Re: R-9 overdrive not engaging now.

Posted by HH56 On 2018/8/26 14:01:47

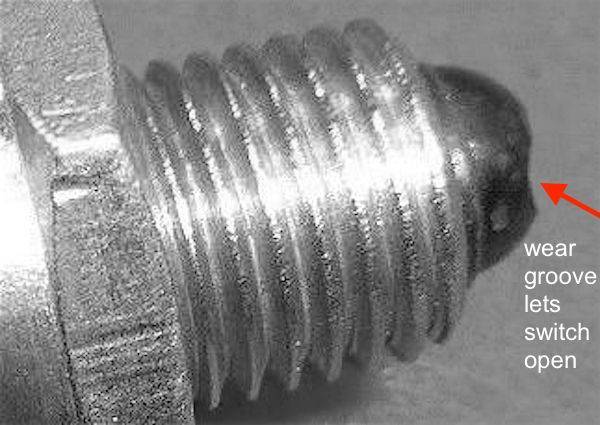

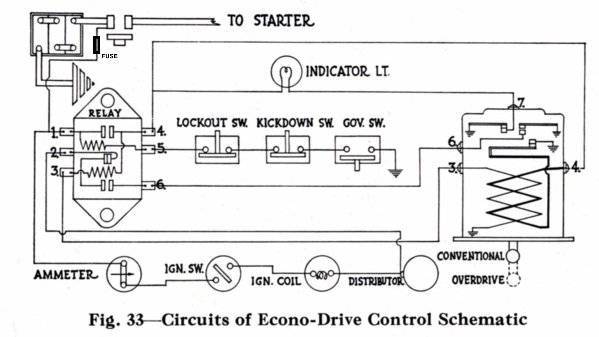

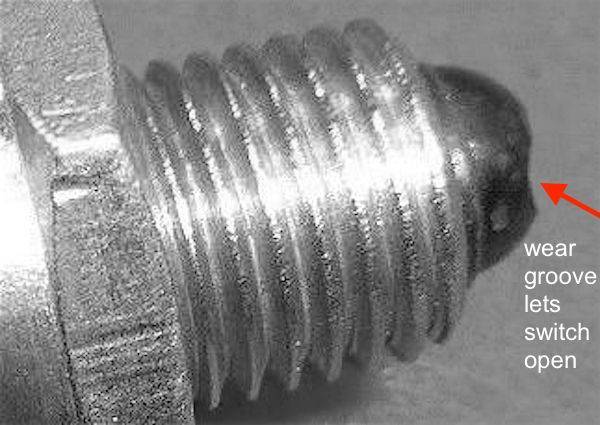

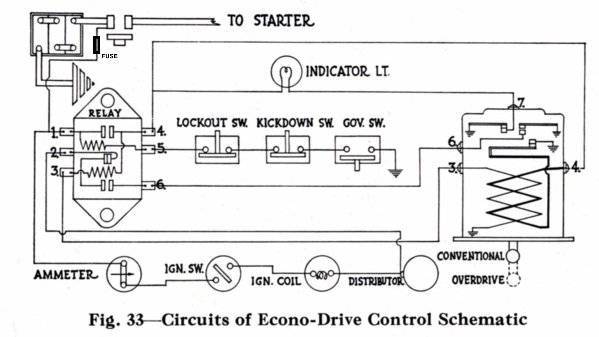

The governor providing ground thru the lockout and kickdown switches brings in the relay you probably pushed down. Can you ground terminal 5 of the relay box and have them come in? Do you hear the solenoid clunk or make any noise at the same time? If so the problem is in the governor or that series string of switches. One problem others have had develop is the lockout switch located on the end of the dash knob assy rides against the rod as the knob is moved in or out. A groove can wear in the plastic button and if it wears deep enough the lockout switch plunger doesn't move far enough to close the switch. The switch is also a known issue with intermittent OD operation as vibration can make the switch open and close if plunger is worn to the point contacts are barely closed.

