Re: Rebuild started solonoid?

Posted by HH56 On 2017/5/27 16:07:18

First question I would ask is if you hear the faint click of the relay coming in or if the solenoid does shift the pinion when you try to start but the motor doesn't turn. If no action at all, possibilities are: The ground if you still have the safety circuit, the contacts on the small relay in the solenoid case that actually bring in the solenoid. If you still have your PB connected in place of the carb switch then the other common issue of a misadjusted or faulty carb switch is moot.

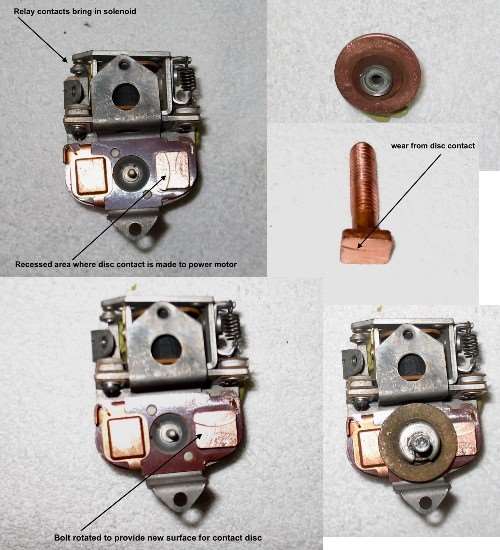

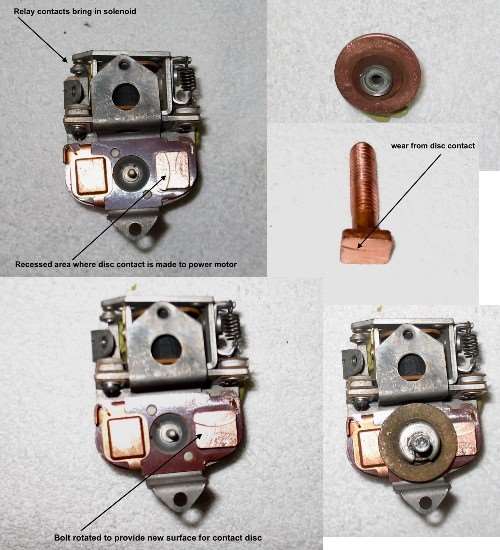

If the pinion shifts but the motor doesn't turn until you hit the solenoid then the contacts inside that connect the battery to the starter are suspect. There is a slim chance the plunger is sticking in the bore and not bringing the disc into full contact for the battery connection to be made but that would be hard to diagnose without seeing if the pinion is making full mesh with the flywheel.

On the send it out or DIY, it kind of depends on how comfortable you feel working on things like that.

It is not complicated but on that solenoid you really do need to watch the disassembly order when you remove the nuts on the copper bolts. The nuts have to come off before you can remove the cover but there are some rubber and fiber insulating grommets, washers and a sleeve that will come off too. Those insulator pieces have to be put back in the exact order to insulate the bolt connections from the cover and from some of the steel supports inside. Another thing is the rubber is old and brittle and a chunk may break off.

Along that line, parts could be an issue if you need some. I doubt the rebuild kits for that solenoid are going to be a quick find. Perhaps some of the vendors would have one but it might need to be up to a rebuilder to utilize something generic or rework a replacement component made for another solenoid.

If you do decide to tackle it, if everything seems to work except the motor doesn't turn until you hit the solenoid, the most likely place to look would be the copper disc and/or the two copper bolt heads. Note the disc on this old solenoid is fairly rough but the bolt is worse. It has a semicircular wear pattern from the disc making contact over the years. Contact surface has recessed down to the point the disc may not make good contact. Possibly the bolt could be turned 90 degrees to bring a new surface into contact or possibly a small fiber washer the thickness of the recess could be placed under the bolt head to elevate it high enough the disc can make good contact again.

Attach file:

(108.90 KB)

(108.90 KB)

If the pinion shifts but the motor doesn't turn until you hit the solenoid then the contacts inside that connect the battery to the starter are suspect. There is a slim chance the plunger is sticking in the bore and not bringing the disc into full contact for the battery connection to be made but that would be hard to diagnose without seeing if the pinion is making full mesh with the flywheel.

On the send it out or DIY, it kind of depends on how comfortable you feel working on things like that.

It is not complicated but on that solenoid you really do need to watch the disassembly order when you remove the nuts on the copper bolts. The nuts have to come off before you can remove the cover but there are some rubber and fiber insulating grommets, washers and a sleeve that will come off too. Those insulator pieces have to be put back in the exact order to insulate the bolt connections from the cover and from some of the steel supports inside. Another thing is the rubber is old and brittle and a chunk may break off.

Along that line, parts could be an issue if you need some. I doubt the rebuild kits for that solenoid are going to be a quick find. Perhaps some of the vendors would have one but it might need to be up to a rebuilder to utilize something generic or rework a replacement component made for another solenoid.

If you do decide to tackle it, if everything seems to work except the motor doesn't turn until you hit the solenoid, the most likely place to look would be the copper disc and/or the two copper bolt heads. Note the disc on this old solenoid is fairly rough but the bolt is worse. It has a semicircular wear pattern from the disc making contact over the years. Contact surface has recessed down to the point the disc may not make good contact. Possibly the bolt could be turned 90 degrees to bring a new surface into contact or possibly a small fiber washer the thickness of the recess could be placed under the bolt head to elevate it high enough the disc can make good contact again.

Attach file:

(108.90 KB)

(108.90 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=192288