Re: MikeSC

Posted by HH56 On 2023/7/13 13:06:18

As long as there are no modern solid state replacement devices such as a radio vibrator or torsion level switch or a modern permanent magnet starter or window motor installed then nothing else on a Clipper will be damaged or really care about the polarity swap. There is still a question about what exactly is different in voltage regulators to be labeled positive or negative or universal but other than a possibly shortened life, as long as the car is charging then it is working. For best spark efficiency the coil should match the battery polarity so with a negative ground, the negative terminal on the coil should be connected to the distributor.

The gas gauge reading backwards has nothing to do with polarity. All the gauge has inside is a heating coil to warm or cool a bimetal strip. To read backwards, I suspect there is an issue with the sender. Possibly the original sender failed and an aftermarket universal sender was installed incorrectly or a GM sender with reversed resistance was tried. What you need has a resistance of approximately 73 ohms at empty and 10 ohms at full. Repro senders are available from our vendors or some Ford senders of the mid to late 50s are also compatible. With the Ford items you need to get one with the correct arm length.

To test the sender, if you disconnect the sender wire at the tank end going to the gauge, the gauge should read empty. Touch the wire to ground and gauge immediately starts going to full. Do not leave the wire connected to ground longer than it takes to verify the gauge will go to full. To test the sender itself will require an ohmmeter set to the 100 ohm scale. One lead on ground, the other to the disconnected wire from the sender and you should get a reading. With the sender still in the tank there will be only one value depending on fuel level so sender needs to be removed and arm moved thru its range for a complete test.

