Re: Those needing door panels.

Posted by Leeedy On 2021/9/4 16:51:02

Quote:

Okay, I'm always reluctant to get into details on such stuff because of the nature of the internet and so many opinions.

What I'm telling you is not opinion. It is only what I know after having spent a lifetime in the automotive industry.

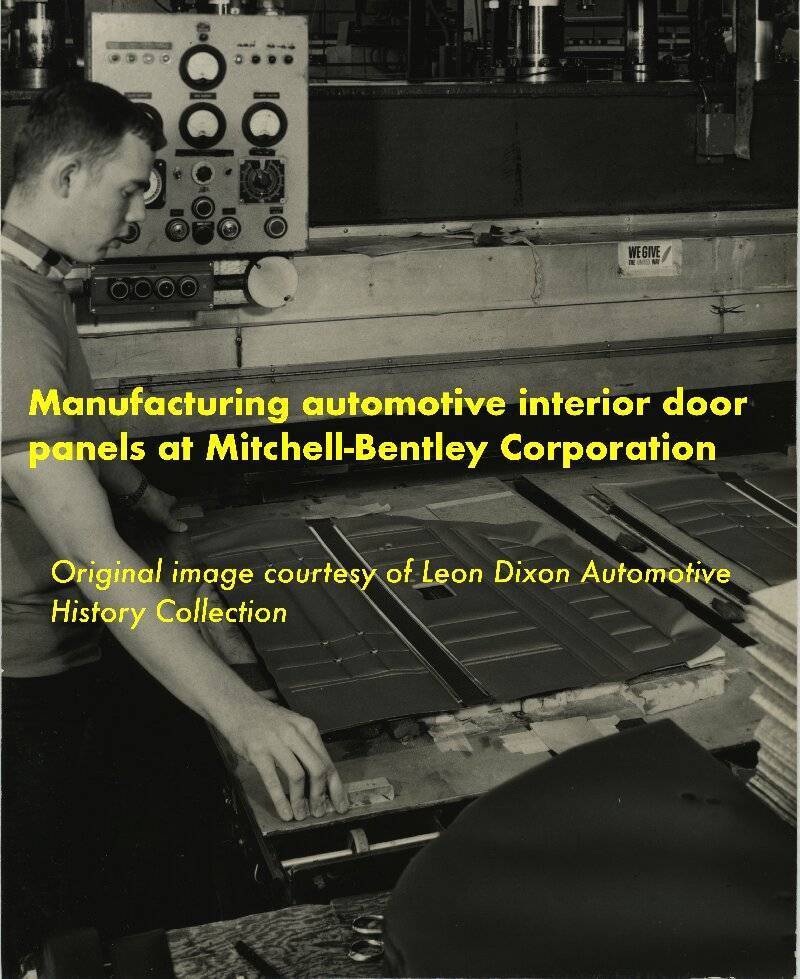

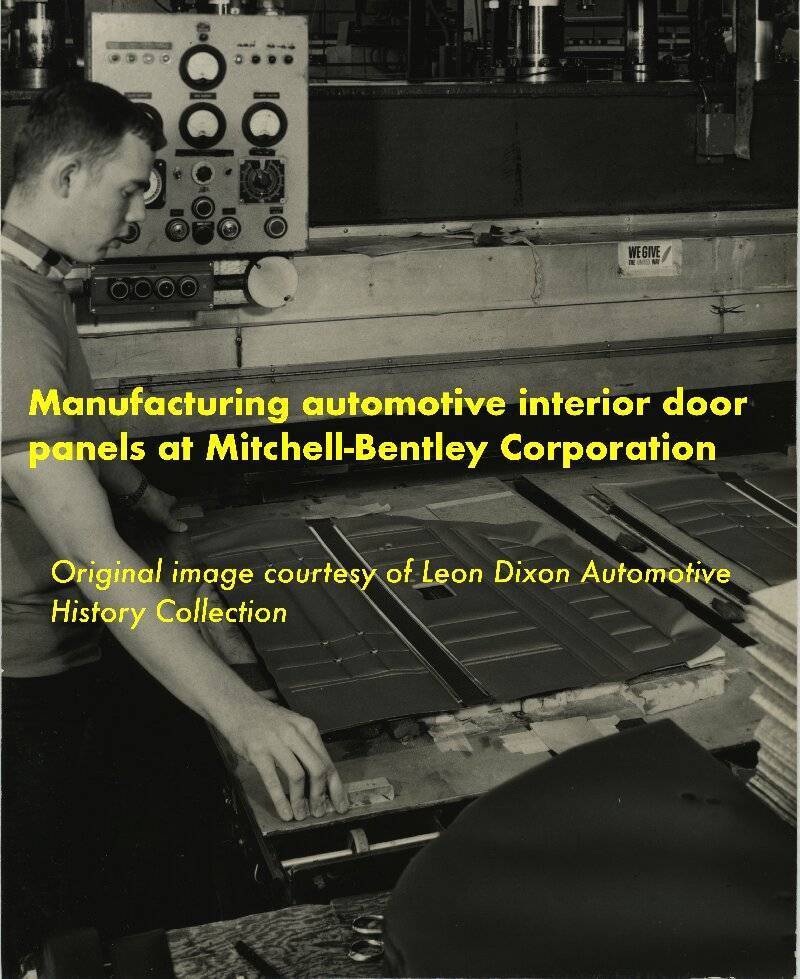

What I said about Mitchell-Bentley's process is simply fact. I saw them making panels such as these with my own eyes. They made millions in their plants.

While an aftermarket trim company today could likely duplicate the embossing, it could only be done at great expense unless economies of scale are involved, such as doing Chevy repops at a few thousand per run. Otherwise the cost of making dies, fixtures and patterns would be absolutely crushing on a onesy-twosy basis.

I am attaching an original photo of some embossed door panels being made at M-B. Even with HUGE machinery, dies, lots of steam and lots of workers, these things were not cheap.

As for skipping the embossing...if it's not worth doing right, then it's not worth doing at all. There used to be a difference between "restoration" and "customizing" even if these two concepts have sadly been morphed together by folks today.

Take your time and SAVE any savable embossed sections on your door panels. Clean them properly. Preserve them... and insert into any reconstituted panel whenever possible. There are undoubtedly still some talented auto trim shops and trimmers left around today. But never imagine that some company today can do an affordable reproduction– even if such miracles can occur. Keeping a trimmer or trim shop on tab while the meter is running can really put a hitch in your get-a-long.

With unlimited time, talent and energy certainly you can build or own dies or make male and female molds, locate suitable fabrics and shrink-mold your way into embossing.

Of course, if you have a Bill Gates or Elon Musk-sized wallet, then anything is possible.

My sincere advice is to take very, very good care of what you have already.

Attach file:

M-BheatEmbossedDoorPanelsWM.jpg (233.01 KB)

M-BheatEmbossedDoorPanelsWM.jpg (233.01 KB)

kevinpackard wrote:

Quote:

Leeedy wrote:

The panel shown here appears to have been made by Mitchell-Bentley. They did a lot of Packard's interiors in the 1950s.

This panel was made using a combination of heat-embossing, steam, and attached metal components with a pressed, un-tempered masonite or similar fiberboard backing. Very complicated door panel. The difficult part here was not the fabrics... it was the embossing (and related dies), the attachments, and frankly, the labor and machinery involved. Very tough to replicate.

