Re: Shifter Rebuild Info Needed

Posted by HH56 On 2015/6/14 22:31:31

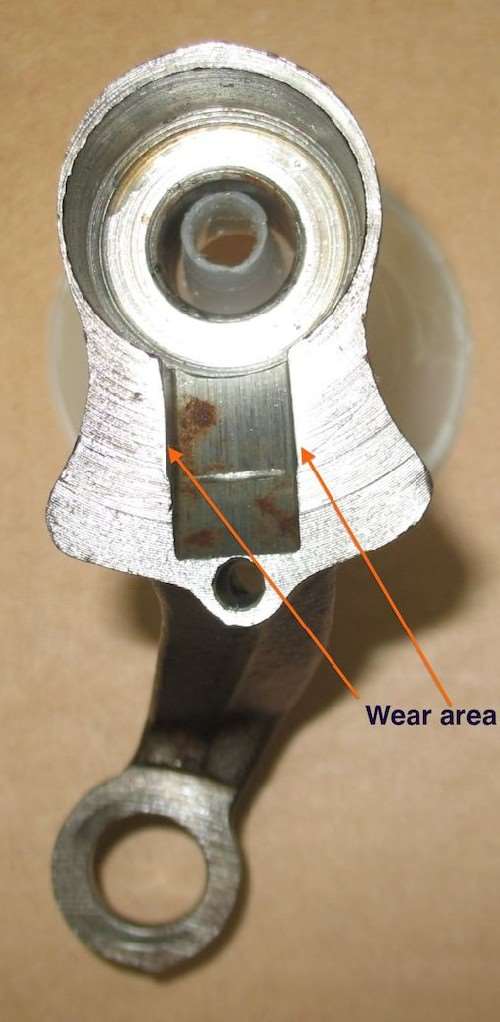

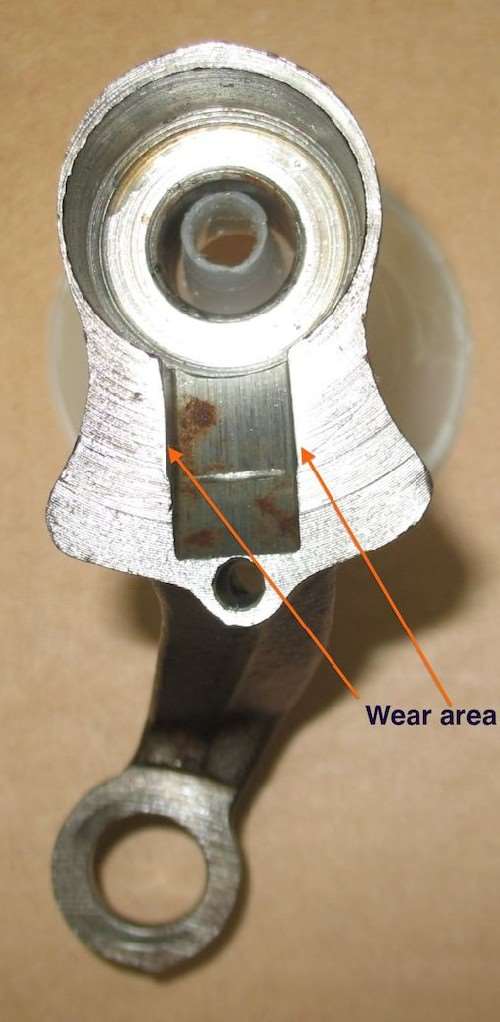

There is not a lot to rebuild as other than the bushings you've already replaced there are only a couple of places left that can wear -- the tongue on the shift lever selector and the area inside the flat portion of the shift levers where the tongue meshes to select a particular gear. The tongue normally resides in the recess in the upper 2-3 lever. When you pull the operator lever back for R or 1 the tongue moves into the recess in the lower lever. Moving the operator lever rotates the entire tube and because the tongue assy is splined to the tube it causes the lever containing the tongue to rotate and select the gear. The other lever stays stationary because of the detents in the transmission. Unless the car has really high mileage or someone was really rough in shifting I doubt you will find much wear.

I think the biggest problem you might find is lack of lubrication. There is a small oil hole in the side of the tube where oil can drip down and wet the end where one of the rubber antivibration bushings rests. It can also run out the slot where the pin connects the rod to the tongue assy and lube the lower R-1 lever. There is nothing for the upper 2-3 shift lever. Any oil the upper lever gets depends on someone spilling or purposely placing a drop or two on the tube and letting it run down between the lever and tube into the rotation space.

If the original factory lube has dried and corrosion has set in as happened on my car the upper lever can seize on the shift tube and cause grief when shifting. It will try to move when you only want the lower or R-1 lever to move. If you do nothing else, I would strongly suggest you apply a few drops of oil at the top of the upper lever and let it run down between the lever and tube. A couple more drops of oil in the hole and maybe in the space between levers should take care of everything else.

Here are some photos of a disassembled 21st series which is for all purposes identical to yours. I've marked the wear and corrosion areas. In the one photo of the tube before it was cleaned you can see the rust and corrosion on the shift tube where the upper lever had seized. It was a project getting that lever off too.

The assy is held together mostly by circlips and a cotter key. The spring pushing on the rod is fairly healthy so be aware when you disassemble things. The spring can go flying when the cotter key is removed which you have to do before you can remove the lower mounting bracket and access the rest of the parts.

Attach file:

(32.96 KB)

(32.96 KB)

(57.34 KB)

(57.34 KB)

(44.57 KB)

(44.57 KB)

I think the biggest problem you might find is lack of lubrication. There is a small oil hole in the side of the tube where oil can drip down and wet the end where one of the rubber antivibration bushings rests. It can also run out the slot where the pin connects the rod to the tongue assy and lube the lower R-1 lever. There is nothing for the upper 2-3 shift lever. Any oil the upper lever gets depends on someone spilling or purposely placing a drop or two on the tube and letting it run down between the lever and tube into the rotation space.

If the original factory lube has dried and corrosion has set in as happened on my car the upper lever can seize on the shift tube and cause grief when shifting. It will try to move when you only want the lower or R-1 lever to move. If you do nothing else, I would strongly suggest you apply a few drops of oil at the top of the upper lever and let it run down between the lever and tube. A couple more drops of oil in the hole and maybe in the space between levers should take care of everything else.

Here are some photos of a disassembled 21st series which is for all purposes identical to yours. I've marked the wear and corrosion areas. In the one photo of the tube before it was cleaned you can see the rust and corrosion on the shift tube where the upper lever had seized. It was a project getting that lever off too.

The assy is held together mostly by circlips and a cotter key. The spring pushing on the rod is fairly healthy so be aware when you disassemble things. The spring can go flying when the cotter key is removed which you have to do before you can remove the lower mounting bracket and access the rest of the parts.

Attach file:

(32.96 KB)

(32.96 KB)

(57.34 KB)

(57.34 KB)

(44.57 KB)

(44.57 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=163066