Re: Torsion Level Operational, or not?

Posted by HH56 On 2015/3/12 22:28:43

It is going to take some work without the compensator. If the transverse bars are loose then the short bars should not be under any tension and the front bearing holding the ball arm and transverse bar end can be removed. I don't remember if the clamp holding the rubber vibration collar around the main bar will also come with the bearing plate bracket. If it does that won't affect anything.

Once the front bearing is loose that should allow the short bar to drop down a tiny bit so the plug is below the frame. Bar will still be clamped at the rear in the load arm so if it doesn't want to move down enough don't force it. With the bearing off another possibility is you may be able to loosen the clamp and slide or drive the ball arm off the short bar taking the transverse bar with it. If you do remove the arm off the bar make sure to use a dab of paint, tape or a marker on the arm and bar to make sure arm goes back on the hex at the same orientation. Downside to removing the bearing is once the bar is loose there is nothing to push against if the plug is well staked and doesn't want to budge. You might have to get creative.

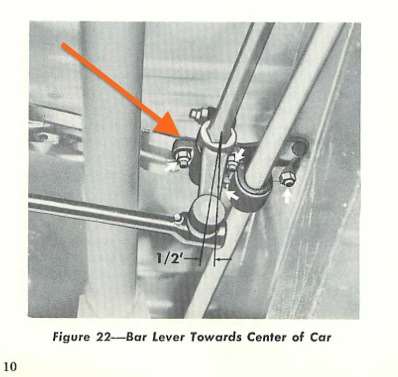

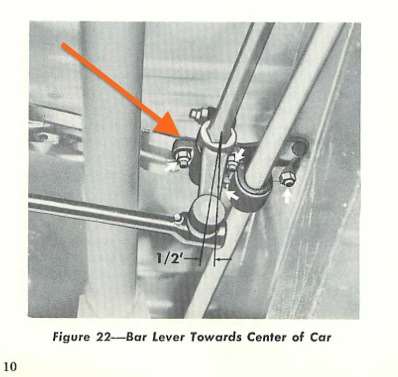

If that doesn't look like a viable option then the other thing that might work is to kind of follow the instructions in SM where they raise or lower the rear to centralize the bar in the bracket. You would have to do that by changing weight in the trunk or do what is needed in the trunk or at the rear axle to rotate and change the angle of the load arm so the short bar will rotate the ball arm toward the center.

Attach file:

(21.65 KB)

(21.65 KB)

Once the front bearing is loose that should allow the short bar to drop down a tiny bit so the plug is below the frame. Bar will still be clamped at the rear in the load arm so if it doesn't want to move down enough don't force it. With the bearing off another possibility is you may be able to loosen the clamp and slide or drive the ball arm off the short bar taking the transverse bar with it. If you do remove the arm off the bar make sure to use a dab of paint, tape or a marker on the arm and bar to make sure arm goes back on the hex at the same orientation. Downside to removing the bearing is once the bar is loose there is nothing to push against if the plug is well staked and doesn't want to budge. You might have to get creative.

If that doesn't look like a viable option then the other thing that might work is to kind of follow the instructions in SM where they raise or lower the rear to centralize the bar in the bracket. You would have to do that by changing weight in the trunk or do what is needed in the trunk or at the rear axle to rotate and change the angle of the load arm so the short bar will rotate the ball arm toward the center.

Attach file:

(21.65 KB)

(21.65 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=158906