Re: Steering wheel horn push

Posted by HH56 On 2016/8/31 10:31:41

Thanks for mentioning the paper gasket. Not sure how yours is positioned but I had forgotten it was required on some wheels and since I am transferring my old ring to a new deluxe wheel I need to make one for mine.

The stock wheel has a plastic or hard rubber hub with only the center portion where the shaft is fastened being metal. As Wes's drawing shows, nothing extra is required on those wheels. The deluxe wheels -- at least the K wheel -- has a metal hub and I wouldn't be surprised if others have a metal hub too. I know you posted a photo of your wheel and think it was a K but don't remember for sure.

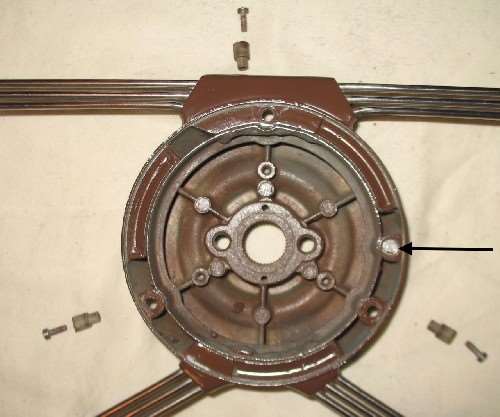

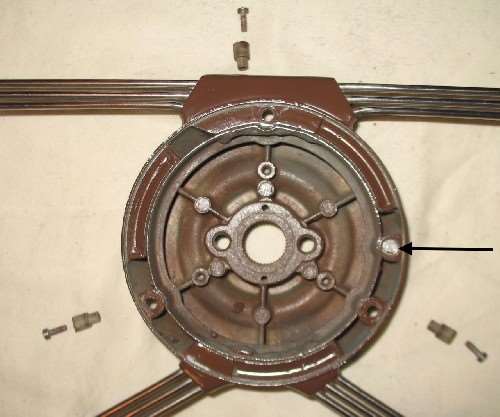

If your hub is metal there are some places to check for possible shorts. The three screws holding the ring to the hub have plastic insulators in the holes. Make sure those insulators are good. I notice one of mine has a section broken out on one side which could allow the screw head to touch metal under some conditions. That would cause the horn to blow. There should be a thin fiber or paper gasket between what I call the contact plate on the ring and the hub to prevent direct contact with the hub. Also, there is a locating pin on the contact plate and a corresponding depression in the hub (arrows) which keeps the ring from rotating. There needs to be some kind of insulator in the depression so the ring cannot rotate and have the pin touch the sides or bottom of the depression. It could be plastic or perhaps the paper gasket was formed with a shallow pocket around the pin to fit in the depression.

The deflection is not very much on my ring. I don't have a convenient way to measure the amount but it is determined by the wave washer spring and plastic insulator in the center. If you feel yours is too little possibly adding a thin gasket like a layer or two of paper in the rounded metal pocket between the black plastic insulator in the middle and the metal and also under the 3 black insulators would raise the contact plate a tiny bit and provide more clearance. You would not want to add much because that could increase the strain on the plastic and cause it to crack or deform the wire contact piece if it gets too tight.

Attach file:

(83.19 KB)

(83.19 KB)

(125.96 KB)

(125.96 KB)

(117.39 KB)

(117.39 KB)

The stock wheel has a plastic or hard rubber hub with only the center portion where the shaft is fastened being metal. As Wes's drawing shows, nothing extra is required on those wheels. The deluxe wheels -- at least the K wheel -- has a metal hub and I wouldn't be surprised if others have a metal hub too. I know you posted a photo of your wheel and think it was a K but don't remember for sure.

If your hub is metal there are some places to check for possible shorts. The three screws holding the ring to the hub have plastic insulators in the holes. Make sure those insulators are good. I notice one of mine has a section broken out on one side which could allow the screw head to touch metal under some conditions. That would cause the horn to blow. There should be a thin fiber or paper gasket between what I call the contact plate on the ring and the hub to prevent direct contact with the hub. Also, there is a locating pin on the contact plate and a corresponding depression in the hub (arrows) which keeps the ring from rotating. There needs to be some kind of insulator in the depression so the ring cannot rotate and have the pin touch the sides or bottom of the depression. It could be plastic or perhaps the paper gasket was formed with a shallow pocket around the pin to fit in the depression.

The deflection is not very much on my ring. I don't have a convenient way to measure the amount but it is determined by the wave washer spring and plastic insulator in the center. If you feel yours is too little possibly adding a thin gasket like a layer or two of paper in the rounded metal pocket between the black plastic insulator in the middle and the metal and also under the 3 black insulators would raise the contact plate a tiny bit and provide more clearance. You would not want to add much because that could increase the strain on the plastic and cause it to crack or deform the wire contact piece if it gets too tight.

Attach file:

(83.19 KB)

(83.19 KB)

(125.96 KB)

(125.96 KB)

(117.39 KB)

(117.39 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=181223