|

Re: hph's 55 Clipper Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Also, here is how I removed my vibration damper. First, remove the bolt and washer then screw the bolt back in about half way. Get a deep well 1-1/16 socket and, very important, fill it almost all the way up with washers. For me, 3/16 washers happened to have the right OD. Then just press with the C-clamps.

Eventually once it’s mostly out, flip the socket around and loosen the bolt to be only about 1/4 threaded. This will give the reach necessary. Even more than that and you can tap LIGHTLY with a dead blow on alternating sides to bump it out. Attach file:  CE09505F-BC20-47E8-BD73-DD8CAA8EB785.jpeg (481.51 KB) CE09505F-BC20-47E8-BD73-DD8CAA8EB785.jpeg (481.51 KB)  35372281-AACD-402A-B165-671470C067D1.jpeg (462.82 KB) 35372281-AACD-402A-B165-671470C067D1.jpeg (462.82 KB)

Posted on: Yesterday 13:21

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: hph's 55 Clipper Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

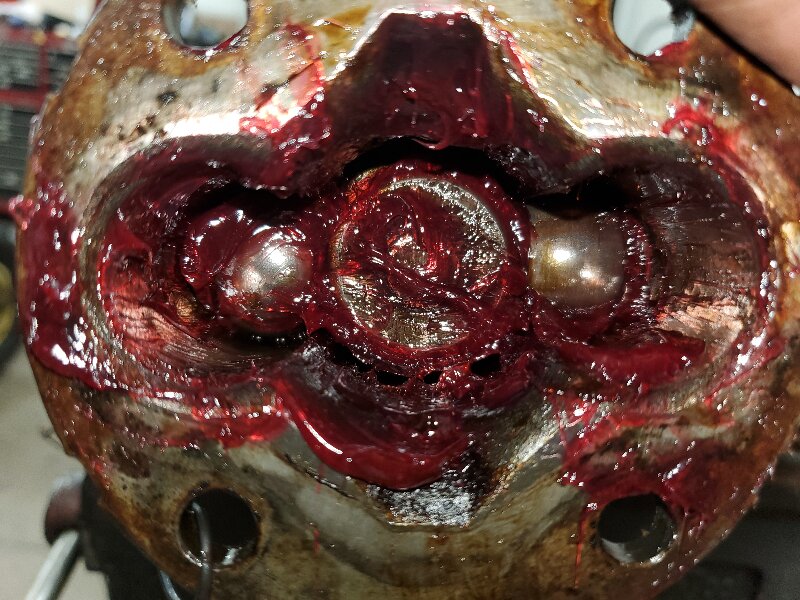

I got the rear U joint disassembled yesterday. I had to use a wrench and hammer combo to bang out one side. Literally took probably 100 hits or more. But then I could just press out the other side. Unfortunately the U joint is a bit messed up as shown in the photo. Not sure if this is from the effort it took to remove it or if it happened on the road 30+ years ago (note the metal shavings that collected in the center, so I am thinking the latter). It still spins over okay so I just repacked it and stuck it back in, but I plan to replace it before too long.

I tested the tolerance on all the main bearings except #5 and they were all 1.9-2.2 thou. I removed all the pistons; the #2 cylinder looks a bit “ruff” so I think I want to hone them and install new rings. In the meantime I can de-gunk the pistons. Attach file:  DE79BAD8-519A-4785-86A0-27FC7FEE6516.jpeg (405.37 KB) DE79BAD8-519A-4785-86A0-27FC7FEE6516.jpeg (405.37 KB)  5837573F-C72F-4554-AD28-D82A9681E723.jpeg (384.32 KB) 5837573F-C72F-4554-AD28-D82A9681E723.jpeg (384.32 KB)  ED28F154-BC86-487F-B89B-8719CDBF1570.jpeg (670.86 KB) ED28F154-BC86-487F-B89B-8719CDBF1570.jpeg (670.86 KB)  F9826AE0-1EFC-41C3-B5B1-CA27DA73399F.jpeg (674.63 KB) F9826AE0-1EFC-41C3-B5B1-CA27DA73399F.jpeg (674.63 KB)

Posted on: Yesterday 9:41

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: '51 Master Cylinder Removal

|

||||

|---|---|---|---|---|

|

Home away from home

|

"Step 1" can be ignored. Once you take the 2 bolts out and disconnect the brake lines, just slide off the master cylinder.

