Re: Treadle vac disassembly snag

Posted by HH56 On 2019/5/26 9:50:25

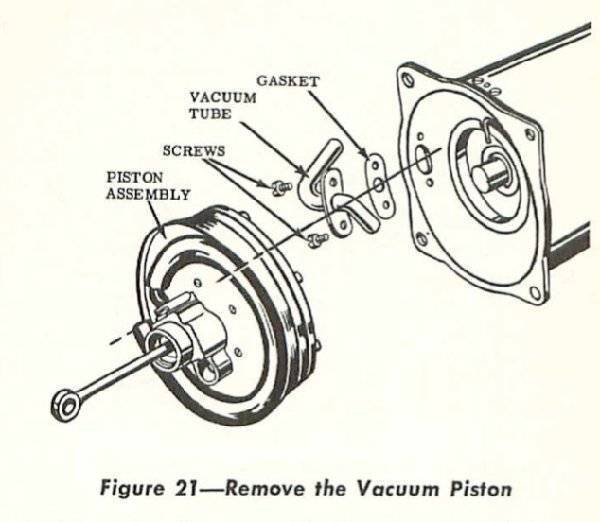

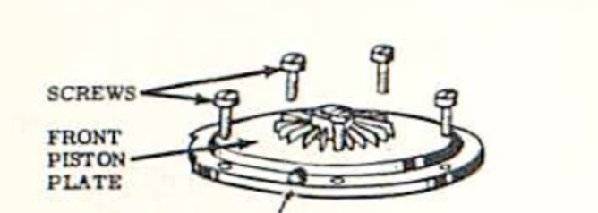

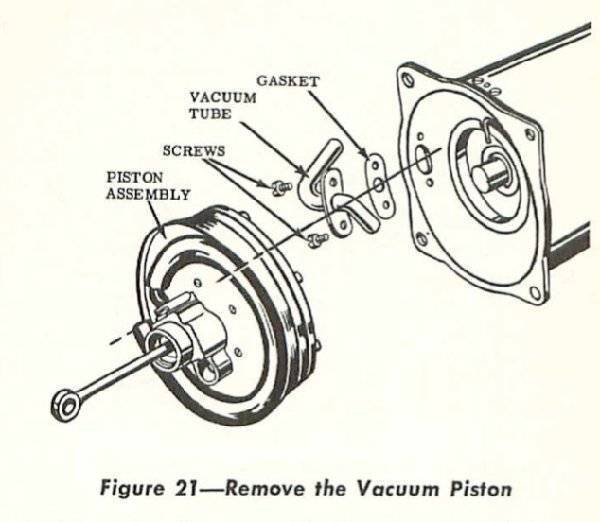

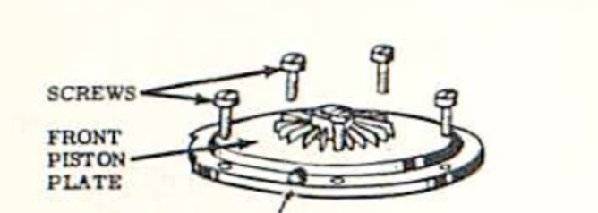

The connection only consists of a socket or rather a closed end hole on the front portion of the power piston casting that the end of the ram slides into. It is only about a 1/4 to 1/2 inch deep and there is no mechanical fastening between the two. Maybe fluid has leaked into the vacuum section and crystallized and hardened or maybe other moisture has corroded the pot metal and the swelling has locked the two together..

There is no way to get behind the piston so I think about all you can do is gently hold the entire BTV unit in something to keep it steady and firm then grab onto the large bump protruding from the front half of the power piston around the actuating shaft where the valve mechanism is housed. Try rocking the power piston slightly up and down, side to side to see if you can break the bond while at the same time giving force to pull the entire piston out. Rotation may not do much good because the ram would try and rotate with the power piston. It might be possible to reach thru the compensator port to hold the ram with something but you would need to be very careful not to scratch or otherwise damage it so it could no longer seal.

There is a leather around the piston which is snug to the vacuum shell but there should be some give and take to allow a slight bit of rocking. I would try and not pull much on the actual actuating shaft that attaches to the pedal because it is attached to the valve mechanism and could damage the valve mechanism if a lot of sideways pull pressure is being applied.

If that doesn't work and you don't want to risk damaging the unit making it worthless then maybe an exchange for an already rebuilt BTV from Kanter or Max or sending yours to Ross or Kanter for a rebuild by someone familiar with the quirks of the unit is the next best answer. While the rebuild kit has essential parts the BTV hydraulic functions are different from most units. There are places where damage might be found and a couple of parts that can fail are not in the kit. If something is missed or skipped over omissions can lead to poor operation or even sudden failure.

Attach file:

(35.05 KB)

(35.05 KB)

(16.65 KB)

(16.65 KB)

There is no way to get behind the piston so I think about all you can do is gently hold the entire BTV unit in something to keep it steady and firm then grab onto the large bump protruding from the front half of the power piston around the actuating shaft where the valve mechanism is housed. Try rocking the power piston slightly up and down, side to side to see if you can break the bond while at the same time giving force to pull the entire piston out. Rotation may not do much good because the ram would try and rotate with the power piston. It might be possible to reach thru the compensator port to hold the ram with something but you would need to be very careful not to scratch or otherwise damage it so it could no longer seal.

There is a leather around the piston which is snug to the vacuum shell but there should be some give and take to allow a slight bit of rocking. I would try and not pull much on the actual actuating shaft that attaches to the pedal because it is attached to the valve mechanism and could damage the valve mechanism if a lot of sideways pull pressure is being applied.

If that doesn't work and you don't want to risk damaging the unit making it worthless then maybe an exchange for an already rebuilt BTV from Kanter or Max or sending yours to Ross or Kanter for a rebuild by someone familiar with the quirks of the unit is the next best answer. While the rebuild kit has essential parts the BTV hydraulic functions are different from most units. There are places where damage might be found and a couple of parts that can fail are not in the kit. If something is missed or skipped over omissions can lead to poor operation or even sudden failure.

Attach file:

(35.05 KB)

(35.05 KB)

(16.65 KB)

(16.65 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=211917