Re: Torsion Leveling Problem on '56 Clipper

Posted by HH56 On 2015/9/19 18:32:49

Assuming all the other connections are clean and tight and limit switches are good so no intermittent signals between the control sw and solenoids and the mechanical link between the main bar and compensator switch is solid and not slipping on the bar, the only thing left that would vary the operation is the compensator switch.

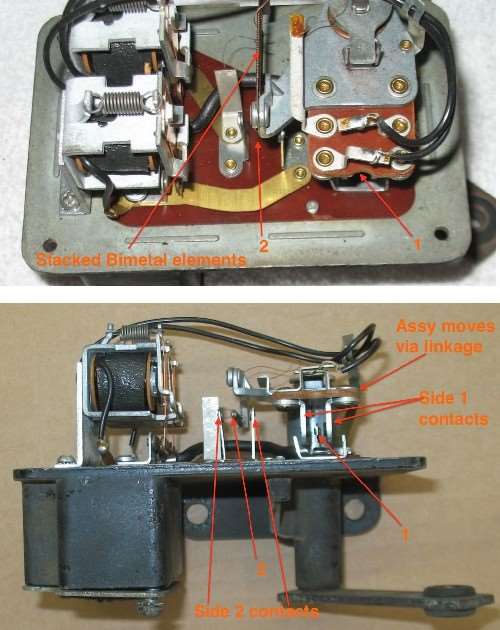

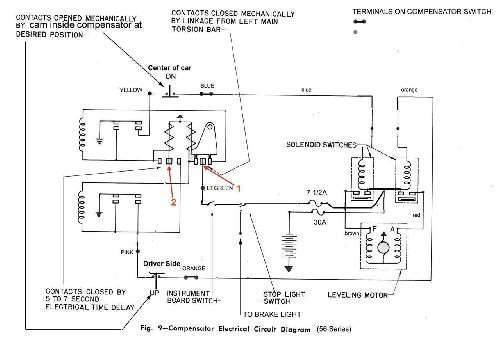

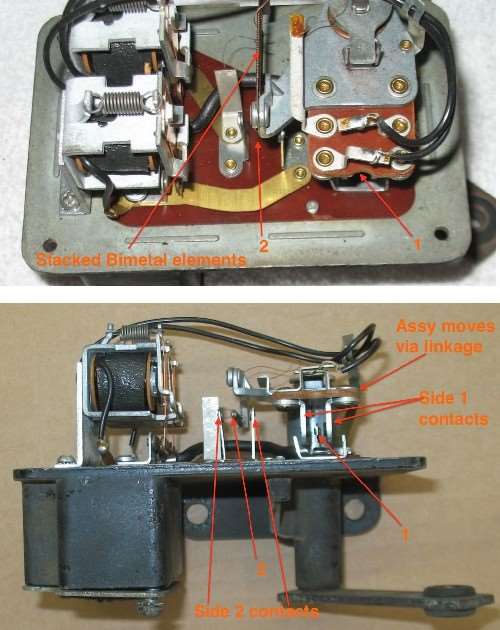

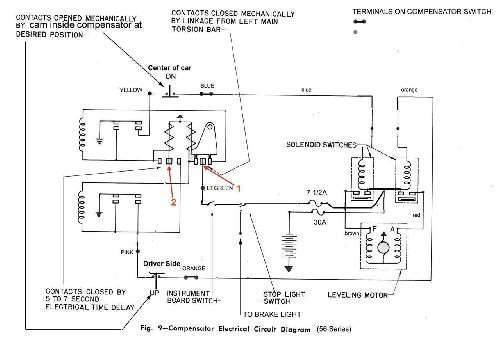

Here are a couple of photos of the original bimetal type switch and a complete 56 schematic showing the internal contacts. If you have a solid state replacement switch then that is a completely different operation in bringing in the relays.

On the original switch, when the car is out of level it moves the internal assy via the linkage. That assy is spring loaded so only rotates slightly with springs taking the extra force. The slight rotation is enough to ensure the center contact at 1 touches one of its two side contacts. Depending on which contact is made that starts heating one of two heating elements wrapped around a U shaped bimetal strip. The elements are separate and on different legs of the U one above the other.

Heating one element causes it to bend the bimetal one direction and if the other contact is made the other element heats to bend the opposite direction. The bending accounts for the approx 6 to 7 seconds delay and when it has bent far enough the end of the bimetal at 2 touches one of its side contacts and brings in a relay to energize a solenoid and start the motor.

As the car levels, the linkage also moves the rotating assy in the control switch. Because of the spring loading the car can move a considerable amount but when level is near the springs are no longer taking the force so the assy starts to rotate again. When level is reached the center contact at 1 breaks the connection to the side contact and relay drops out the solenoid stopping the motor.

If it is taking a long time it could be the ground to the control switch is poor, the voltage on the light green wire is low or one of the contacts at 1 inside the switch is oxidized so the heaters are not consistently getting enough voltage to heat the element. If that mechanical part is OK it is possible the element is not making a good solid connection at 2 to bring in a relay. If you have a solid state reworked switch then that is a completely different operation and I would surmise something has happened to the electronics.

Attach file:

(120.93 KB)

(120.93 KB)

(77.33 KB)

(77.33 KB)

Here are a couple of photos of the original bimetal type switch and a complete 56 schematic showing the internal contacts. If you have a solid state replacement switch then that is a completely different operation in bringing in the relays.

On the original switch, when the car is out of level it moves the internal assy via the linkage. That assy is spring loaded so only rotates slightly with springs taking the extra force. The slight rotation is enough to ensure the center contact at 1 touches one of its two side contacts. Depending on which contact is made that starts heating one of two heating elements wrapped around a U shaped bimetal strip. The elements are separate and on different legs of the U one above the other.

Heating one element causes it to bend the bimetal one direction and if the other contact is made the other element heats to bend the opposite direction. The bending accounts for the approx 6 to 7 seconds delay and when it has bent far enough the end of the bimetal at 2 touches one of its side contacts and brings in a relay to energize a solenoid and start the motor.

As the car levels, the linkage also moves the rotating assy in the control switch. Because of the spring loading the car can move a considerable amount but when level is near the springs are no longer taking the force so the assy starts to rotate again. When level is reached the center contact at 1 breaks the connection to the side contact and relay drops out the solenoid stopping the motor.

If it is taking a long time it could be the ground to the control switch is poor, the voltage on the light green wire is low or one of the contacts at 1 inside the switch is oxidized so the heaters are not consistently getting enough voltage to heat the element. If that mechanical part is OK it is possible the element is not making a good solid connection at 2 to bring in a relay. If you have a solid state reworked switch then that is a completely different operation and I would surmise something has happened to the electronics.

Attach file:

(120.93 KB)

(120.93 KB)

(77.33 KB)

(77.33 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=167014