Re: 1951 oil filter

Posted by HH56 On 2024/6/18 19:00:05

That is the return port and you will need to get a fitting to use it. Fitting will be 1/8 NPT pipe on the block side to a 1/4 inverted flare tube on the other. You will need to decide if a straight fitting or angled elbow will better suit where and how you are wanting to run the tubing. The tubing will need to have a flared end and a nut that threads into the fitting. Some parts stores sell fixed length 1/4" steel tubing in their brake line departments. Those come with nuts and flares already installed but lengths are limited so you might not find exactly what you need. A little extra length can be taken care of with creative bends but too short or way too long and you will need to custom make your own. One thing to be cautious of if you buy premade tubes is they are often on a rack and metric sizes can get mixed in with SAE. If you do make your own, steel tubing is a pain to flare so try to get a length of 1/4" copper nickel or Cunifer tubing instead. That is much easier to bend and flare but if you are looking for a stock appearance it is more copper in color.

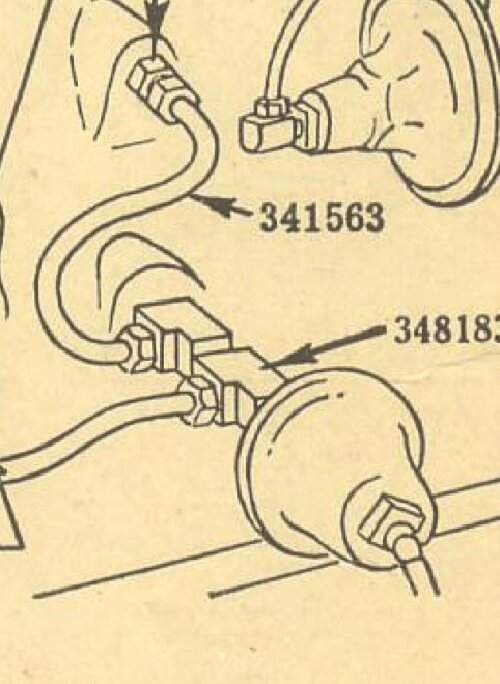

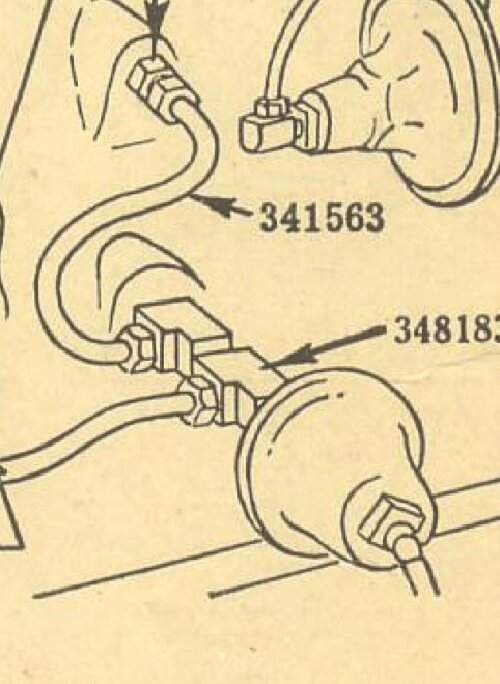

The factory 4 way block as shown in the earlier post may be hard to find. I believe Packard made their own in that specific layout or had it specifically made so won't be found as a common item. Possibly one of the used vendors or someone with a parts car will have an original. The standard modern 4 way cross with one NPT port and 3 inverted flare ports may also not be stocked at many places so can also be hard to find. At one time Max Merritt had put together a regular cross with a separate nipple that mimicked the original and worked well. You can also adapt something using the micky mouse combo of tees and close nipples as Packard did before they had the block. Those are sort of unsightly but will work. Here is an example of the tee and nipple arrangement.

To me, the canister looks postwar in shape but with the hints of orange paint it may be aftermarket or off another brand engine or from one where an owner got carried away with orange paint. Clean it a bit and look near each fitting and see if you can see an inlet or outlet stamped in the metal canister. If you find a label then plumb accordingly. Then check the center pipe when you clean out the unit and look for any very small holes drilled in the length. If you find one or two small holes then it may have a built in orifice but if the holes are numerous or fairly large then there is no restriction and you will need to add something in one of the fittings. If no in-out labels or restrictions to flow are found it will be a guess. If I were doing it then presuming the element Kev mentioned will fit, I would try for a side inlet. To me the large outer area of the element would then get the dirty oil and be less likely to get clogged than if the smaller inner diameter of the element got it all. Adding another restriction in a fitting may cut the overall flow a bit more if one is already existing but flow should still be quite adequate and better than the nothing it has had until now.

Packard wanted the flow thru the filter to be limited at roughly 10% of volume available at the engine supply port and no more than 15%. To do this solder was melted in one of the fittings and then a 5/64 diameter hole was drilled thru the solder. If your filter canister does not have any restrictions built in you will need to add something in one of your fittings. The restriction is needed because a huge flow thru the filter can lower the oil pressure particularly if the engine is high mileage or has worn bearings.

The factory 4 way block as shown in the earlier post may be hard to find. I believe Packard made their own in that specific layout or had it specifically made so won't be found as a common item. Possibly one of the used vendors or someone with a parts car will have an original. The standard modern 4 way cross with one NPT port and 3 inverted flare ports may also not be stocked at many places so can also be hard to find. At one time Max Merritt had put together a regular cross with a separate nipple that mimicked the original and worked well. You can also adapt something using the micky mouse combo of tees and close nipples as Packard did before they had the block. Those are sort of unsightly but will work. Here is an example of the tee and nipple arrangement.

To me, the canister looks postwar in shape but with the hints of orange paint it may be aftermarket or off another brand engine or from one where an owner got carried away with orange paint. Clean it a bit and look near each fitting and see if you can see an inlet or outlet stamped in the metal canister. If you find a label then plumb accordingly. Then check the center pipe when you clean out the unit and look for any very small holes drilled in the length. If you find one or two small holes then it may have a built in orifice but if the holes are numerous or fairly large then there is no restriction and you will need to add something in one of the fittings. If no in-out labels or restrictions to flow are found it will be a guess. If I were doing it then presuming the element Kev mentioned will fit, I would try for a side inlet. To me the large outer area of the element would then get the dirty oil and be less likely to get clogged than if the smaller inner diameter of the element got it all. Adding another restriction in a fitting may cut the overall flow a bit more if one is already existing but flow should still be quite adequate and better than the nothing it has had until now.

Packard wanted the flow thru the filter to be limited at roughly 10% of volume available at the engine supply port and no more than 15%. To do this solder was melted in one of the fittings and then a 5/64 diameter hole was drilled thru the solder. If your filter canister does not have any restrictions built in you will need to add something in one of your fittings. The restriction is needed because a huge flow thru the filter can lower the oil pressure particularly if the engine is high mileage or has worn bearings.

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=273038