|

Re: How do I clean an oil bath air filter?

|

||||

|---|---|---|---|---|

|

Just popping in

|

Thanks very much. I have noticed that in going thru the manual, there are parts here and there that appear to be vague. But I'm assuming they wrote it with the intent of the reader being a mechanic, so certain things might be assumed.

Posted on: 2008/6/1 13:30

|

|||

|

Greg

'56 Clipper Deluxe |

||||

|

||||

|

Re: Reproduction Rear Wheel Arches?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well, since I have been asking on the forum, and around my neighborhood shops here, I've gotten a lot of options... I'll give "classicparts" a shot, and if the parts don't satisfy me then I'll chalk it up as "Lern Geld" (education money) and fab the parts locally. I think the work will be done in the fall either with parts I ship from the US, or made here.

Tobs I also learned how to say "bondo" in german, "spachtel" in case anybody was wondering

Posted on: 2008/6/1 13:28

|

|||

|

||||

|

Re: How do I clean an oil bath air filter?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

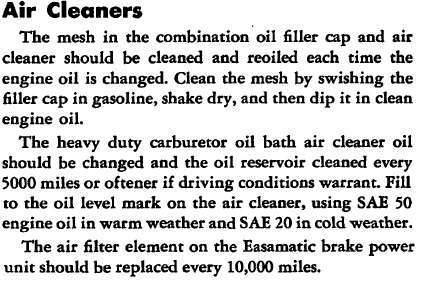

That statement is a bit vague but the elements are about the same--one just has more air flow than other.

The mesh is normally kept moist by the oil in bowl sloshing up and thru wicking and air flow, carried up thru element leaving just enough residue to trap dirt particles. The heavy stuff (insects etc) can't penetrate and fall to bottom but the dirt particles will move up a bit so the occasional slosh is necessary. I use either solvent or kerosene and just give a quick dip & swirl to lower half, shake excess and then pour a bit of oil in and let it drain while doing something else.

Posted on: 2008/6/1 13:03

|

|||

|

||||

|

Re: How do I clean an oil bath air filter?

|

||||

|---|---|---|---|---|

|

Just popping in

|

I saw that blurb in my manual but wasn't sure if it applied to the air filter also since it does specify to "swish the filler cap in gasoline, then dip it in clean engine oil".

Is gas the only acceptable solution to clean it with? And when "dipping the air filter", do you really dip it or does one pour some oil in and let it drain out the excess?

Posted on: 2008/6/1 12:39

|

|||

|

Greg

'56 Clipper Deluxe |

||||

|

||||

|

Re: '39 Model 110 brake drum max. inside diameter?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Another thing to check is the brake pedal free play. If there is none, then pressure will build-up in the system expanding the shoes against the drum. I have heard of brakes being locked up with this condition and even getting so hot as to start a fire. It is easily adjusted with the rod between the pedal and master cylinder. Adjustment should yield around one-half inch. This must be checked by hand. Check your shop/repair manual for the procedure and free play amount. Regards - John

Posted on: 2008/6/1 12:31

|

|||

|

||||

|

Re: How do I clean an oil bath air filter?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

From the 56 Service Manual.

With the price and all the modern crap added to gas, maybe kerosene instead since there are different type elements (metal, synthetic etc) and who knows what additive might not be compatible today. I give the air filter a quick slosh, the big stuff stays in the bowl oil and unless you are in a prolonged dust storm, it shouldn't require too much service--just the oil change and clean bowl. Attach file:  (31.57 KB) (31.57 KB)

Posted on: 2008/6/1 12:12

|

|||

|

||||

|

How do I clean an oil bath air filter?

|

||||

|---|---|---|---|---|

|

Just popping in

|

The subject line says it all. I've had this car for about a year but just got it running recently after getting the fuel tank re-newed.

Posted on: 2008/6/1 11:09

|

|||

|

Greg

'56 Clipper Deluxe |

||||

|

||||

|

Re: Reproduction Rear Wheel Arches?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

We have much experience with sheet meatl work. The arches are no problem as are the rockers. We have sheet metal quality tools at our disposal. I personally fabricated the curved rear middle section of the rear tail pan of a 53 clipper, an dmy bro welded it in This same part would have fit all the cars those years. These were made from 18 gauge steel welded in place. We also have the rollers to put the strength channels in the floor boards to look original. Check out pic's. Many more pic's available. For god sake fix it right for ever. Don't settle for cheap quality

Posted on: 2008/6/1 10:51

|

|||

|

||||

|

Re: blood guts and the beer

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I was just kidding about the beer can method of checking line bore. The 359 had a bad rear main seal leak. After I changed that in the car I plasti-gauged the rear bearing and found .0035 clearance. Not good so I pulled motor and check all the bearings.The rods were in @.0015 and that is good but the crank had score marks. I decided to have the crank turned .010 - .010. The new tolerances will be held to .0015on all. I like em tight. The cam bearings looked rough so I'll replace them. Thank God the valve train look good. New hydraulic Lifters are expensive at $800.00 a set plus shipping. Then you have the hassle of dial indicating the valve stems for length and taking them to machine shop for cutting. I use this same method for the Packard V-8's as well as I have never found any written spec's on correct Valve stem length and when you install new valves you have to indicate and cut. Has anyone heard the story of where new straight 8 lifters come from. It is interesting and I was told by the source but I was sworn not to tell. If any one knows tell. The valves in the 359 will be re-seated. The pistons will have new rings and proper power honing done but first the pistons will come off rods for I can have the rotating mass Precision Balanced. A new timing chain and a rebuilt distributor from a 327 will be installed so I can back off the vacuum advance set by factory from 359 dist. This will help spark knock (pinging) cuased by Packard's inherent poor flame travel in combustion chamber. I'll top the motor off with the found cherry aluminum head and 2 head gaskets. 2 gaskets will improve on poor flame travel and drop compression. I am rebuilding this motor for re-liability. The exhaust manifold was sent off to be jet hot coated "cast gray" to preserve it. As far as the oil filter goes it is very week system. Even worse on the V-8's. The filter is last in line where it should be first. Eventually all oil should get a once through the filter but by that time you probably should change the oil any way. I'll catch slack for this one but I believe the oil filter should be removed from V-8 as the filter robs some pressure and volume from where it is needed most,,,, the oil starved lifters. The only true fix is a dry sump system and put filter first or a simple method is to just change oil more often. Look at an oil map of both engines and you'll see that filter is as useless as tits on a bore. I'll have pic's for this named forum when assembly time is here.

Posted on: 2008/6/1 10:32

|

|||

|

||||