P.S. Where are you getting a rebuild kit? Check the parts X ref as you can probably get a whole new one for about the same price as a kit from the major vendors.

Posted on: 4/21 21:03

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: Packard organ?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Nope. The organ company actually predates the car company and I think also Packard Electric.

Likewise as far as I’m aware that Packard family had no connection with the others. Interesting story, there is a very fancy and expensive organ in the Crescent Hotel, Eureka Springs, Arkansas USA which was custom made for the Packard family (though not a Packard organ). This organ was made in Germany and was planned to be shipped, with its creator riding along for delivery, on the maiden voyage of the Titanic. But thankfully it was not completed in time! So the automotive Packards we know were certainly fans of organs, enough to buy an elaborate German organ.

Posted on: 4/21 16:04

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Solid copper, or oilite?

What's the ID, OD, length?

Posted on: 4/21 14:52

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: hph's 55 Clipper Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Bob.

I was able to make excellent progress yesterday: - I got both the rear brakes done and installed. The E brake is installed and properly adjusted. I followed the steps in the manual to a tee and it gave a very good result. As a side note, when I bought this car, the E-brake was stuck for no apparent reason. In servicing the system I couldn't find why this was, thought I think they were just adjusted completely wrong, though why the rear wheels could still spin I don't know. Note: I'll still need to disconnect the mounting plates when I service the rear axle. - I removed the driveshaft and re-lubed the ball and trunion joint with wheel bearing grease. I did notice a good amount of pitting, but the mating surfaces on the joint were still good, so I just threw it back together. Could be worse for 93k miles and sitting for 30 years. Is this a sufficient amount of grease to use? Packard warns against over lubricating the joint. I did pack the needle bearings and other parts individually. BTW, I'll probably get some Gummi Pflege to revive the boot a bit. Fortunately it seems in good shape otherwise. - I checked the #1 main bearing and #3 rod bearing tolerances with Plastigage and they were at 2.2 and 1.7 thou respectively; spec is 0.5 to 2.5. So a bit worn, but good enough to ride with 😎 (Picture shows main bearing) - Also bought some gas tank vent hose. Having a hard time re-attaching it. Any good way to get it a bit more stretchy and help it on the tank? Attach file:  20240420_210010.jpg (3,171.30 KB) 20240420_210010.jpg (3,171.30 KB)  20240420_210058.jpg (6,552.91 KB) 20240420_210058.jpg (6,552.91 KB)  20240420_212046.jpg (6,569.95 KB) 20240420_212046.jpg (6,569.95 KB)  20240420_215443.jpg (4,809.54 KB) 20240420_215443.jpg (4,809.54 KB)

Posted on: 4/21 8:11

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: hph's 55 Clipper Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Trying to remove my U joint. Bearings do not want to come out even with a hydraulic press. What to do?

I took the 2 clips off already btw.

Posted on: 4/20 19:35

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: hph's 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Clearly all gold in this brochure. Would be curious what you can get in silver.

Except hood letters which I forgot to mention were chrome on all models. https://packardinfo.com/xoops/html/modules/archive/content.php?op=&catID=5&ContentID=554

Posted on: 4/20 11:13

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: hph's 55 Clipper Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

What is this garbage in my wheel cylinder?

I'm replacing them anyway; I'm just curious.

Posted on: 4/20 11:10

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: Ultramatic Disassembly

|

||||

|---|---|---|---|---|

|

Home away from home

|

(For Twin Ultras)

As many of us know, the torque converter reactor endplay must be between .010 and .017, and the manual says to adjust this by replacing the "first turbine thrust washer" 3.6233 to one of a thicker size. However there are 3 thrust washers total in the assembly: - 3.6233 (above) between the clutch housing and first turbine - 3.6163 between the first turbine and reactor - 3.6173 between the reactor and pump Since of course the pump is bolted to the clutch housing, these 3 are sufficient to keep everything "spaced apart". Is it ever necessary that the two other thrust washers wear enough to need replacement? The parts book indicates only up to 0.48 oversize on the 3.6233 washer.

Posted on: 4/20 8:43

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||