Re: KPack's 1954 Panama

Posted by HH56 On 2020/9/10 17:06:43

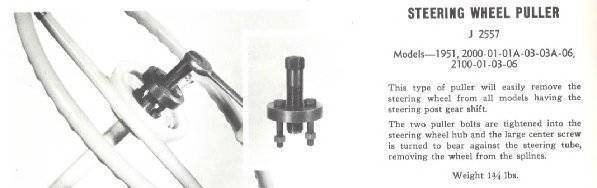

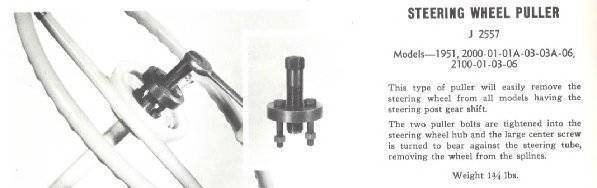

You may be able to rent something from a local parts store or the type shown is fairly inexpensive at Amazon or ebay. On the inexpensive puller you may also need to buy a couple more screws to fit the threaded holes in the wheel hub. You could make something similar to the factory puller using a flat but thick piece of metal drilled for the hub screws and threaded for the center pull bolt.

Definitely get the correct type puller or you risk damage to the end of the shaft or the threads which will make replacing the wheel very difficult. To remove the wheel, use your palm to push down on the horn emblem and then twist slightly CCW to release it. There is a rubber cushion under the emblem which if deteriorated and became sticky can cause issues. Once the emblem is off remove the 3 screws holding the horn ring assy to expose the nut. Disconnect the horn wire from the inline connector at the end of the steering box and tie a long string to it. Pull the contact, wire and string up out of the shaft. Cut off the string but use grease or something on the inside of the shaft so you can tuck the string down and out of the way but not have it fall back down the shaft. Before going farther, measure the gap between the wheel and the shroud so you get the wheel back to near the same distance so the pins on the hub can reach and release the turn signal switch cancel hooks. Normally the gap is about 1/16 to 1/8". Remove the nut or just loosen it several turns to get a bit of space for the wheel to slide up off the splines a bit. Unless you have the correct puller with a wide support that lays over and protects the threads I would suggest you try and leave the nut on the end of the shaft so the threads do not get damaged. If nut has to come off for enough room for the puller place something over the shaft so the end does not mushroom or threads collapse. Once the splines break free or turning the puller bolt has eased then you can remove the nut. Just replace the wheel in the reverse order using the string to pull the wire back down. You may need to wrap a thin piece of tape over the string and wire end to make a smoothed taper so the wire end will start thru and more easily pass thru a narrow channel at the box.

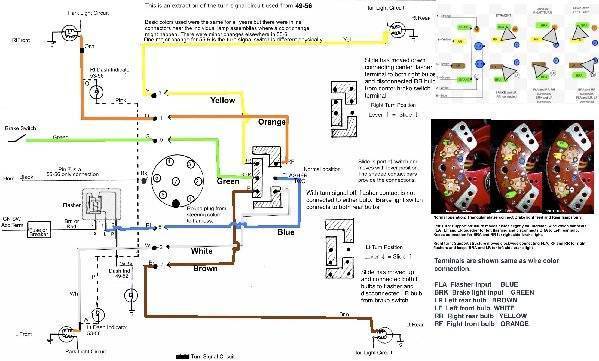

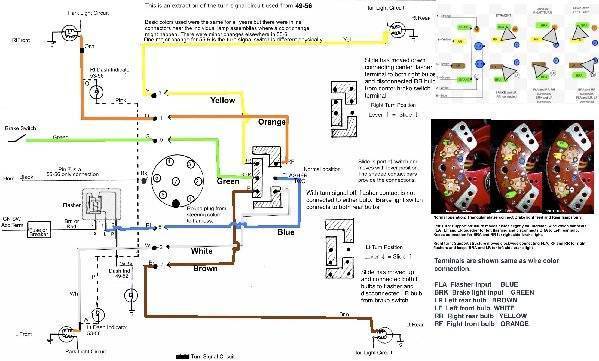

On the turn signals, here is an extraction showing the 51-4 switch and the overall circuit. Switch physically changed in 55-6 but electrically, it is the same. The sand could have done a job on the switch as could old age warping of a phenolic support board causing a contact to not be in line with the others and make a connection. Corrosion buildup on the contacts from just sitting could also be the issue.

Attach file:

(56.64 KB)

(56.64 KB)

(39.70 KB)

(39.70 KB)

(236.29 KB)

(236.29 KB)

Definitely get the correct type puller or you risk damage to the end of the shaft or the threads which will make replacing the wheel very difficult. To remove the wheel, use your palm to push down on the horn emblem and then twist slightly CCW to release it. There is a rubber cushion under the emblem which if deteriorated and became sticky can cause issues. Once the emblem is off remove the 3 screws holding the horn ring assy to expose the nut. Disconnect the horn wire from the inline connector at the end of the steering box and tie a long string to it. Pull the contact, wire and string up out of the shaft. Cut off the string but use grease or something on the inside of the shaft so you can tuck the string down and out of the way but not have it fall back down the shaft. Before going farther, measure the gap between the wheel and the shroud so you get the wheel back to near the same distance so the pins on the hub can reach and release the turn signal switch cancel hooks. Normally the gap is about 1/16 to 1/8". Remove the nut or just loosen it several turns to get a bit of space for the wheel to slide up off the splines a bit. Unless you have the correct puller with a wide support that lays over and protects the threads I would suggest you try and leave the nut on the end of the shaft so the threads do not get damaged. If nut has to come off for enough room for the puller place something over the shaft so the end does not mushroom or threads collapse. Once the splines break free or turning the puller bolt has eased then you can remove the nut. Just replace the wheel in the reverse order using the string to pull the wire back down. You may need to wrap a thin piece of tape over the string and wire end to make a smoothed taper so the wire end will start thru and more easily pass thru a narrow channel at the box.

On the turn signals, here is an extraction showing the 51-4 switch and the overall circuit. Switch physically changed in 55-6 but electrically, it is the same. The sand could have done a job on the switch as could old age warping of a phenolic support board causing a contact to not be in line with the others and make a connection. Corrosion buildup on the contacts from just sitting could also be the issue.

Attach file:

(56.64 KB)

(56.64 KB)

(39.70 KB)

(39.70 KB)

(236.29 KB)

(236.29 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=226439