Re: Speedometer tips?

Posted by HH56 On 2020/9/11 22:20:58

The sleeve or bushing surrounding the rotating portion the cable end inserts into has undoubtedly become dry and the symptom is exactly what you have had happen. If it gets any worse the speedo could start jerking and the inertia will twist the needle off the shaft.

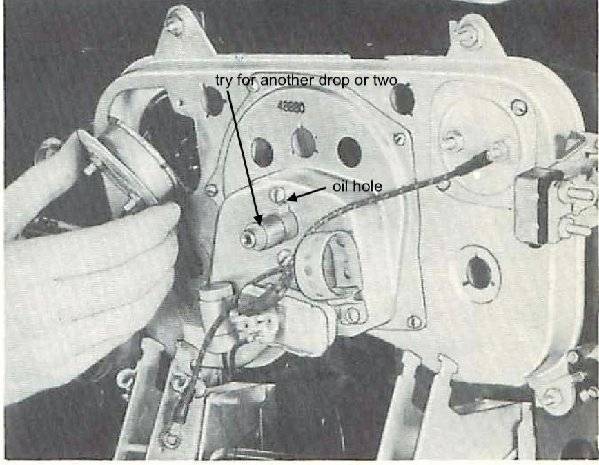

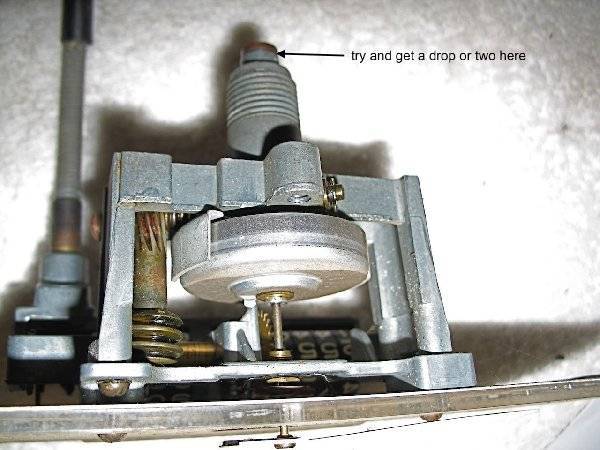

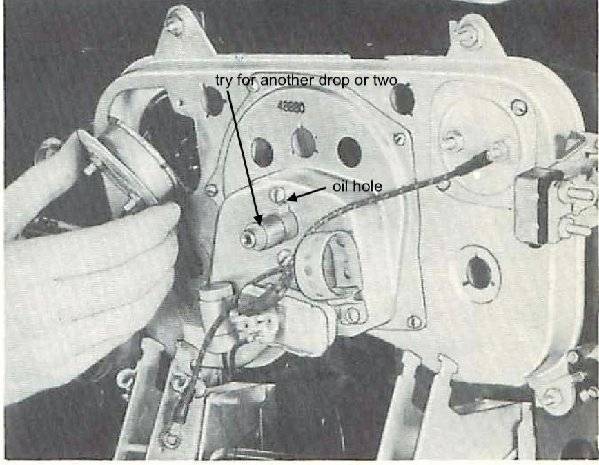

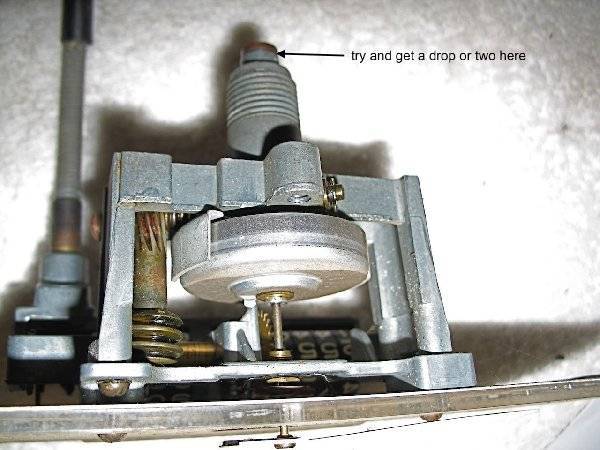

You may be able to reach the oil hole and wick to lube with a light machine oil frequently found in the tube type applicators that come with a needle point. The hole is generally located in a squarish protrusion just behind the threads for the nut if the sheetmetal cover or a mounting screw has not partially obstructed it. If accessible you can try a few drops there and also try to get a drop or two in the space just behind the rotating portion and the solid part of the casting where the threads are. Check to see exactly where the part that rotates is located and then add a drop or two behind it and try to work it into the area at the end of the bushing. On some speedos there is a definite change of metals and colors so you can see the place. On others the rotating portion is more hidden with similar metals. I don't remember exactly how the 55-6 units are.

If you cannot access the hole then the speedo will need to come out. There is a worm gear and a gear train to the odometer portion inside that could also have dried or caked on grease that might be worth checking. For that the speedo will need to come out and have the cover removed.

Here is a cluster photo from the SM showing the locations and a 54 unit showing better detail of the oil hole and the area to try and get another drop or two of oil.

Attach file:

(75.17 KB)

(75.17 KB)

(117.03 KB)

(117.03 KB)

(132.72 KB)

(132.72 KB)

You may be able to reach the oil hole and wick to lube with a light machine oil frequently found in the tube type applicators that come with a needle point. The hole is generally located in a squarish protrusion just behind the threads for the nut if the sheetmetal cover or a mounting screw has not partially obstructed it. If accessible you can try a few drops there and also try to get a drop or two in the space just behind the rotating portion and the solid part of the casting where the threads are. Check to see exactly where the part that rotates is located and then add a drop or two behind it and try to work it into the area at the end of the bushing. On some speedos there is a definite change of metals and colors so you can see the place. On others the rotating portion is more hidden with similar metals. I don't remember exactly how the 55-6 units are.

If you cannot access the hole then the speedo will need to come out. There is a worm gear and a gear train to the odometer portion inside that could also have dried or caked on grease that might be worth checking. For that the speedo will need to come out and have the cover removed.

Here is a cluster photo from the SM showing the locations and a 54 unit showing better detail of the oil hole and the area to try and get another drop or two of oil.

Attach file:

(75.17 KB)

(75.17 KB)

(117.03 KB)

(117.03 KB)

(132.72 KB)

(132.72 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=226498