Re: 1954 Clipper Deluxe Sportster

Posted by HH56 On 2015/10/12 17:05:52

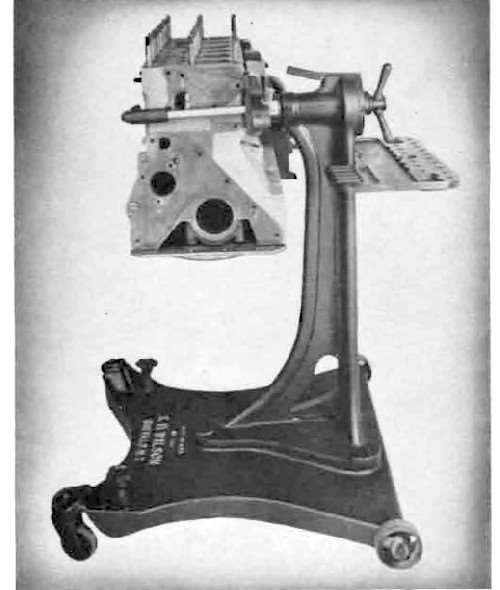

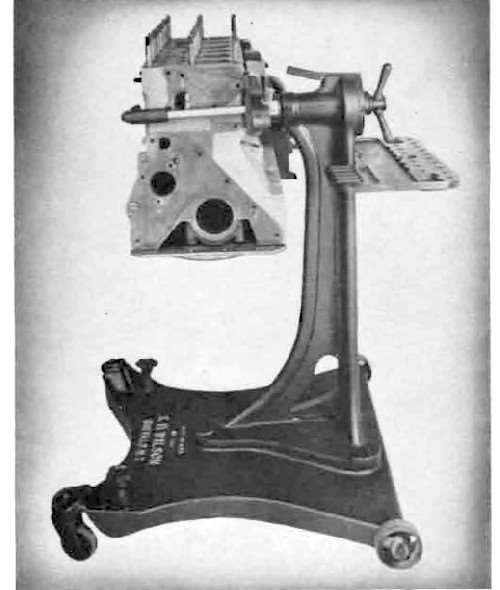

That is a considerable amount of weight and leverage to be supported from a few bolts on just one end. At the least if you are gong to mount it lengthwise I would try and figure a way to also support the front with some kind of removable piece. Some with longer engines and short stands have made a piece to fit between the floor to under the front of engine. Others have used some sort of wooden box or crate and shims and others kept the cherry picker attached to the front. Downside to those methods is the support has to be removed or loosened to rotate the engine so still not very safe during the period support is not in use. Preferred would be to support the engine from the side as Packard did on their shop stands. Here is a photo of the Packard stand. I'd bet Ross has a good safe setup so it would be good to see a photo of what he has.

To mount the long engines to my el cheapo HF stand in a method similar to the Packard way I went to a metal salvage and found a length of scrap 1/2" thick plate steel about 4" wide. Length was about 4' which was cut to fit the length of engine plus a couple of inches left over on each end. Bought some concrete foundation anchor J bolts at the hardware store and drilled the plate so those could snugly fit on each end of engine. You can get those bolts long enough to reach the valve side and lock in the cavity although the J portion did have to be trimmed a bit for a snug fit. A friend welded a piece of pipe to fit the HF bore on the plate so the engine could be rotated in the stand. He also welded a bit of metal to the bottom of the plate to reach a couple of the bolt holes on the low side of block. It worked rather well for the engines I did. I'd post a photo but it was given to a friend for his engine and now resides in another state.

Attach file:

(31.90 KB)

(31.90 KB)

To mount the long engines to my el cheapo HF stand in a method similar to the Packard way I went to a metal salvage and found a length of scrap 1/2" thick plate steel about 4" wide. Length was about 4' which was cut to fit the length of engine plus a couple of inches left over on each end. Bought some concrete foundation anchor J bolts at the hardware store and drilled the plate so those could snugly fit on each end of engine. You can get those bolts long enough to reach the valve side and lock in the cavity although the J portion did have to be trimmed a bit for a snug fit. A friend welded a piece of pipe to fit the HF bore on the plate so the engine could be rotated in the stand. He also welded a bit of metal to the bottom of the plate to reach a couple of the bolt holes on the low side of block. It worked rather well for the engines I did. I'd post a photo but it was given to a friend for his engine and now resides in another state.

Attach file:

(31.90 KB)

(31.90 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=167829