Thank you Leeedy, that is information that is new to me. I haven't found much on the internet about embossed door panels, but what I did find looked like it involved very specialized machinery and dies.

So if not SMS, what are the options for someone like me who needs this type of embossing? Any way to DIY it without it looking terrible?

-Kevin

Okay, I'm always reluctant to get into details on such stuff because of the nature of the internet and so many opinions.

What I'm telling you is not opinion. It is only what I know after having spent a lifetime in the automotive industry.

What I said about Mitchell-Bentley's process is simply fact. I saw them making panels such as these with my own eyes. They made millions in their plants.

While an aftermarket trim company today could likely duplicate the embossing, it could only be done at great expense unless economies of scale are involved, such as doing Chevy repops at a few thousand per run. Otherwise the cost of making dies, fixtures and patterns would be absolutely crushing on a onesy-twosy basis.

I am attaching an original photo of some embossed door panels being made at M-B. Even with HUGE machinery, dies, lots of steam and lots of workers, these things were not cheap.

As for skipping the embossing...if it's not worth doing right, then it's not worth doing at all. There used to be a difference between "restoration" and "customizing" even if these two concepts have sadly been morphed together by folks today.

Take your time and SAVE any savable embossed sections on your door panels. Clean them properly. Preserve them... and insert into any reconstituted panel whenever possible. There are undoubtedly still some talented auto trim shops and trimmers left around today. But never imagine that some company today can do an affordable reproduction– even if such miracles can occur. Keeping a trimmer or trim shop on tab while the meter is running can really put a hitch in your get-a-long.

With unlimited time, talent and energy certainly you can build or own dies or make male and female molds, locate suitable fabrics and shrink-mold your way into embossing.

Of course, if you have a Bill Gates or Elon Musk-sized wallet, then anything is possible.

My sincere advice is to take very, very good care of what you have already.

Attach file:

M-BheatEmbossedDoorPanelsWM.jpg (233.01 KB)

M-BheatEmbossedDoorPanelsWM.jpg (233.01 KB)

This Post was from: https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=236599