Re: Ignition key cylinder removal

Posted by HH56 On 2018/1/2 12:54:04

Here are some photos of the 55-6 Packard ign switch and cylinder. If the switch is an aftermarket the instructions may not work because there are about as many ways to release a cylinder as there are aftermarket switches. Some have different locations for the retainer so need the cylinder to be in different positions. Some have no external holes at all and are considered throw away if they fail or keys are lost.

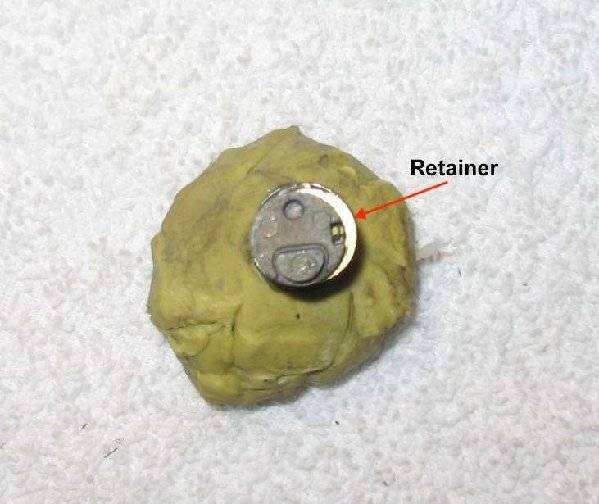

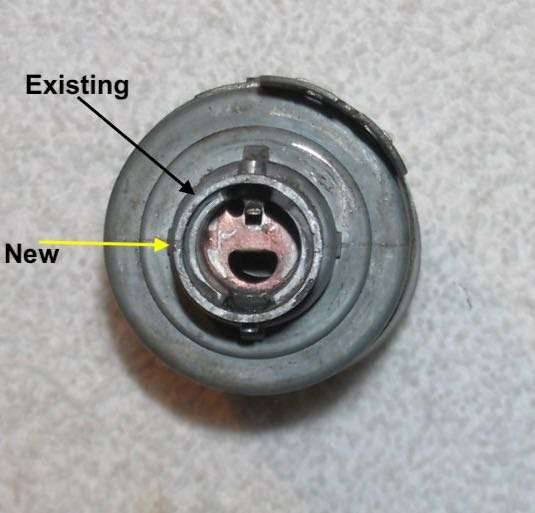

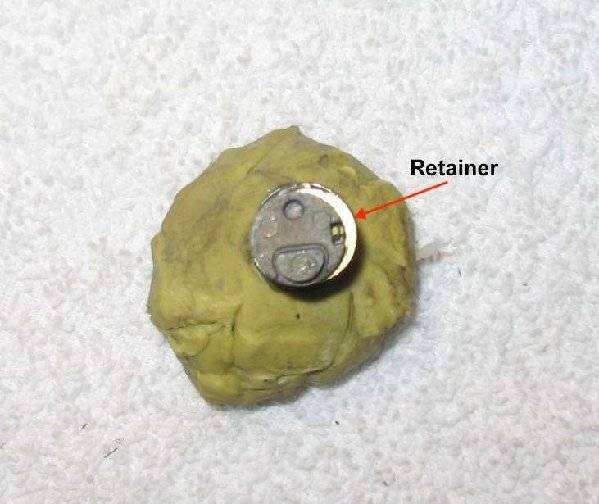

Normally for the Packard switch the key is needed so the cylinder can be turned to the ON or run position to bring the cylinder retainer clip in line with the hole in the case. A heavy paper clip or small diameter rod or drillbit end that fits the hole is pushed in to press the retainer clip against it's springs and, with the tumblers not allowing the key to be removed, pulling the key allows you to withdraw the cylinder.