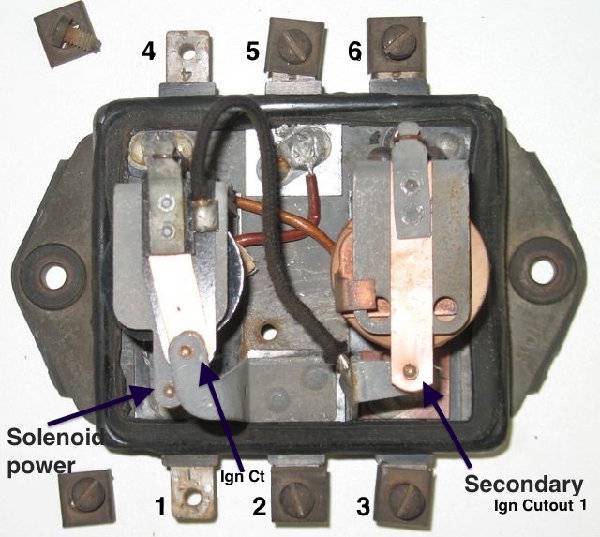

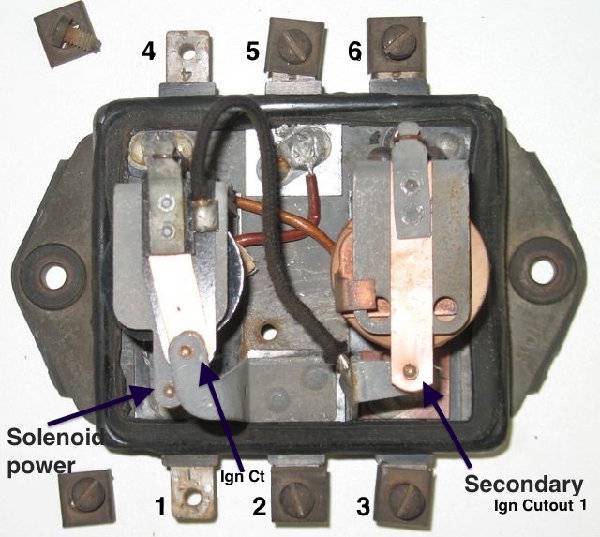

If you pushed the double contact relay located in the box between terminals 1 and 4 in the photo it should bring in the other relay as well as the solenoid. Since it apparently did bring in the second relay the box has power but did you hear any noise from the solenoid or did you notice if the light came on? The first relay feeds power to the second relay, terminal 4 of the box and out to the light and solenoid terminal 4. By going thru the coil of the second relay and then out, voltage is also delivered to terminal 3 of the solenoid. Both terminals need power for the solenoid to come in and stay in. If 4 does not have power the solenoid cannot pull in and if 3 does not have power solenoid will not stay in but will rather try to rapidly pull in and drop out making a horrific noise.

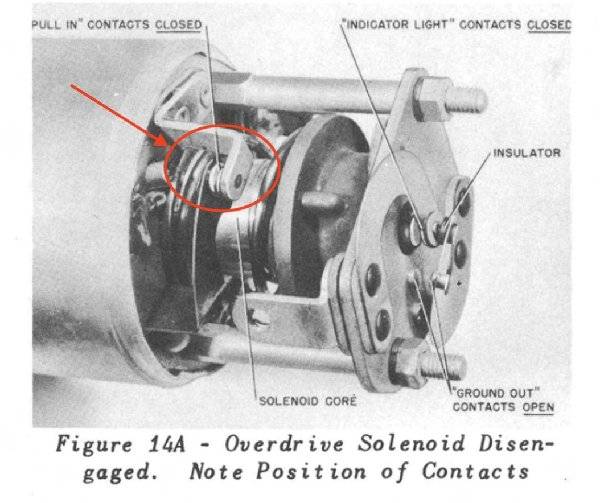

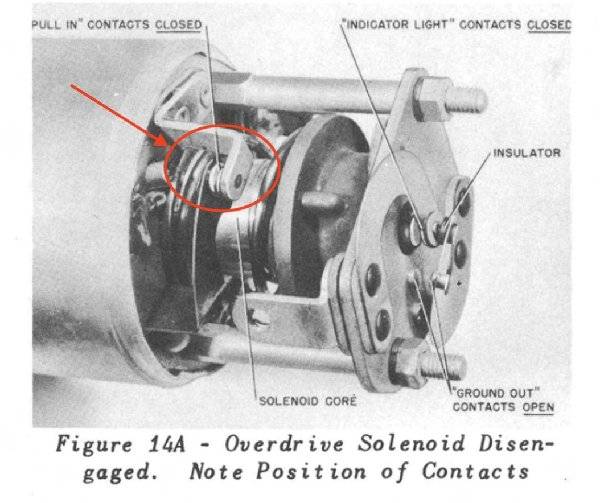

If you have power on both terminals but the solenoid does not make any noise or try to come in, assuming the pull in coil is OK there is a set of contacts inside the solenoid that could have pitted or burned so that power is not flowing thru the coil. The contacts in the solenoid were a serviceable item and do pit because of the heavy current and arc developed when they open to drop out the pull in coil as the solenoid plunger extends fully. The hold coil alone is not strong enough to bring in the solenoid on its own.

You mentioned connectors at the governor and solenoid being replaced but does your car still have the two piece loom with the original black plastic inline connectors located about 3 ft from the OD or on the X part of the frame roughly under the drivers foot area? Those connectors were known to cause problems too. Assuming there are no breaks or disconnections, if the connectors are corroded inadequate amperage or voltage to the solenoid could also be an issue.

Attach file:

(56.84 KB)

(56.84 KB)

(41.37 KB)

(41.37 KB)

(66.44 KB)

(66.44 KB)

(88.92 KB)

(88.92 KB)

If you pushed the double contact relay located in the box between terminals 1 and 4 in the photo it should bring in the other relay as well as the solenoid. Since it apparently did bring in the second relay the box has power but did you hear any noise from the solenoid or did you notice if the light came on? The first relay feeds power to the second relay, terminal 4 of the box and out to the light and solenoid terminal 4. By going thru the coil of the second relay and then out, voltage is also delivered to terminal 3 of the solenoid. Both terminals need power for the solenoid to come in and stay in. If 4 does not have power the solenoid cannot pull in and if 3 does not have power solenoid will not stay in but will rather try to rapidly pull in and drop out making a horrific noise.

If you have power on both terminals but the solenoid does not make any noise or try to come in, assuming the pull in coil is OK there is a set of contacts inside the solenoid that could have pitted or burned so that power is not flowing thru the coil. The contacts in the solenoid were a serviceable item and do pit because of the heavy current and arc developed when they open to drop out the pull in coil as the solenoid plunger extends fully. The hold coil alone is not strong enough to bring in the solenoid on its own.

You mentioned connectors at the governor and solenoid being replaced but does your car still have the two piece loom with the original black plastic inline connectors located about 3 ft from the OD or on the X part of the frame roughly under the drivers foot area? Those connectors were known to cause problems too. Assuming there are no breaks or disconnections, if the connectors are corroded inadequate amperage or voltage to the solenoid could also be an issue.

Attach file:

(56.84 KB)

(56.84 KB)

(41.37 KB)

(41.37 KB)

(66.44 KB)

(66.44 KB)

(88.92 KB)

(88.92 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=205493