Re: Oil pressure problems, maybe.

Posted by HH56 On 2016/7/18 14:08:47

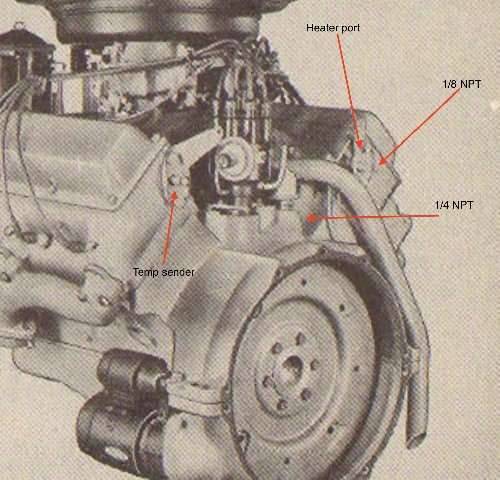

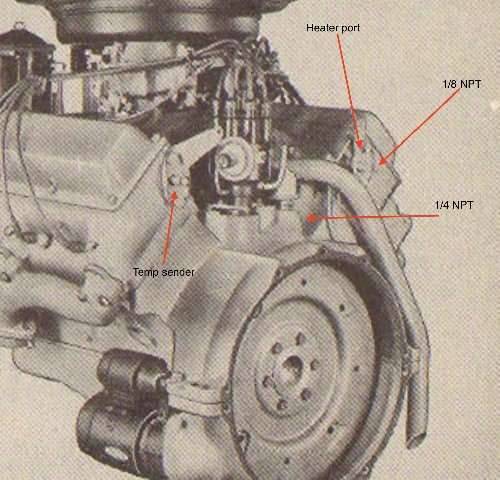

Coolant is probably from the overflow tube if in the front but the Ultra oil cooler is also up front near the vibration damper so still a possibility. Anything leaking coolant at the rear of the engine would be on the end of heads. On the left head is the temp sender and on the right head is the heater take off. Those items are both threaded into brackets bolted over a water opening with a gasket to prevent leaking.

An additional oil sender can be placed in a couple of spots without interfering with anything else. Easiest and place most use would be a spot located just below the oil sender. It is a plugged 1/4 NPT port coming off at about a 45 degree angle to the original sender. Because of the 45 degrees, if you are going to add another sender then depending on how large the new sender is you might have to add a couple of other fittings to clear the head.

The other empty spot is a plugged 1/8 NPT port on the right head just to the outside of the heater connection. Unless the engine is out and accessible, that one is harder to work with because of the limited space to firewall and the heater box and hose connection you would have to work around. During a rebuild, an elbow can be easily installed in the location with a tube for a mechanical gauge attached. There is a corresponding port on the front of the left head that the oil filter attaches to and while it could be used, because of the filter there would be more involved.

The fuel pump should be rebuildable but you would need to identify it to get the correct kit. If you don't know what application the pump is from Then and Now automotivehttp://then-now-auto.com can help identify which pump you have and provide a kit. They are moving to a new website and all their kits are not shown yet so it may take a phone call. If you know the application then probably a regular parts store can provide a kit.

Many of us have installed a pulse or solenoid type electric pump near the fuel tank and let it pump thru the mechanical pump. By pushing fuel and pressurizing the input side line it is felt by many to be the most effective location for helping avoid vapor lock. Place a fuse and on/off switch in the power line so the pump can be used for priming and possible vapor lock situations but switched off for normal use. Pulse style pumps will allow fuel to be pulled thru by the mechanical pump but most rotary styles will not.

Attach file:

(232.51 KB)

(232.51 KB)

An additional oil sender can be placed in a couple of spots without interfering with anything else. Easiest and place most use would be a spot located just below the oil sender. It is a plugged 1/4 NPT port coming off at about a 45 degree angle to the original sender. Because of the 45 degrees, if you are going to add another sender then depending on how large the new sender is you might have to add a couple of other fittings to clear the head.

The other empty spot is a plugged 1/8 NPT port on the right head just to the outside of the heater connection. Unless the engine is out and accessible, that one is harder to work with because of the limited space to firewall and the heater box and hose connection you would have to work around. During a rebuild, an elbow can be easily installed in the location with a tube for a mechanical gauge attached. There is a corresponding port on the front of the left head that the oil filter attaches to and while it could be used, because of the filter there would be more involved.

The fuel pump should be rebuildable but you would need to identify it to get the correct kit. If you don't know what application the pump is from Then and Now automotivehttp://then-now-auto.com can help identify which pump you have and provide a kit. They are moving to a new website and all their kits are not shown yet so it may take a phone call. If you know the application then probably a regular parts store can provide a kit.

Many of us have installed a pulse or solenoid type electric pump near the fuel tank and let it pump thru the mechanical pump. By pushing fuel and pressurizing the input side line it is felt by many to be the most effective location for helping avoid vapor lock. Place a fuse and on/off switch in the power line so the pump can be used for priming and possible vapor lock situations but switched off for normal use. Pulse style pumps will allow fuel to be pulled thru by the mechanical pump but most rotary styles will not.

Attach file:

(232.51 KB)

(232.51 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=179207