Re: Transmission Swap

Posted by HH56 On 2017/4/17 12:29:52

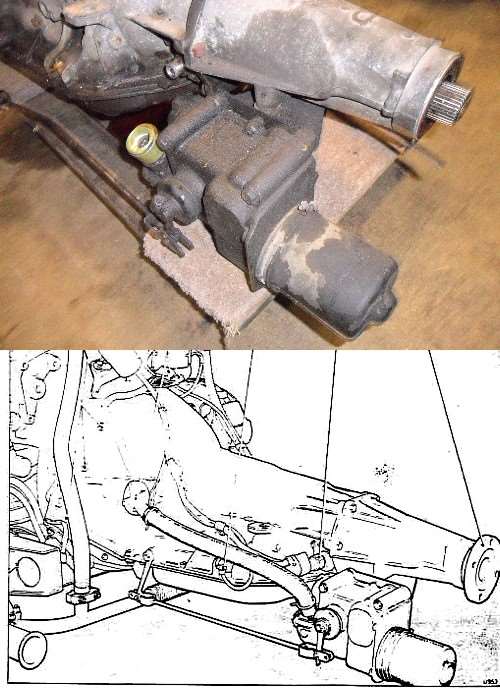

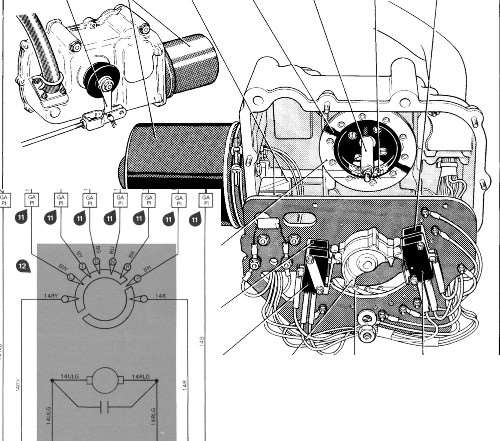

An interesting thought on the RR shift actuator. No idea how plentiful or expensive RR components are in Europe but over here the few on ebay are fairly expensive -- $200 and above. For anyone contemplating installing a GM trans in a 56 it might be worth picking one up but it looks bulky so would have to be verified if there is space available and it would mount to the GM 700R4 trans case. The actuator mounts off side to the actual transmission shift lever and motion is transmitted to the transmission portion by a rod using a standard clevis and lever arrangement at both ends. If it fits, it looks to be a rugged unit and might be more robust and reliable than the Packard actuator but if the shift detent and spacing is different then it would have the same issues as the Packard actuator.

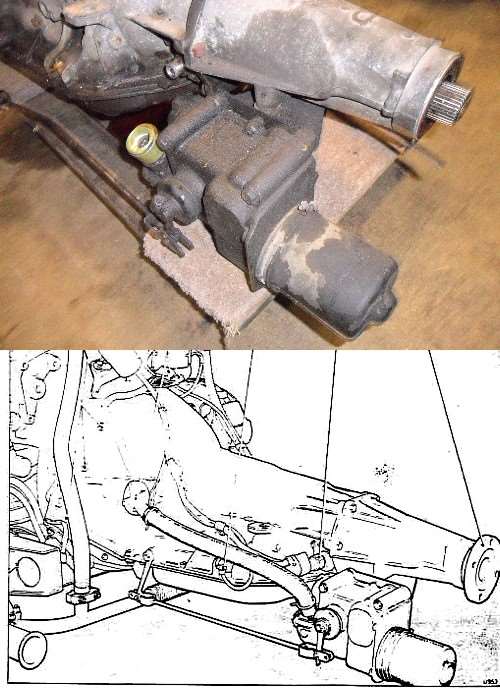

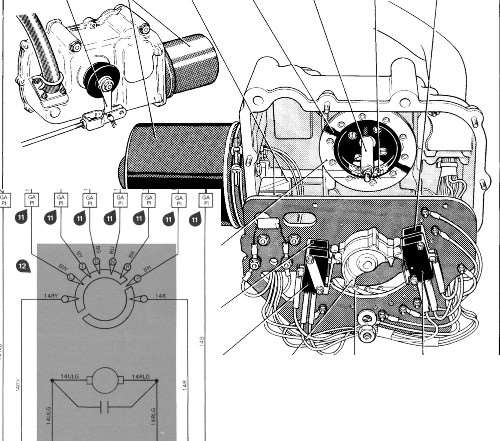

The electrical looks to be very compatible with the Packard pushbuttons. The RR uses a finger and segment arrangement almost identical to the Packard. The big difference is the RR motor is a permanent magnet so their segments select one of two relays to reverse polarity and determine which lead is grounded and which gets power. The Packard motor uses a field winding and uses its dual relay to change the relationship between armature and field. The RR relays appear to be built into the actuator case so it may be just a matter of running a few wires for power and to connect the push button wires to the RR fingers and removing the no longer needed Packard relay. Reverse lights and Park-Neutral start interlock could stay Packard. Not sure what the RR uses in place of the pressure switch to prevent accidental shifting into park or reverse while in forward motion but that would have to be sorted out.

Since the RR actuators are expensive and not growing on trees, just seeing that arrangement makes me believe more than ever the Packard motor could be adapted by casting a new finger block out of urethane plastic to reflect the different GM layout and spacing. Machine a shaft to fit and attach to the sector gear and then add a lever on the end with a rod to connect to the GM lever. A new mounting plate to support the new shaft and place the Packard assy in the same location as the RR should be relatively easy. That way the entire Packard electrical portion could be kept intact.

If I had a 700R4 transmission I would give the bench work portion of adapting the actuator a go but trying to haul a trans out of a junkyard or buying a rebuilt and having it shipped out is no longer feasible because I know I would never get around to installing it.

Attach file:

(164.11 KB)

(164.11 KB)

(131.84 KB)

(131.84 KB)

The electrical looks to be very compatible with the Packard pushbuttons. The RR uses a finger and segment arrangement almost identical to the Packard. The big difference is the RR motor is a permanent magnet so their segments select one of two relays to reverse polarity and determine which lead is grounded and which gets power. The Packard motor uses a field winding and uses its dual relay to change the relationship between armature and field. The RR relays appear to be built into the actuator case so it may be just a matter of running a few wires for power and to connect the push button wires to the RR fingers and removing the no longer needed Packard relay. Reverse lights and Park-Neutral start interlock could stay Packard. Not sure what the RR uses in place of the pressure switch to prevent accidental shifting into park or reverse while in forward motion but that would have to be sorted out.

Since the RR actuators are expensive and not growing on trees, just seeing that arrangement makes me believe more than ever the Packard motor could be adapted by casting a new finger block out of urethane plastic to reflect the different GM layout and spacing. Machine a shaft to fit and attach to the sector gear and then add a lever on the end with a rod to connect to the GM lever. A new mounting plate to support the new shaft and place the Packard assy in the same location as the RR should be relatively easy. That way the entire Packard electrical portion could be kept intact.

If I had a 700R4 transmission I would give the bench work portion of adapting the actuator a go but trying to haul a trans out of a junkyard or buying a rebuilt and having it shipped out is no longer feasible because I know I would never get around to installing it.

Attach file:

(164.11 KB)

(164.11 KB)

(131.84 KB)

(131.84 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=190419