Re: Beating a Dead horse - 6v AC

Posted by HH56 On 2010/1/10 14:46:30

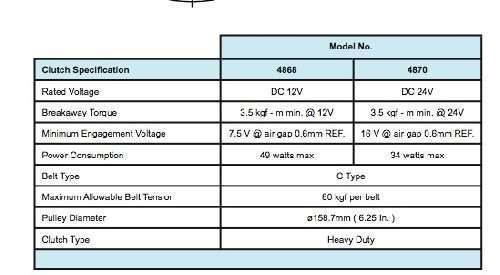

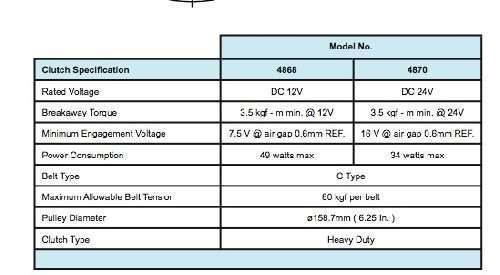

You've nailed the options since nothing 6v is available with a clutch unless you can find an old one--and then any parts to repair if needed probably won't be easily found. A few guys on other make forums have tried the decreased gap and apparently with mixed success. The Sanden FLX series (chart below) says minimum 7.5v needed so MIGHT possibly work on 6 if you can reduce that gap even further. Not sure how much current draw at 6v though or if heat due to wrong voltage and slippage or improper engagement would be an issue. If you are going to go clutchless as Packard did thru 54 then might be able to find a pulley for the shaft of the GM A6 or Sanden and replace the clutch entirely---HOWEVER--.

Temp control to keep evaporator from freezing will be the prime issue with the always on route. Secondary issue will be the increased load of compressor always moving refrigerant when trying to start engine. Postwar Packard (& others of that era) used hot gas bypass either via electrically adjusted thermostat & solenoid valve thru 54 and then a clutch for off but a self contained fixed temp modulating valve set above freezing for temp in 55-6. Those methods regulated temp and also enabled compressor to short circuit the freon to reduce load. To do that today would require some engineering, parts, and worse, is a hard system to diagnose issues should they arise. In the 50s, 60s & up thru gas crisis GM type reheat systems most used, the suction throttling and then later POA & other assorted named methods of restricting refrigerant flow to starve the evaporator might be adaptable for the freezing but still had clutches for the load. Even parts for those alphabet named systems are getting thin to the point some AC places now offer dummy valves to maintain the plumbing connections as replacements when those need work & suggest converting to cycling clutch like modern cars use. Guess what I've taken the long way to say is I don't see anyway around a clutch today.

The 6v motor turning a compressor I don't know if it has ever been tried but as you mentioned, it would take a pretty good sized motor and pretty heavy current.

There have been some who add a 12v battery and use another alternator to keep that charged for the AC and other 12v options while keeping the rest of car 6v.

Attach file:

(21.74 KB)

(21.74 KB)

Temp control to keep evaporator from freezing will be the prime issue with the always on route. Secondary issue will be the increased load of compressor always moving refrigerant when trying to start engine. Postwar Packard (& others of that era) used hot gas bypass either via electrically adjusted thermostat & solenoid valve thru 54 and then a clutch for off but a self contained fixed temp modulating valve set above freezing for temp in 55-6. Those methods regulated temp and also enabled compressor to short circuit the freon to reduce load. To do that today would require some engineering, parts, and worse, is a hard system to diagnose issues should they arise. In the 50s, 60s & up thru gas crisis GM type reheat systems most used, the suction throttling and then later POA & other assorted named methods of restricting refrigerant flow to starve the evaporator might be adaptable for the freezing but still had clutches for the load. Even parts for those alphabet named systems are getting thin to the point some AC places now offer dummy valves to maintain the plumbing connections as replacements when those need work & suggest converting to cycling clutch like modern cars use. Guess what I've taken the long way to say is I don't see anyway around a clutch today.

The 6v motor turning a compressor I don't know if it has ever been tried but as you mentioned, it would take a pretty good sized motor and pretty heavy current.

There have been some who add a 12v battery and use another alternator to keep that charged for the AC and other 12v options while keeping the rest of car 6v.

Attach file:

(21.74 KB)

(21.74 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=44857