Re: 1940 Super 8 160 Model 1803 Project

Posted by Jim On 2011/12/29 0:12:34

West, if I end up using a mystery shaft from the January PI swap meet, then no pics, if it's the wrong length, then yes I will post pics as time allows. No, $75 - $100 is not at all out of line. $200 usually gets a brand new assembly with U-Joints.

So, I began by tearing down the trans to install the senior large input so it would work behind the 356. The farther I got in, the more sketchy things looked. I found that some parts had previously been replaced before the car was parked, others had not and were in terrible shape. The good / bad news is the relay has a break in the .010" electromagnet winding so the OD was inoperative. The OD section is virtually perfect but I have a bad relay. Looks like I'll be rewinding it one evening in the near future.

Upon inspection I discovered first / reverse slider had badly worn shift dogs from some jerk jamming gears along with the second / high syncro shifting collar. Not a real problem, I have good parts from a tranny that came with the spare Flackmaster found me in Oregon about 3 years ago. Thanks Dave!

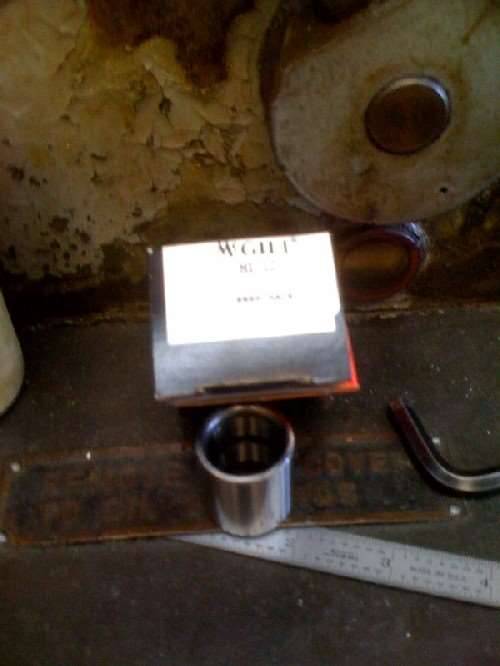

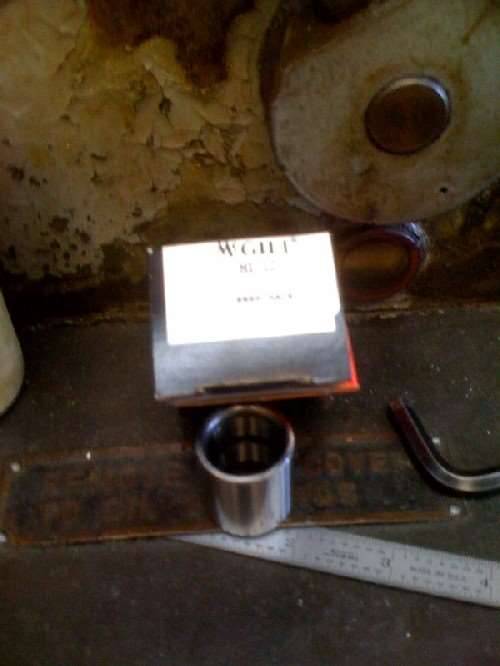

Next disaster was finding the mainshaft bearing surface the needle roller bearing runs on at the front end of the main shaft was half perfect and half pitted and badly worn. Looked like improper hardening from new. What to do??? The freewheeling first and second gears were perfect and they are held on with a swaged collar as Packard only sold this main shaft as an assembly. There is likely no storehouse with Packard mainshafts for transmissions equipped with R-11, so it's out to the lathe yet again. I located a bearing sleeve that is 1" OD X 3/4" ID by 1" long. Absolutely perfect! My buddy John brought some high speed carbide tooling over and we proceeded to cut through the hardened bearing surface and reduced the shaft size to accept the new bearing journal. As the tooling was cutting it became positively obvious there was an error in the hardening process as evident by the way the tooling cut on the unworn section v. the damaged section.

With the mainshaft salvaged, bearing fit, and input tested for fit, it was on to something a bit less stressful and a bunch easier to fix, a little switch so to speak. Read all about in the next installment of "How would anyone fix these cars without a machine shop in their garage".

Attach file:

(47.63 KB)

(47.63 KB)

(46.58 KB)

(46.58 KB)

(47.94 KB)

(47.94 KB)

(34.40 KB)

(34.40 KB)

(39.81 KB)

(39.81 KB)

(32.06 KB)

(32.06 KB)

(41.87 KB)

(41.87 KB)

(45.57 KB)

(45.57 KB)

(47.49 KB)

(47.49 KB)

(46.60 KB)

(46.60 KB)

So, I began by tearing down the trans to install the senior large input so it would work behind the 356. The farther I got in, the more sketchy things looked. I found that some parts had previously been replaced before the car was parked, others had not and were in terrible shape. The good / bad news is the relay has a break in the .010" electromagnet winding so the OD was inoperative. The OD section is virtually perfect but I have a bad relay. Looks like I'll be rewinding it one evening in the near future.

Upon inspection I discovered first / reverse slider had badly worn shift dogs from some jerk jamming gears along with the second / high syncro shifting collar. Not a real problem, I have good parts from a tranny that came with the spare Flackmaster found me in Oregon about 3 years ago. Thanks Dave!

Next disaster was finding the mainshaft bearing surface the needle roller bearing runs on at the front end of the main shaft was half perfect and half pitted and badly worn. Looked like improper hardening from new. What to do??? The freewheeling first and second gears were perfect and they are held on with a swaged collar as Packard only sold this main shaft as an assembly. There is likely no storehouse with Packard mainshafts for transmissions equipped with R-11, so it's out to the lathe yet again. I located a bearing sleeve that is 1" OD X 3/4" ID by 1" long. Absolutely perfect! My buddy John brought some high speed carbide tooling over and we proceeded to cut through the hardened bearing surface and reduced the shaft size to accept the new bearing journal. As the tooling was cutting it became positively obvious there was an error in the hardening process as evident by the way the tooling cut on the unworn section v. the damaged section.

With the mainshaft salvaged, bearing fit, and input tested for fit, it was on to something a bit less stressful and a bunch easier to fix, a little switch so to speak. Read all about in the next installment of "How would anyone fix these cars without a machine shop in their garage".

Attach file:

(47.63 KB)

(47.63 KB)

(46.58 KB)

(46.58 KB)

(47.94 KB)

(47.94 KB)

(34.40 KB)

(34.40 KB)

(39.81 KB)

(39.81 KB)

(32.06 KB)

(32.06 KB)

(41.87 KB)

(41.87 KB)

(45.57 KB)

(45.57 KB)

(47.49 KB)

(47.49 KB)

(46.60 KB)

(46.60 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=92016