Re: 1956 Torsion Level Question

Posted by HH56 On 2021/2/24 20:54:45

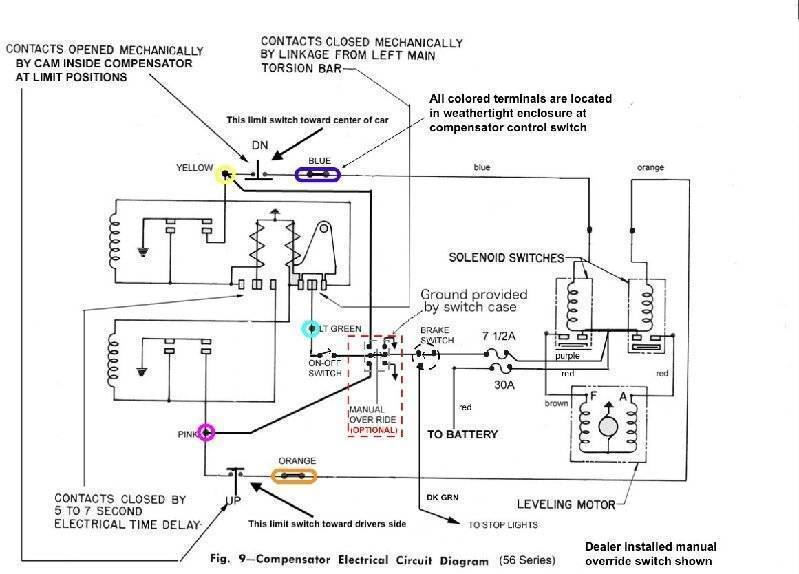

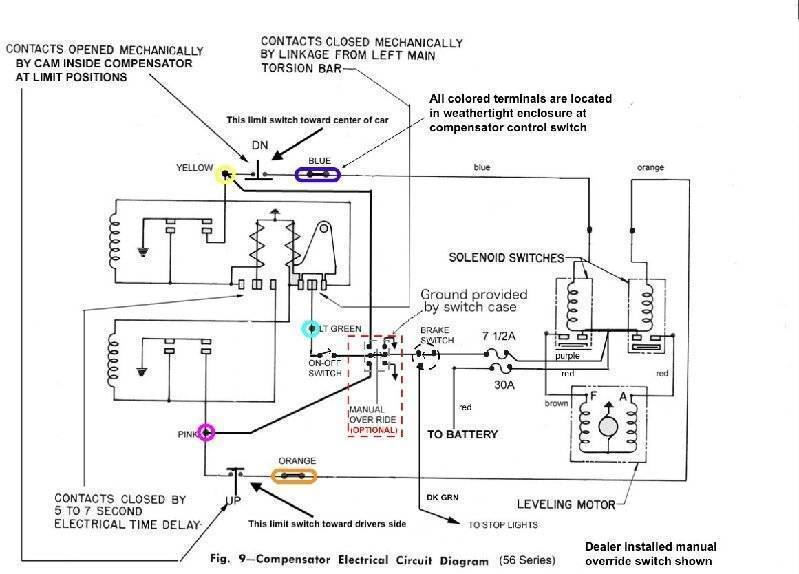

It might be a loose connection but may also be a broken wire. The limit switch with yellow and blue wires closest to the driveshaft is the down limit and usually has the wire tightly wrapped and pulled into a fairly sharp angle where it exits the switch. The wires are soldered to the terminals and the tight bend and vibration has been known to cause a wire to break.