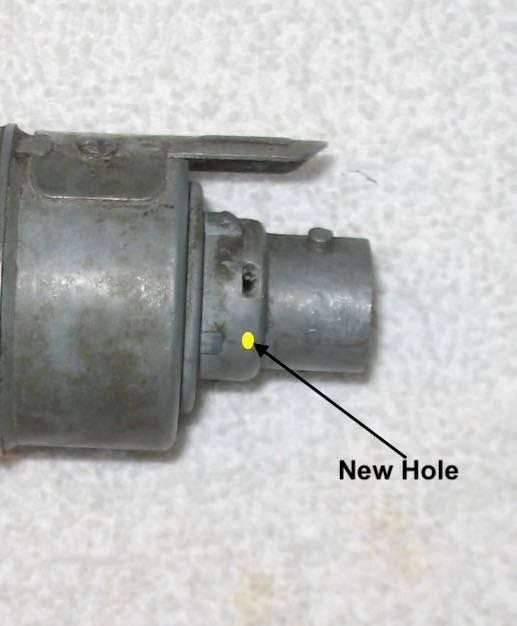

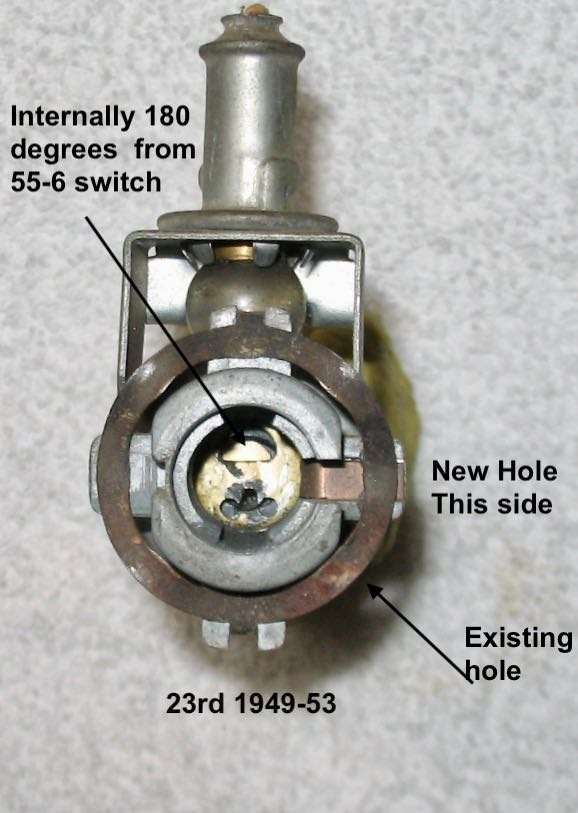

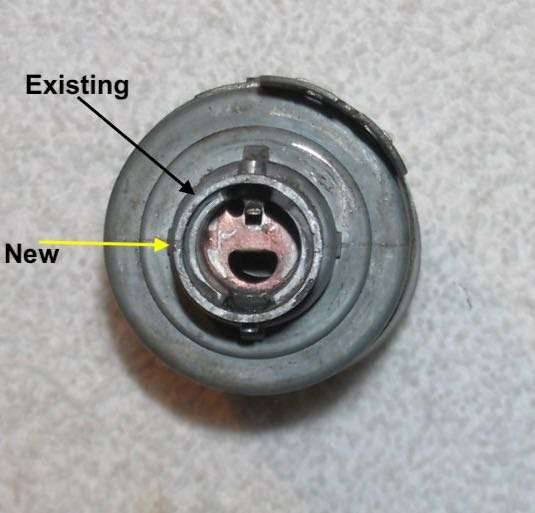

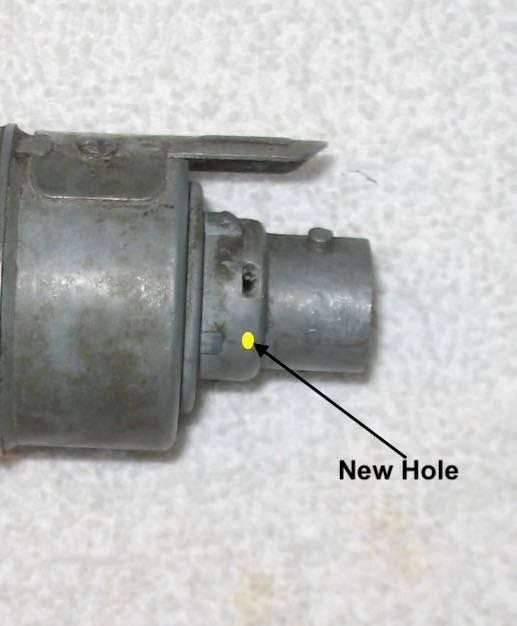

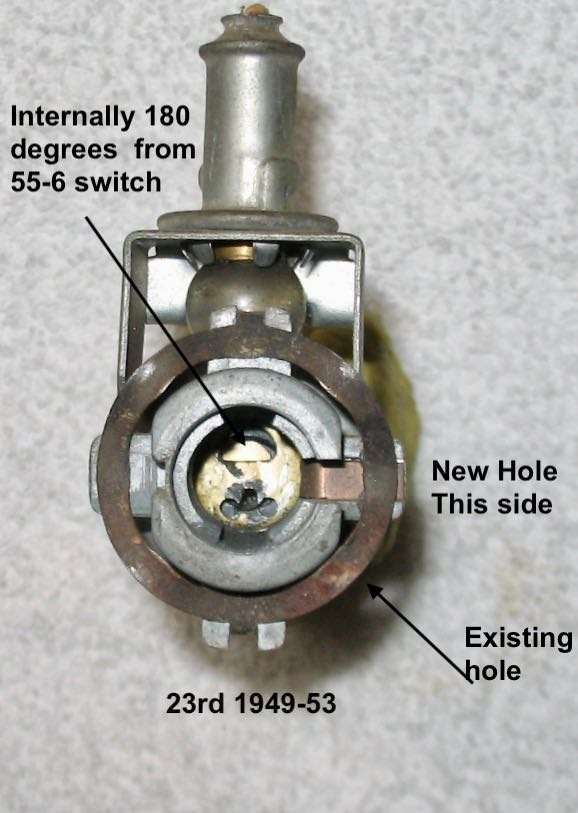

With no key and no way to turn the cylinder to line up the retainer you will need to drill another hole that would be in line with where the retainer is positioned when ign is in the OFF position; That should be at the indicated spot or in line with the small square tab on the case in one direction and in line with the existing hole in the other. The same size hole or no larger than 3/32 is CAREFULLY drilled paying attention to depth so it barely penetrates the case. Any deeper and you run the risk of damaging the retainer to the point it gets a burr or is bent and will not push in to release.

Once the hole is drilled insert the rod and push the retainer in against the spring. Since there is no key locked in place to help withdraw the cylinder you will need to find another way to grip and pull while still keeping pressure on the retainer. If the hole is not precise you may be able to insert the rod at an angle and still catch the retainer and push it in but do not force anything. The retainer is brass and easily bent.

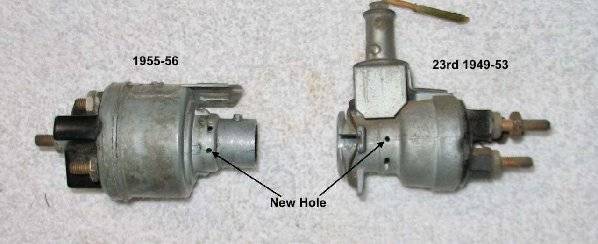

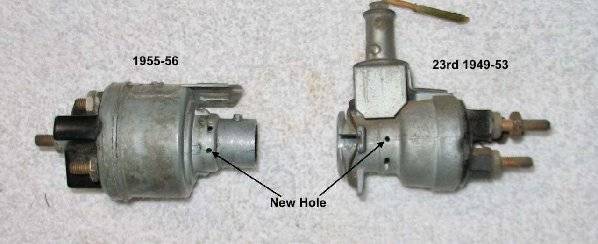

EDIT: Added a photo showing the extra hole needed for the 55-6 switch and also if there is no key for a 23rd 1949 - 53 switch. The 49-53 switch uses the same cylinder but has the internal piece 180 from the 55-6 switch so the hole is drilled on the opposite side from 55-6. There is a faint casting line or mold line in the potmetal at the spot the hole should be drilled.

Attach file:

(40.36 KB)

(40.36 KB)

(28.82 KB)

(28.82 KB)

(26.33 KB)

(26.33 KB)

(59.12 KB)

(59.12 KB)

(47.75 KB)

(47.75 KB)

