Re: Vavlve grinding tools

Posted by Owen_Dyneto On 2014/10/27 8:39:01

Thanks for the photo. It's hard to estimate the depth of the damage to the seat from the photo but it looks pretty severe. You could grind away with valve lapping compound for a half a lifetime and doubt you'd get it cleaned up. Just a guess from what I see but I think the only "good" cure is to have a hardened valve seat installed and if you do that, you might just as well go ahead and do all the exhaust valve seats.

But if you come across a valve seat grinding tool set you might give it a try - I've never done one that bad. What will happen is as you grind the seat down to the base of the damage the seat will widen very much - perhaps to as much as nearly the full face of the valve and typically you want a seat width of about 3/32, more or less. Then you'll need a 30 degree (or in any case less than the seat angle) stone to narrow the seat which will involve the removal of A LOT of metal - hopefully not so much as to make the installation of a hardened seat problematic should your attempt fail.

As the seat lowers from grinding, the valve stem will of course sit lower in the block so as mentioned before, you may have to grind some off the end of the stem to get back into range of the lifter - no big deal there. Also as the valve sits lower, the spring tension will be decreased; for the low rpms most collector cars are driven that may not be a problem but should you be successful in restoring the seat, you probably should consider installing shims to the spring in an amount equal to the amount the seat was dropped.

The only other possibility I see is to locate one of those tools for cutting the block with the engine in the car to accept a valve seat insert but as I said I've searched without success for one of those tools (it was a Chrysler special tool) for 40 years and never seen one.

I wish I could be more optimistic, and best of luck with the outcome no matter which route it takes; keep us posted and let me know if I can be of any further help.

PS - I'm assuming it's an exhaust valve seat?

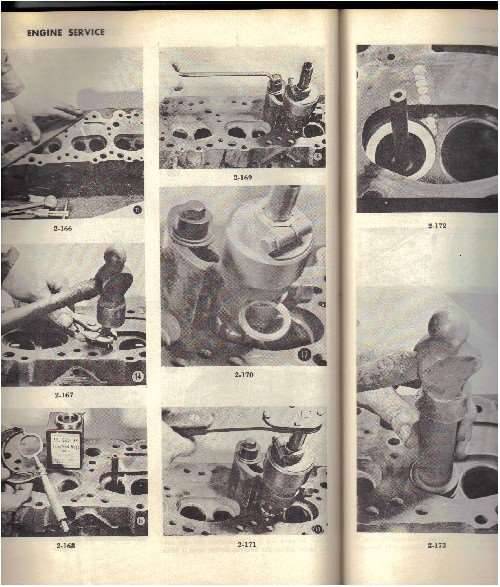

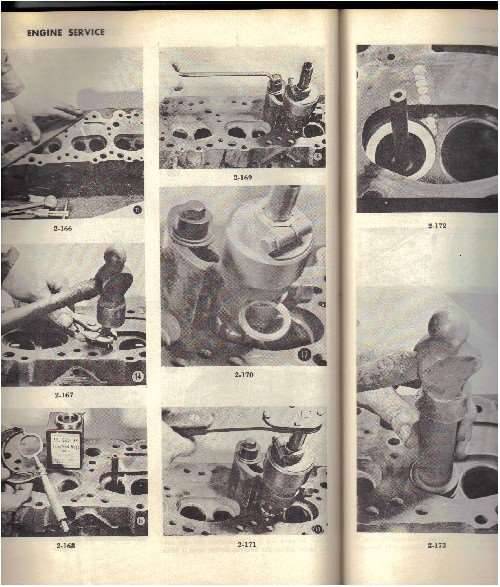

PPS - here's an excerpt from an old Glenn's which shows the tool and process for relief cutting and inserting a valve seat insert with the block in the car, so at least you know what the tool looks like. In the particular example the seat was inserted after a "stitching" repair of a cracked block across a valve seat which isn't relevant to your case but the process is the same. I've looked thru the Packard special tools catalogs, ditto for the Kent-Moore special tools and not seen the seat cutter listed so apparently it was not in wide use.

Attach file:

(149.58 KB)

(149.58 KB)

But if you come across a valve seat grinding tool set you might give it a try - I've never done one that bad. What will happen is as you grind the seat down to the base of the damage the seat will widen very much - perhaps to as much as nearly the full face of the valve and typically you want a seat width of about 3/32, more or less. Then you'll need a 30 degree (or in any case less than the seat angle) stone to narrow the seat which will involve the removal of A LOT of metal - hopefully not so much as to make the installation of a hardened seat problematic should your attempt fail.

As the seat lowers from grinding, the valve stem will of course sit lower in the block so as mentioned before, you may have to grind some off the end of the stem to get back into range of the lifter - no big deal there. Also as the valve sits lower, the spring tension will be decreased; for the low rpms most collector cars are driven that may not be a problem but should you be successful in restoring the seat, you probably should consider installing shims to the spring in an amount equal to the amount the seat was dropped.

The only other possibility I see is to locate one of those tools for cutting the block with the engine in the car to accept a valve seat insert but as I said I've searched without success for one of those tools (it was a Chrysler special tool) for 40 years and never seen one.

I wish I could be more optimistic, and best of luck with the outcome no matter which route it takes; keep us posted and let me know if I can be of any further help.

PS - I'm assuming it's an exhaust valve seat?

PPS - here's an excerpt from an old Glenn's which shows the tool and process for relief cutting and inserting a valve seat insert with the block in the car, so at least you know what the tool looks like. In the particular example the seat was inserted after a "stitching" repair of a cracked block across a valve seat which isn't relevant to your case but the process is the same. I've looked thru the Packard special tools catalogs, ditto for the Kent-Moore special tools and not seen the seat cutter listed so apparently it was not in wide use.

Attach file:

(149.58 KB)

(149.58 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=152022