down to 0" at the outside. At this point, the radiator and body can adjusted to provide a good fit. It would mean that the blades on the water pump will be between 3/8" and 1/2" from the radiator core. I've included a couple of pictures to show what I'm talking about. The big question I have is there something that I'm missing on the entire problem in trying to align the panels????

Posted on: 2014/3/23 12:29

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Martson:

That is a huge problem. I assume the cowl has an even gap so the problem is the radiator shell. Is the car an early or late 9th series. A late car has vacuum clutch, three speed trans, and can have a different shell. A very late car has a chrome center strip down the center. It may be that you have the wrong hood. Or maybe a shell that is from the 8th series conversion kit.

Posted on: 2014/3/23 18:01

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

Marston,

Is the radiator mounted on the proper thickness rubber washers? There should be a rectangular rubber washer between each one of the threaded studs protruding out of the bottom of the radiator assembly. If the radiator is not at the correct height the gap between the hood and radiator shell will not be even. Raising the height of the radiator will increase the gap between the shell and hood at the top front and decrease the gap at the bottom front. I've attached a few pictures of my '32 that may help. Attach file:  (103.83 KB) (103.83 KB)  (99.50 KB) (99.50 KB)  (110.69 KB) (110.69 KB)  (96.89 KB) (96.89 KB)  (110.88 KB) (110.88 KB)  (94.48 KB) (94.48 KB)  (94.15 KB) (94.15 KB)  (73.97 KB) (73.97 KB)

Posted on: 2014/3/23 20:26

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

A few more...

Posted on: 2014/3/23 20:29

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

I really appreciate your inputs. The car has a three speed transmission, the shell does not have a center bar, no vacuum assist, the radiator has been tried with and without the rubber, and the gap between the other various other parts has in general been a consistent gap (see photos),. Based on the car's engine number (343292), it would be near the middle of the production sequence.

I'll measure the panels and post the data here and maybe I can get some feedback as to whether or not I have the correct hoods parts. How can I determine if the shell is correct? I can't work on the car until Thursday, but plan on moving the body as far forward as possible. Then, if I can get the distance between the fan blades and the radiator core greater than 1/2", I may decide to cut the two top panels to fit depending on how everything fits.

Posted on: 2014/3/24 19:40

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

I unbolted the body and moved it forwards as far as possible. I gained maybe a 1/8 of an inch, but not enough that I would feel comfortable trimming the top panels. I'm concerned that the blades from the fan would be too close to the radiator.

Next I think that I'll work with the shell to see if it would be possible to move it towards the rea of the in order to gain some additional clearance for the fan blades, which would allow me to trim the top two hood pieces. In the interim, I've been working on the trunk rack and the right & left frame brackets. They needed priming, body filler to take care of a few areas that were pitted from. The parts were then sprayed with base coat and then 3 coats of clear. The rack turned out nice looking, but I'm not happy with the right bracket, a run that did not look good after color sanding. So I'll give them a light sanding with 1200 grit Wet Or Dry paper and re-shoot the clear. Both trunk rack brace joint assemblies need to be chrome plated and I could use some input. I tried to push the pin out using a vice but ran into more resistance than I thought would be required. Has anyone out there done before and are there any thoughts on how best to do it (or maybe not do it)? Also, the 5 stainless steel trim pieces have a few dents and two have areas where they have been partially crushed. It appears that I should be able to "un-dent and un-crush" them. At that point, they should buff and polish up nicely. Another question that I have is what type of connector it used to install the trim pieces and are they available somewhere.

Posted on: 2014/4/21 23:17

|

|||

|

||||

|

Re: Our 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

Last weekend I finished realigning the doors after moving the body forward and can now proceed. Raising the radiator helped on the gap at the front on the top two pieces, but hurt elsewhere. Also, it appears that the radiator shell is back as far as possible so there's nothing to be gained there. Therefore, I set about working on other things while I investigate the hood gap problem some more.

In need of shoulder rivets for the 8 hood side doors (8 with a long shoulder and 8 with a short shoulder) I searched and found a source for them at $12.50 each. With an extra one of each size for insurance, this would have been a $225.00 hit for several ounces of brass. Therefore, I thought maybe a shoulder screw would work and found some in stainless for $1.00 each, but didn't like the look. So I set about making shoulder rivets myself on a lathe. I bought a short piece of 5/16" brass rod. Turned a prototype of each and then adjusted my measurements estimates. The first 2 or so took about 15 to 20 minutes each while the final ones were clocking in at less than 10. I made the 8 brackets that hold the locking mechanism on the side doors from 16 gauge steel as the ones I had were fairly well rusted and I only had enough for one side.. To form the "U" bend in the bracket I made a die from a piece of 5/8" thick aluminum flat bar by drilling a 3/8' hole right next to the side of the bar. The hole was opened up so it was "U" shaped (see photo). The holes on both sides of the "U" are guides for drilling the holes in the bracket. One of the photos shows the bend being formed using the die and pressing a 1/4" rod into the slot with a vice.

Posted on: 2014/5/12 18:18

|

|||

|

||||