|

Re: '53 Caribbean

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

My '48 Custom 8 was painted grey (I used Ford grey engine paint when I repainted it.) My '48 Std 8 was green, but someone may have repainted it in the last 67 years.

M.

Posted on: 2015/9/9 9:48

|

|||

|

||||

|

Re: Valve Timing correction for '48 356 Engine

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

My shop manual says that the #8 exh valve timing is to be used for checking the timing on the hydraulic lifter engines. I looked in another manual to see what the inlet valve timing is supposed to be and noted that it is supposed to open slightly before TDC...I checked my #8 cyl inlet valve and it is starting to open late. (If you had a solid lifter engine with large tappet clearances it seems like this would be the result.)

Now...could the hydraulic lifters not being full of oil have any effect on this? I bled-down all the lifters before re-installing the camshaft. Later in the day I'll pre-oil the engine and fill the crankcase with oil. Then I'll rotate the engine several revolutions to see if I can pump the lifters full of oil. Then I'll recheck the valve timing. M.

Posted on: 2015/9/9 9:43

|

|||

|

||||

|

Valve Timing correction for '48 356 Engine

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I just replaced a chipped cam follower on my '48 356 cu. in. engine. I did the timing check as described in the shop manual and find that the #8 exhaust valve hydraulic plunger breaks loose at TDC instead of 10 deg after TDC. The crank and cam timing marks are spot-on and the chain is new. I will retard the cam sprocket one tooth and try that. Does anyone have any experience with this issue?

Posted on: 2015/9/8 16:27

|

|||

|

||||

|

Re: a/c drive

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I'll ask my machinist...I think he's busier now than when he was actually working for a living, though.

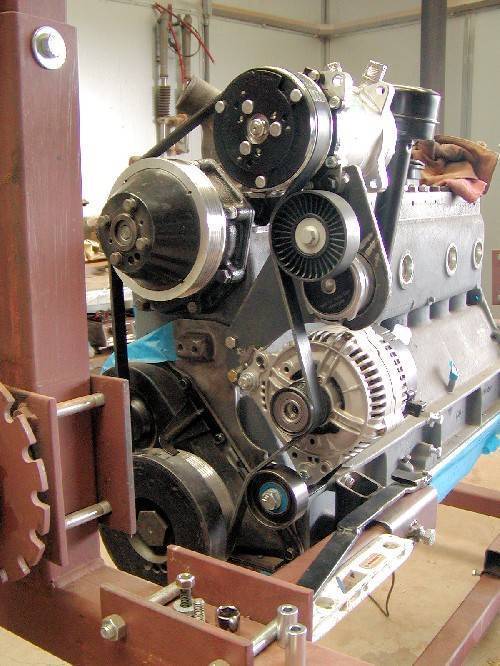

I'll be interested about alternator belt slip, too. My limited experience indicates that the alternator will be o.k. with about 60 degrees of engagement...maybe less. I will re-locate the idler pulley if there's a problem. Originally I'd planned to put the a/c compressor on one side of the engine and the alternator on the other but after trying several positions putting them both on the driver's side seemed to make the most sense. Even though the passenger side is relatively open the manifolds and fuel pump do cause some problems. Mike

Posted on: 2013/7/27 15:40

|

|||

|

||||

|

a/c drive

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I modified the crankshaft pulley and the water pump pulley to accept a serpentine belt. Providentially a friend here in S.W. New Mexico is a retired Boeing machinist and he did a marvelous job converting the pulleys.

The brackets were fabricated from flat stock steel and the idler pulley and tensioner puller were ordered from Jegs. We'll run the engine soon for a no-load break-in test but I expect no problems. (Famous last words, along with 'It seemed like a good idea at the time') M.

Posted on: 2013/7/27 12:55

|

|||

|

||||

|

Re: disc brake conversions

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Regarding the spindle bolt pattern...my parts book only goes through '54 so I can't look this up, but do the different models use a common part like the drum brake backing plate or the gasket or something like that?

In the '48 cars there is a considerable difference between the front spindles...but the bolt patterns are the same. (Now that I've said that, I better go look this up just to make sure.) Mike

Posted on: 2013/5/2 7:55

|

|||

|

||||

|

Re: disc brake conversions

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

The magic plate looks beautiful. What rotor are you using?

M.

Posted on: 2013/4/28 7:42

|

|||

|

||||

|

Re: disc brake conversions

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

The car is a 6-speed DSG automatic (I love it) and the pads had not been changed since new. The rear discs have 266 mm rotors and I think the fronts are 288 mm. The pads that came off the back were what ever the factory installed on them. Both the rear and front rotors are slightly grooved...I replaced the rear rotors without even trying to grind them to min. thickness.

I expected some wear on the front but they look like very little has worn from them...I didn't measure them, of course. The car has ABS, too. The braking system has functioned flawlessly since day one. M

Posted on: 2013/4/26 16:45

|

|||

|

||||

|

Re: disc brake conversions

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

James,

I just searched my e-mail 'sent' folder and found some communication with Kanter shipping...regarding the box in which the front end parts were shipped...NOTE: All questions were promptly answered regarding that situation...but I so far found nothing from me to Kanter regarding the brake issues. I'll now go out and see if I can find the Brake Invoice to pin the date down a bit. More later. Mike

Posted on: 2013/4/26 13:38

|

|||

|

||||

(135.15 KB)

(135.15 KB)