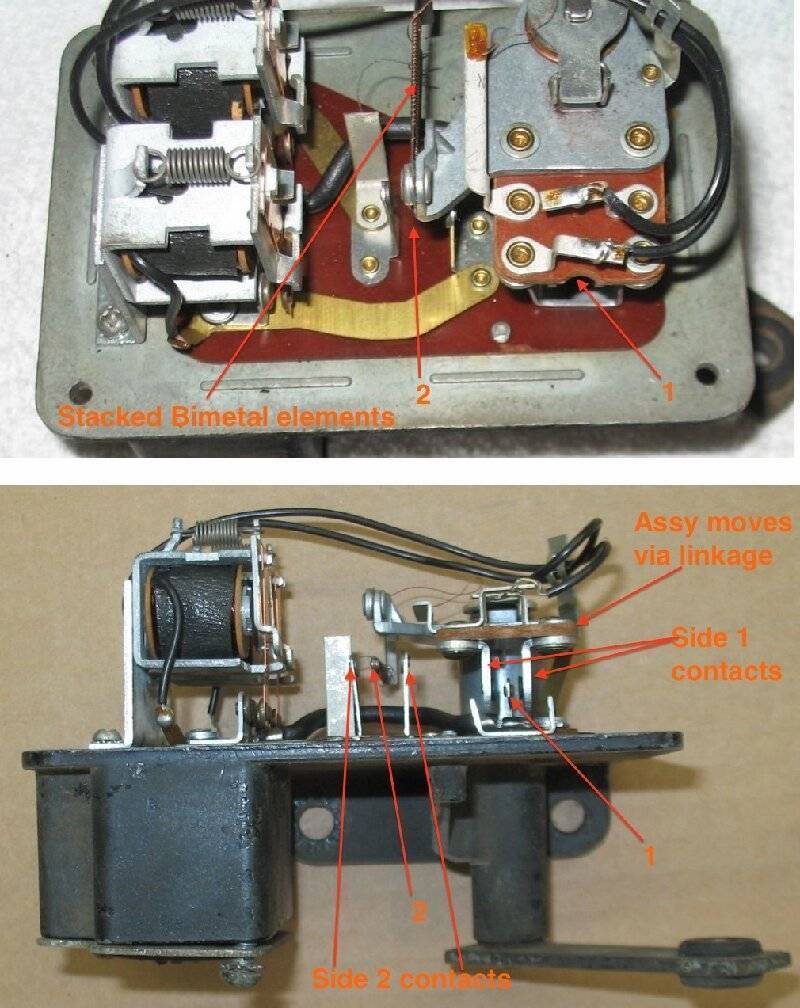

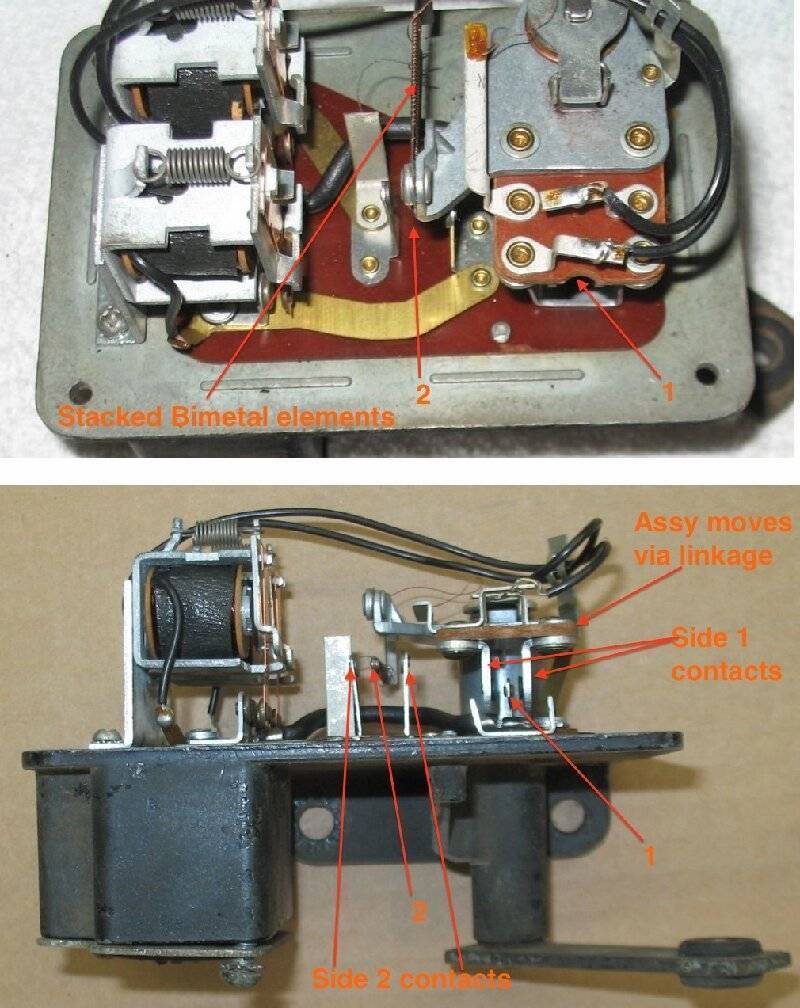

Oxidation of the contacts inside the switch is a problem with long sitting and unused switches and even NOS sitting on a shelf for decades have exhibited the problem. If yours is the original switch it could also be suspect. The time delay is controlled by a pair of heaters which bend bimetal strips to touch a fixed contact. Oxidation can require more and more pressure from the bending before there is a solid connection so it could be making and breaking contact.

The oxidation can be taken care of by carefully using a burnishing tool on the contacts. You need to remove the control switch and drill out the rivets to remove the cover to access the contacts. Be very careful not to catch and tear the extremely thin wires going to the heaters with the burnisher. The cover can be reattached with small screws and nuts.

Here is a complete schematic showing all relay and switch contacts. It also shows the optional manual up/down switch properly connected so its command output also goes thru the limit switches. The main contacts in the control switch that are operated by the linkage and start the timing are labeled 1 and bimetal contacts or those which work the relays after the time delay are those labeled 2 in the photo.

Attach file:

TL switch contacts.jpg (148.12 KB)

TL switch contacts.jpg (148.12 KB)

56 with manual TL switch.jpg (90.95 KB)

56 with manual TL switch.jpg (90.95 KB)

Oxidation of the contacts inside the switch is a problem with long sitting and unused switches and even NOS sitting on a shelf for decades have exhibited the problem. If yours is the original switch it could also be suspect. The time delay is controlled by a pair of heaters which bend bimetal strips to touch a fixed contact. Oxidation can require more and more pressure from the bending before there is a solid connection so it could be making and breaking contact.

The oxidation can be taken care of by carefully using a burnishing tool on the contacts. You need to remove the control switch and drill out the rivets to remove the cover to access the contacts. Be very careful not to catch and tear the extremely thin wires going to the heaters with the burnisher. The cover can be reattached with small screws and nuts.

Here is a complete schematic showing all relay and switch contacts. It also shows the optional manual up/down switch properly connected so its command output also goes thru the limit switches. The main contacts in the control switch that are operated by the linkage and start the timing are labeled 1 and bimetal contacts or those which work the relays after the time delay are those labeled 2 in the photo.

Attach file:

TL switch contacts.jpg (148.12 KB)

TL switch contacts.jpg (148.12 KB)

56 with manual TL switch.jpg (90.95 KB)

56 with manual TL switch.jpg (90.95 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=230723