Re: 1929 - 30 restore camshaft journals and bearings with to much waer

Posted by 32model901 On 2011/5/21 7:05:32

2470Packard,

One thing to keep in mind when machining or grinding your cam journals, the cam bearings need to be line bored or honed to size, in the block, to assure they are all on the same axis.

If the cam bearings were machined with .001 clearance to the cam journals outside of the crankcase and then assembled the cam will be tight and you will not have the proper oil film clearance in the cam bearings.

Also the block needs to be torqued to the crankcase when this is done to assure the cam bearings will still be in line when the block is assembled to the crankcase.

One example of line boring equipment for cam bearings:http://www.sunnen.com/ProductDetails.aspx?ProductID=37&NavID=678

In addition to size, the machined bearing surfaces need to have the correct finish, taper, and out of round.

Links with some useful info:http://www.engineparts.com/publications/CL77-3-402.pdfhttp://www.mahleclevite.com/it_cambrgs.asphttp://www.mahleclevite.com/techbulletins/CL77-1-205R.pdfhttp://www.stealth316.com/misc/clevite-eng-bearing-fund-p2.pdf

Regards,

Dave

Attach file:

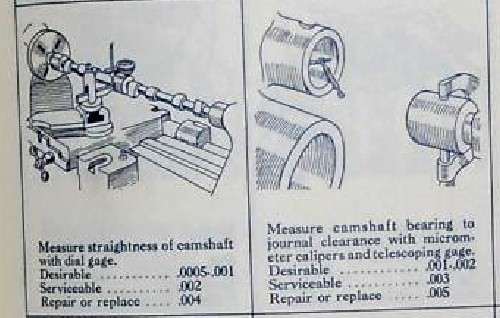

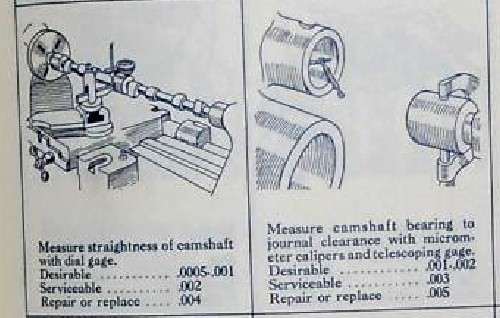

(41.29 KB)

(41.29 KB)

One thing to keep in mind when machining or grinding your cam journals, the cam bearings need to be line bored or honed to size, in the block, to assure they are all on the same axis.

If the cam bearings were machined with .001 clearance to the cam journals outside of the crankcase and then assembled the cam will be tight and you will not have the proper oil film clearance in the cam bearings.

Also the block needs to be torqued to the crankcase when this is done to assure the cam bearings will still be in line when the block is assembled to the crankcase.

One example of line boring equipment for cam bearings:http://www.sunnen.com/ProductDetails.aspx?ProductID=37&NavID=678

In addition to size, the machined bearing surfaces need to have the correct finish, taper, and out of round.

Links with some useful info:http://www.engineparts.com/publications/CL77-3-402.pdfhttp://www.mahleclevite.com/it_cambrgs.asphttp://www.mahleclevite.com/techbulletins/CL77-1-205R.pdfhttp://www.stealth316.com/misc/clevite-eng-bearing-fund-p2.pdf

Regards,

Dave

Attach file:

(41.29 KB)

(41.29 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=77222