Re: 53 convertible hydraulic pump

Posted by HH56 On 2012/4/5 22:23:46

Schematics probably not much help but basically all switches are connected to pump and battery in common. All will run the pump but each window solenoid valve is individual. That prevents the windows from closing when pump pressure is working the top. All the switches are spring loaded and are off in the center position. That is the only control -- the spring returning the switch to center off. Windows are a special type switch though. Do they all feel good--no catching and with a solid spring feel in both directions? If power seat, that one too. If nothing obvious with windows or seat then how about the top switch? It is just an ordinary switch -- on when pushed or pulled but does run the pump at either command so is the rod returning to center?. If you removed it from the valve during the plumbing is it back on correctly? How many wires to the switch -- if two -- one on each terminal then unless an old loom & possibly shorted not the issue. If 4 wires with 2 on each terminal and they got mixed up or shorted, that would cause the pump to run continuously.

The special window and seat switches work by energizing both the pump and solenoid valve when in the up direction and just the valve in the down with spring tension and gravity opening the window. Again, if you still have the old wires and insulation cracked when you removed the door panels, a short between the bat and pump wires at any switch could also make the pump run. If everything mentioned looks good, Then it's a matter of disconnecting things one at a time to see what stops the pump.

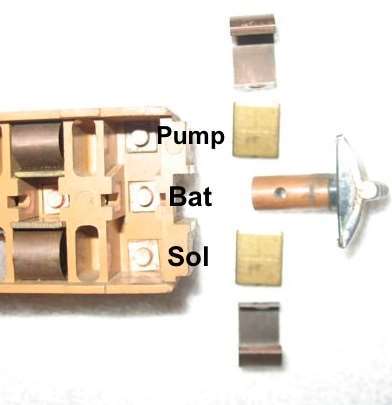

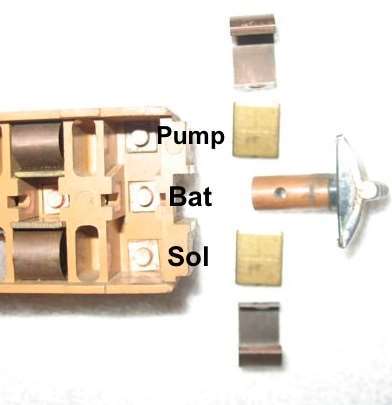

If it turns out to be a window switch, a brief description of switch operation might help. Referring to the picture, the stem of button is the actual contact to the two metal plates. The curved pieces are the springs and also part of the contact. Note the way the brass plates are mounted. You can see the supports molded into the base. The one on the solenoid side is straight vertical and the one on the pump side is angled. That is the way pump is only energized going up. The button stem is hollow at the bottom and surrounds the center BAT contact. It is held by a non conducting piece of phenolic rod. When in the up direction, the stem pivots and connects the center BAT button to the brass plates--pump side on top and solenoid side at bottom so both are energized. Pushing switch down, the stem pivots opposite direction and connects the center BAT to the solenoid side at the top. Because of the angled mount it can't touch that pump plate at the bottom so pump does not run.

Attach file:

(13.71 KB)

(13.71 KB)

The special window and seat switches work by energizing both the pump and solenoid valve when in the up direction and just the valve in the down with spring tension and gravity opening the window. Again, if you still have the old wires and insulation cracked when you removed the door panels, a short between the bat and pump wires at any switch could also make the pump run. If everything mentioned looks good, Then it's a matter of disconnecting things one at a time to see what stops the pump.

If it turns out to be a window switch, a brief description of switch operation might help. Referring to the picture, the stem of button is the actual contact to the two metal plates. The curved pieces are the springs and also part of the contact. Note the way the brass plates are mounted. You can see the supports molded into the base. The one on the solenoid side is straight vertical and the one on the pump side is angled. That is the way pump is only energized going up. The button stem is hollow at the bottom and surrounds the center BAT contact. It is held by a non conducting piece of phenolic rod. When in the up direction, the stem pivots and connects the center BAT button to the brass plates--pump side on top and solenoid side at bottom so both are energized. Pushing switch down, the stem pivots opposite direction and connects the center BAT to the solenoid side at the top. Because of the angled mount it can't touch that pump plate at the bottom so pump does not run.

Attach file:

(13.71 KB)

(13.71 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=98403