Normally for the Packard switch the key is needed so the cylinder can be turned to the ON or run position to bring the cylinder retainer clip in line with the hole in the case. A heavy paper clip or small diameter rod or drillbit end that fits the hole is pushed in to press the retainer clip against it's springs and, with the tumblers not allowing the key to be removed, pulling the key allows you to withdraw the cylinder.

With no key and no way to turn the cylinder to line up the retainer you will need to drill another hole that would be in line with where the retainer is positioned when ign is in the OFF position; That should be at the indicated spot or in line with the small square tab on the case in one direction and in line with the existing hole in the other. The same size hole or no larger than 3/32 is CAREFULLY drilled paying attention to depth so it barely penetrates the case. Any deeper and you run the risk of damaging the retainer to the point it gets a burr or is bent and will not push in to release.

Once the hole is drilled insert the rod and push the retainer in against the spring. Since there is no key locked in place to help withdraw the cylinder you will need to find another way to grip and pull while still keeping pressure on the retainer. If the hole is not precise you may be able to insert the rod at an angle and still catch the retainer and push it in but do not force anything. The retainer is brass and easily bent.

EDIT: Added a photo showing the extra hole needed for the 55-6 switch and also if there is no key for a 23rd 1949 - 53 switch. The 49-53 switch uses the same cylinder but has the internal piece 180 from the 55-6 switch so the hole is drilled on the opposite side from 55-6. There is a faint casting line or mold line in the potmetal at the spot the hole should be drilled.

Attach file:

(40.36 KB)

(40.36 KB)

(28.82 KB)

(28.82 KB)

(26.33 KB)

(26.33 KB)

(59.12 KB)

(59.12 KB)

(47.75 KB)

(47.75 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=198989