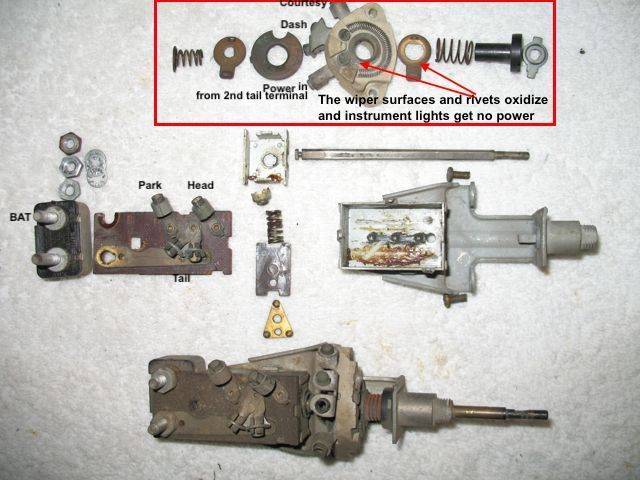

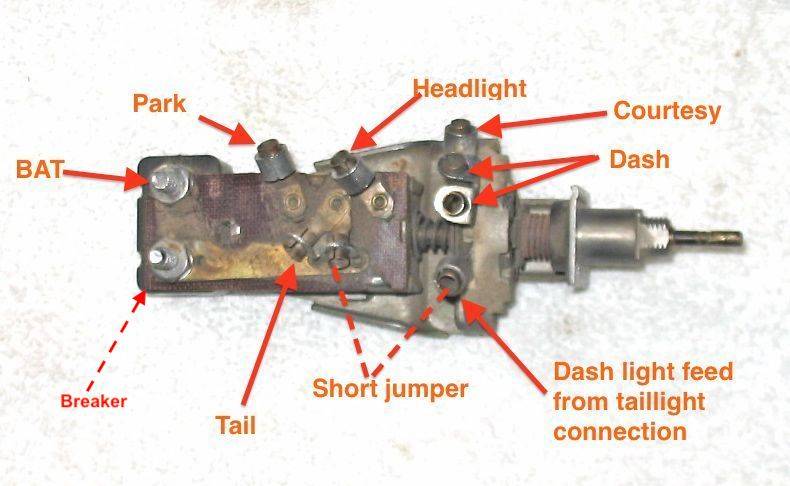

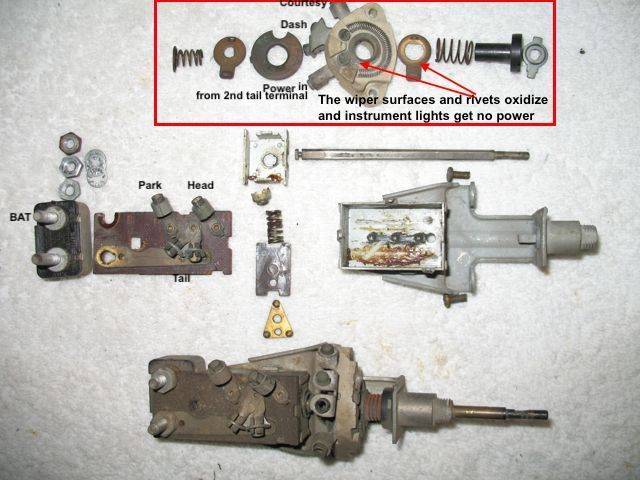

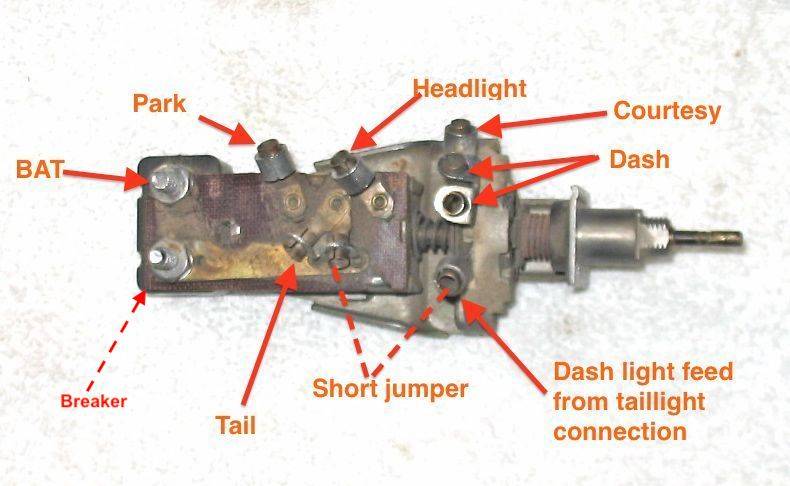

The cluster lights not working are a well known issue and generally caused by an oxidized or dirty wiper or terminal contact in the headlight switch rheostat section. Sometimes cleaning with contact cleaner or a tiny dab of valve grinding compound on the wiper surface followed by a rapid back and forth movement and then a thorough rinse will restore contact but often the cleaning fix is short lived and other options need to be explored. The switch rheostat section is riveted together and does not come apart easily so any cleaning needs to be done with the switch intact.

Attach file:

51-6 Headlight switch Exploded view.jpg (55.02 KB)

51-6 Headlight switch Exploded view.jpg (55.02 KB)

Headlight switch terminals.jpg (50.41 KB)

Headlight switch terminals.jpg (50.41 KB)

The gas gauge reading backwards has nothing to do with polarity. All the gauge has inside is a heating coil to warm or cool a bimetal strip. To read backwards, I suspect there is an issue with the sender. Possibly the original sender failed and an aftermarket universal sender was installed incorrectly or a GM sender with reversed resistance was tried. What you need has a resistance of approximately 73 ohms at empty and 10 ohms at full. Repro senders are available from our vendors or some Ford senders of the mid to late 50s are also compatible. With the Ford items you need to get one with the correct arm length.

To test the sender, if you disconnect the sender wire at the tank end going to the gauge, the gauge should read empty. Touch the wire to ground and gauge immediately starts going to full. Do not leave the wire connected to ground longer than it takes to verify the gauge will go to full. To test the sender itself will require an ohmmeter set to the 100 ohm scale. One lead on ground, the other to the disconnected wire from the sender and you should get a reading. With the sender still in the tank there will be only one value depending on fuel level so sender needs to be removed and arm moved thru its range for a complete test.

The cluster lights not working are a well known issue and generally caused by an oxidized or dirty wiper or terminal contact in the headlight switch rheostat section. Sometimes cleaning with contact cleaner or a tiny dab of valve grinding compound on the wiper surface followed by a rapid back and forth movement and then a thorough rinse will restore contact but often the cleaning fix is short lived and other options need to be explored. The switch rheostat section is riveted together and does not come apart easily so any cleaning needs to be done with the switch intact.

Attach file:

51-6 Headlight switch Exploded view.jpg (55.02 KB)

51-6 Headlight switch Exploded view.jpg (55.02 KB)

Headlight switch terminals.jpg (50.41 KB)

Headlight switch terminals.jpg (50.41 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=259187