Re: 51Packard's....51 Packard

Posted by HH56 On 2011/1/25 10:28:46

I'd be careful with the PB blaster or anything with a petroleum solvent around the wiring. If you can find some locally, the electric contact cleaner would be a better solution--the type that says no damage to contacts or plastic.

The windings themselves may not be hurt with PB because they are usually enamel or varnished wire but there may be some insulating tape or sleeving used that might be softened by petroleum. If you do have to use PB or something like it, try to keep anything you use confined to mechanical.

If the armature turns, the problem is most likely the brushes and commutator area being corroded and not making contact. That motor is pretty simple with only two field coils. One or the other coil is connected (depending on direction wanted) to switch and power. Both coils are connected at other end in series with armature and completes circuit to ground. If the motor was bound up, while unlikely, it is possible something has burned.

If you use the cleaner, you can spray the brushes and holders and make sure the brushes slide freely and springs are able to supply pressure. Once they do, reassemble to armature and spray some more on and rotate armature with brushes pressing against it. Clean the commutator and wipe up any old oxidized material with a rough paper or rag. Don't use anything like sandpaper on the commutator that will scratch it or leave something embedded in the copper.

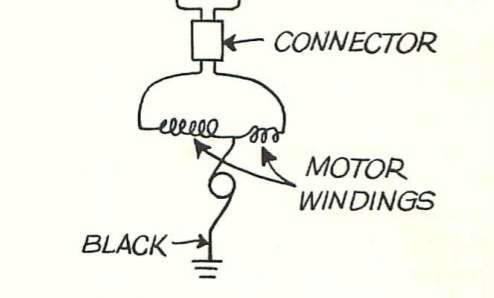

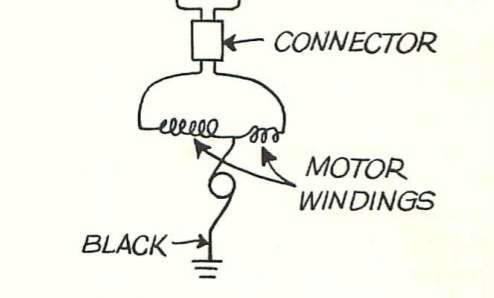

Here is a typical schematic used for antenna, window, TL and most other post 24th series reversible motors Packard used.

Attach file:

(10.57 KB)

(10.57 KB)

The windings themselves may not be hurt with PB because they are usually enamel or varnished wire but there may be some insulating tape or sleeving used that might be softened by petroleum. If you do have to use PB or something like it, try to keep anything you use confined to mechanical.

If the armature turns, the problem is most likely the brushes and commutator area being corroded and not making contact. That motor is pretty simple with only two field coils. One or the other coil is connected (depending on direction wanted) to switch and power. Both coils are connected at other end in series with armature and completes circuit to ground. If the motor was bound up, while unlikely, it is possible something has burned.

If you use the cleaner, you can spray the brushes and holders and make sure the brushes slide freely and springs are able to supply pressure. Once they do, reassemble to armature and spray some more on and rotate armature with brushes pressing against it. Clean the commutator and wipe up any old oxidized material with a rough paper or rag. Don't use anything like sandpaper on the commutator that will scratch it or leave something embedded in the copper.

Here is a typical schematic used for antenna, window, TL and most other post 24th series reversible motors Packard used.

Attach file:

(10.57 KB)

(10.57 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=69421