Re: 1941 Packard horn

Posted by HH56 On 2018/11/10 14:26:23

Horns require a lot of current so make sure you are using adequate size jumper wires for testing. There is a set of contact points inside the horns that has probably oxidized or maybe pitted. They must be making good contact when they are closed so the magnet can start its action. If the relay is still in the circuit when you are testing, that too has contacts which could be problematic. You can remove the covers and see what the contacts look like and give them a dressing with a point file or burnisher.

Covers are usually a press fit and may have a groove or notch for a screwdriver to get under and pry it up. Usually those openings need to go back in a specific position when the cover is replaced so look for anything like that before removal. The points will be closed when the horn is just sitting and gap needs to be a specific distance when open for the horn to sound right.

You should not need to mess with anything adjustment wise but if it still doesn't work after cleaning the points possibly debris or water has gotten inside and rust has seized or filled the armature gap space so the magnet cannot attract the diaphragm and open the points enough to start the action. Another thing to check.

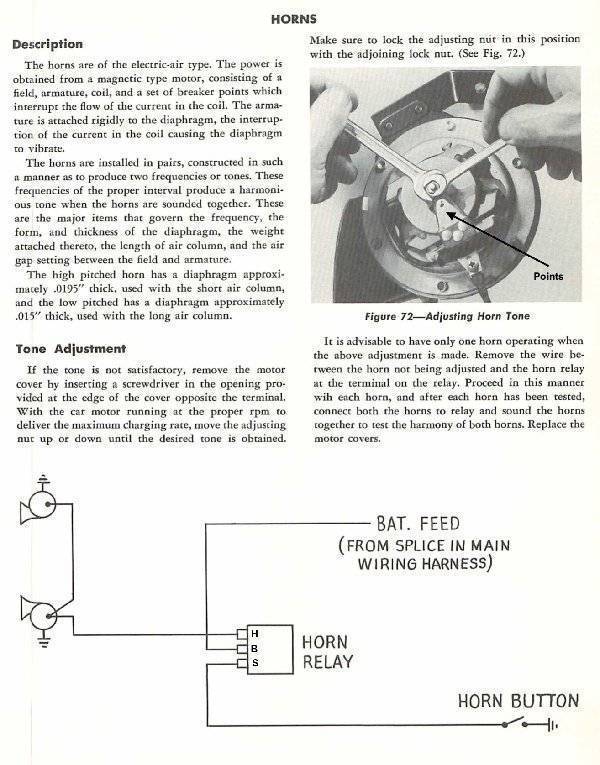

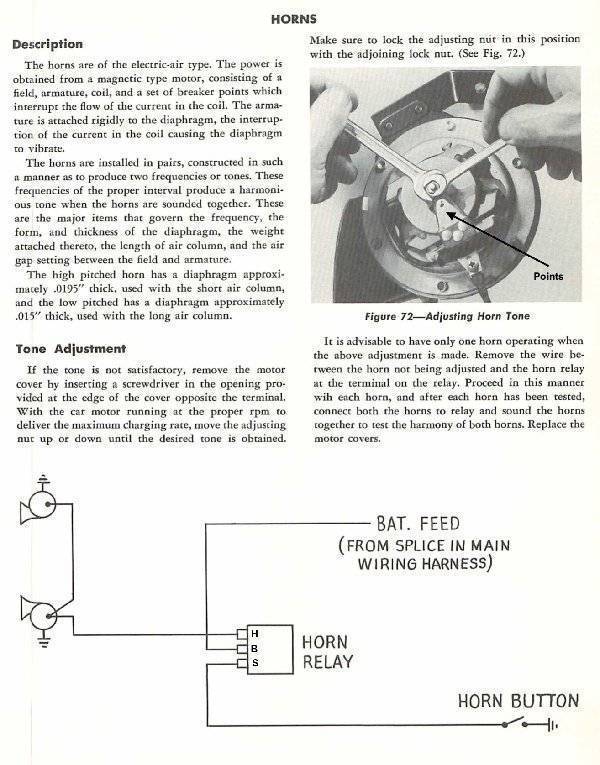

Here is a photo and adjustment description of a postwar horn. Internals might be a bit different in looks to yours but they all work about the same way so you should be able to identify the points and adjustment screws on yours if there are differences.

Attach file:

(194.16 KB)

(194.16 KB)

Covers are usually a press fit and may have a groove or notch for a screwdriver to get under and pry it up. Usually those openings need to go back in a specific position when the cover is replaced so look for anything like that before removal. The points will be closed when the horn is just sitting and gap needs to be a specific distance when open for the horn to sound right.

You should not need to mess with anything adjustment wise but if it still doesn't work after cleaning the points possibly debris or water has gotten inside and rust has seized or filled the armature gap space so the magnet cannot attract the diaphragm and open the points enough to start the action. Another thing to check.

Here is a photo and adjustment description of a postwar horn. Internals might be a bit different in looks to yours but they all work about the same way so you should be able to identify the points and adjustment screws on yours if there are differences.

Attach file:

(194.16 KB)

(194.16 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=207308