relocating pushbutton actuator

Posted by Randy Berger On 2007/6/23 23:59:43

Mr Pushbutton may have several comments after reading this. Those of us who have had to remove or work on Packard's 1956 pushbutton actuator have wondered why it should be so difficult? I have examined the tranny and actuator with the idea of moving it forward approximately six inches. This would allow room to remove it, if needed, simply and quickly.

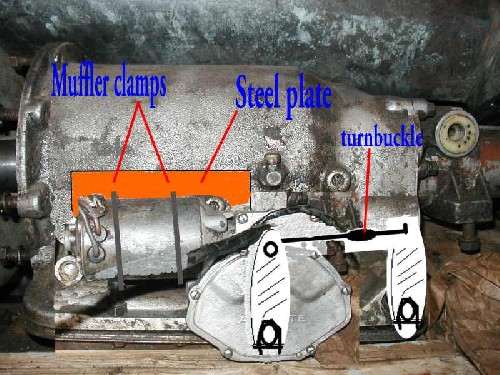

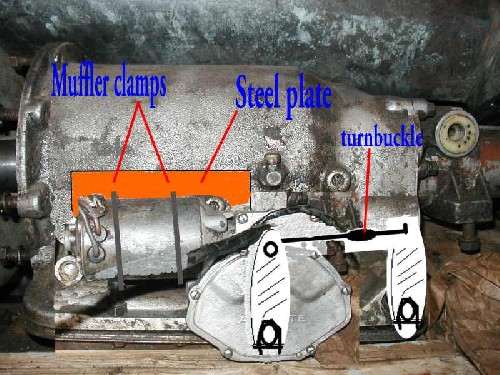

By removing the spacer that the bracket is bolted to, we uncover a 1/2-20 threaded hole. There is another recessed 1/2-20 hole directly in a vertical line to the first one. This allows a 1/8 inch piece of plate steel to be bolted to the tranny. The actuator motor can then be positioned on the plate and holes marked for drilling. The diameter of the actuator motor is roughly three inches. Two three inch muffler clamps can then be mounted on the 1/8 inch plate and the actuator motor can be secured to the plate. A shaft equal to the diameter of the shift shaft can be installed in the actuator and held securely by the set screw which normally secures to the tranny shaft. A short lever, much like those used in floor shift conversions can then be attached to both shafts and then joined by a short rod incorporating a turnbuckle. It then only requires that the transmission shaft be placed in the PARK position and the actuator motor also be positioned via the P button. Adjust the turnbuckle to allow the ends to enter the two shift levers easily and lock the turnbuckle in that position. I have attached a crude picture of the idea.

Attach file:

(75.97 KB)

(75.97 KB)

By removing the spacer that the bracket is bolted to, we uncover a 1/2-20 threaded hole. There is another recessed 1/2-20 hole directly in a vertical line to the first one. This allows a 1/8 inch piece of plate steel to be bolted to the tranny. The actuator motor can then be positioned on the plate and holes marked for drilling. The diameter of the actuator motor is roughly three inches. Two three inch muffler clamps can then be mounted on the 1/8 inch plate and the actuator motor can be secured to the plate. A shaft equal to the diameter of the shift shaft can be installed in the actuator and held securely by the set screw which normally secures to the tranny shaft. A short lever, much like those used in floor shift conversions can then be attached to both shafts and then joined by a short rod incorporating a turnbuckle. It then only requires that the transmission shaft be placed in the PARK position and the actuator motor also be positioned via the P button. Adjust the turnbuckle to allow the ends to enter the two shift levers easily and lock the turnbuckle in that position. I have attached a crude picture of the idea.

Attach file:

(75.97 KB)

(75.97 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=1450