Re: 51 Clipper Backing plate gasket

Posted by HH56 On 2021/3/25 11:06:38

You can make the gaskets as they are nothing special and fairly easy to cut but Max Merritt and probably Kanter might have them as a gasket only set. I know Max has complete axle kits with new seals, gaskets and bearings but not sure about gaskets only. You might be able to match the seals at Napa but be careful of the depth. Most of the seals cross to modern with identical ID and OD specs to the originals but I have found the depth sometimes varies. At times the modern depth is too wide and causes clearance issues with the retainer pieces.

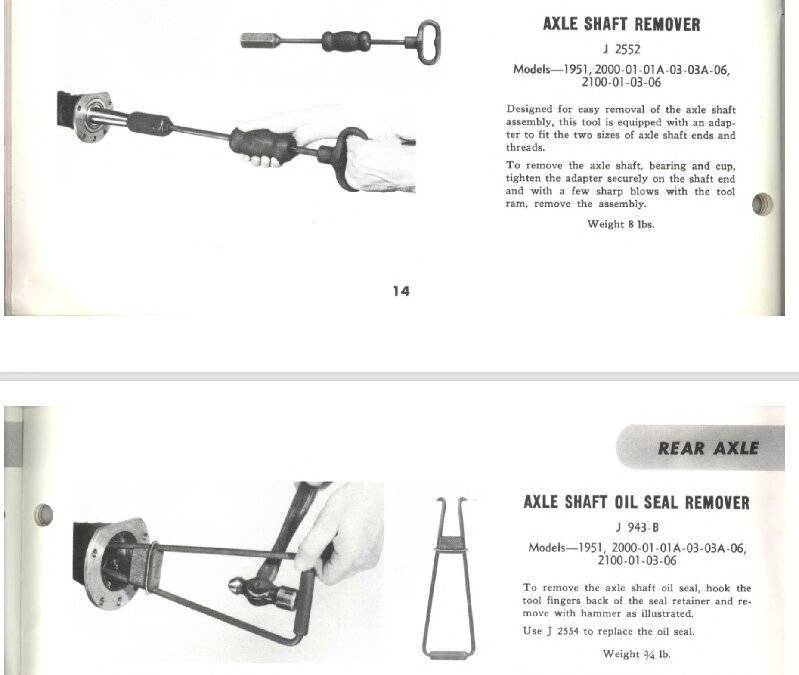

If you are going far enough to remove the axle to replace that inner seal you can perform routine maintenance by doing a lube and check of the bearings at the same time. Suggest you read thru the rear axle section on removing the axle and packing the bearings. Also take heed of the caution not to beat on the ends of the axle when using certain types of drum pullers.

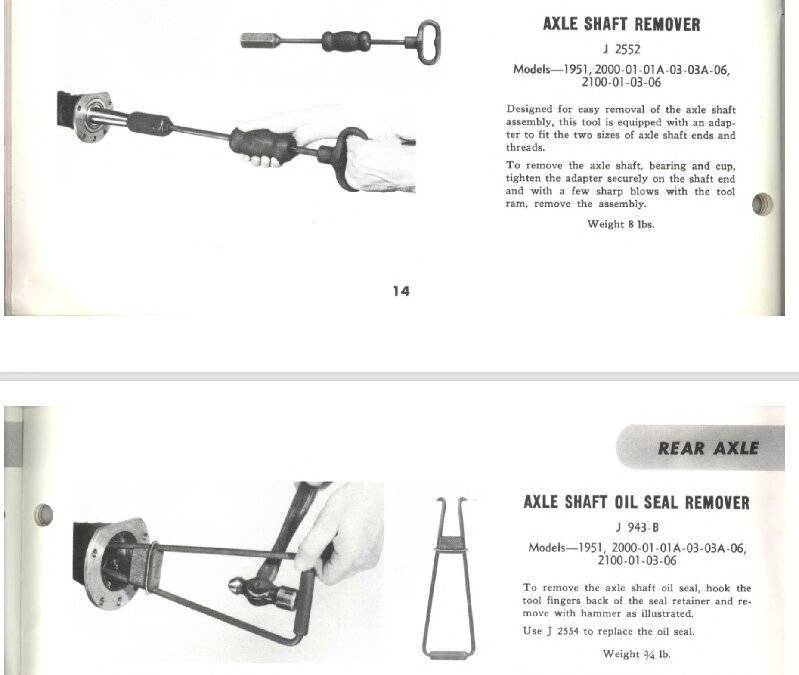

Sometimes the axle and seal will come out without out much effort but if you need a puller tool such as Packard used, a workable version can be fabricated with a common body shop slide hammer. For the axle use a coupling nut sized to fit the threads on the axle and a hex head bolt that will screw into the other end of the nut. Drill and tap the head of the bolt to fit the attachment end of the slide hammer. For the tool used to grab the seal it is a bit more work as you need to bend the ends of some flat stock to form something that can reach behind the seal to pull it out. You can either make the other end so it can attach to the slide hammer or wide to use a hammer like the original tool. It also might need something in the middle to keep the ends spread apart similar to the original tool. The axle end play checking tool has been mentioned in other posts and a search should find those posts and photos of the home made version.

It is important to keep the axle shaft from scraping over the new seal when sliding it back into the housing. That can be assisted by making a lever arrangement using the same coupling nut on the axle and a length of all thread instead of the bolt. I found the connection to the slide hammer was too weak to use for the lever so allthread was used instead. Thread the nut and allthread back on the shaft and use the other end of the allthread as a control to lift or hold the shaft up so it does not scrape the seal.

Attach file:

tool.jpg (147.57 KB)

tool.jpg (147.57 KB)

If you are going far enough to remove the axle to replace that inner seal you can perform routine maintenance by doing a lube and check of the bearings at the same time. Suggest you read thru the rear axle section on removing the axle and packing the bearings. Also take heed of the caution not to beat on the ends of the axle when using certain types of drum pullers.

Sometimes the axle and seal will come out without out much effort but if you need a puller tool such as Packard used, a workable version can be fabricated with a common body shop slide hammer. For the axle use a coupling nut sized to fit the threads on the axle and a hex head bolt that will screw into the other end of the nut. Drill and tap the head of the bolt to fit the attachment end of the slide hammer. For the tool used to grab the seal it is a bit more work as you need to bend the ends of some flat stock to form something that can reach behind the seal to pull it out. You can either make the other end so it can attach to the slide hammer or wide to use a hammer like the original tool. It also might need something in the middle to keep the ends spread apart similar to the original tool. The axle end play checking tool has been mentioned in other posts and a search should find those posts and photos of the home made version.

It is important to keep the axle shaft from scraping over the new seal when sliding it back into the housing. That can be assisted by making a lever arrangement using the same coupling nut on the axle and a length of all thread instead of the bolt. I found the connection to the slide hammer was too weak to use for the lever so allthread was used instead. Thread the nut and allthread back on the shaft and use the other end of the allthread as a control to lift or hold the shaft up so it does not scrape the seal.

Attach file:

tool.jpg (147.57 KB)

tool.jpg (147.57 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=231693