|

Re: Ultramatic

|

||||

|---|---|---|---|---|

|

Home away from home

|

Willis, HH provides a good description of what you should feel and the only thing I can add is that depending on the type of transmission fluid you are using, the converter lock-up can certainly feel different. I was concerned with my converter locking up and couldn't determine positive engagement with the Dexron II that the previous owner was using so I decided to drain it and refill with Ford "Type F" fluid and it made a considerable difference in the "feel" of the lock-up. After changing fluid I immediately began to feel both the lock-up and the drop off in RPM's which if I recall correctly was a fairly low number like 200 to 400 RPM's.

Posted on: 2013/10/10 7:05

|

|||

|

||||

|

Re: 21-23 radiator cradle isolation.

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard,

Not that it will be of any consequence but I had a '49 International KB-1 pickup that required the radiator support to be mounted very similar to your '47. IIRC, the support pad consisted of two 1-1/2" wide by 3" rectangular metal washers with two roughly 1/2" thicknesses of rubber "cushion" sandwiched in between the two washers. The washers and rubber pads all had a 1/2" hole thru the center for about a 1/2" X 2" carriage bolt to slip thru. This entire assembly rested on the front frame crossmember and of course the support rested on the pad. once the carriage bolt was installed thru the support, pad and frame, another round rubber "washer" similar to a thin shock absorber bushing was installed on the underside of the crossmember along with a flat washer. A lock washer was not used on top of the flat washer but instead, the carriage bolt was pre-drilled with a couple of staggered holes for a cotter pin/castle nut which finished the assembly. I assume the holes in the carriage bolt were staggered to allow for the amount of "crush" on the rubber pad. If this support is similar to yours, the carriage bolt shown with it also includes holes for the cotter pin/castle nut assembly. http://www.ebay.com/itm/47-PACKARD-RADIATOR-CORE-SUPPORT-BRACKET-BRACE-/140493600538

Posted on: 2013/10/3 19:06

|

|||

|

||||

|

Re: 1951 Packard parts car with AIR CONDITIONING

|

||||

|---|---|---|---|---|

|

Home away from home

|

I picked up my car from the same general area as where this one is located and it appears to be a pretty solid parts car. The AC and running gear parts alone could proove to be worth the haul and what appears to be good solid sheet metal is a bonus.

Posted on: 2013/10/1 7:22

|

|||

|

||||

|

The Self Parking Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

I've ran across a few short articles about Brooks Walker and his self parking '53 Packard Cavalier but missed this interesting November 2012 Old Cars Weekly article that went into more detail about it than any others I have seen with photos and details about the car's history, condition and ownership. Needless to say the car is a well preserved survivor based on the write-up.

http://www.oldcarsweekly.com/car-of-the-week/car-of-the-week-self-parking-1953-packard-cavalier

Posted on: 2013/9/28 23:24

|

|||

|

||||

|

Re: what goes here?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard,

I don't mean to change the subject but I'm curious about what appears to be a portion of a heat shield that was captured in the photos. Was a heat shield included on the 356 to help reduce the chance of a hot engine boiling the fuel in the carburetor bowl after it was was turned off?

Posted on: 2013/9/28 19:43

|

|||

|

||||

|

Re: Parts info for a 54 Clipper

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Post some photos of your new Clipper when you finish cleaning it up. You'll have a blast with it as a daily driver and you might even be surprised at how attached you get to it...

Posted on: 2013/9/28 19:28

|

|||

|

||||

|

Re: Windshield scratches

|

||||

|---|---|---|---|---|

|

Home away from home

|

I had some Turtle Wax polishing compound that I used to try and remove some scratch's out of my windshield. All were brought about by the windshield wipers and range anywhere from a light haze to a couple that will barely catch a finger nail. The polishing compound I used is far too fine to use by hand and I'm somewhat convinced that removing scratches from glass by hand is best approached by using several different grits of compound and graduating up from a more course compound to remove the scraches and then a finer course to polish. After placing a phone call on the subject, I came to the conclusion that the job is best left to the folks in the auto glass business who have the materials and experience to remove them a lot faster than I can for a price that became more reasonable with every minute of my wasted attempts but yes, light scratch's can be removed either way.

Posted on: 2013/9/27 16:32

|

|||

|

||||

|

Re: Flexible Fuel Lines and Fittings

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

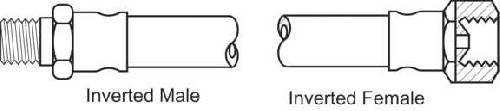

That's good information HH and I appreciate your providing it. It's sometimes difficult to go back and correct some modifications that other people don't consider to be important but engineers usually design things a specific way for a reason and I prefer to keep them that way when and where possible. What threw me was that the two AC fuel pump cores that I recently purchased had inverted flare 90 degree fittings for the hose to connect to the pump and in researching the subject, NAPA even showed their replacement hose with a a female inverted flare on the tube end and a male inverted flare on the pump end but like I said, the two fittings are close enough in appearance to easily confuse since the threads are the same. I just ordered a new flex hose from Then and Now and will wait to see what fitting they used for the pump end of the hose. if its 1/8" NPT then I'll connect it to the pump with a 90 degree NPT. Thanks Again.

Posted on: 2013/9/19 15:15

|

|||

|

||||

|

Flexible Fuel Lines and Fittings

|

||||

|---|---|---|---|---|

|

Home away from home

|

I had this posted under my original "AC/Blackstone Fuel Pump" heading but didn't think I would get a whole lot of response so decided to post as new topic. The fuel section of my AC fuel pump had been completely bypassed by the previous owner in favor of an electric pump. In that process, he had removed the fuel line fittings from the in and out ports on the mechanical pump and replaced them with 1/8" pipe plugs. That being said, I was left with guessing about how the lines originally connected to the pump. The pump to carburetor was a non issue, I found enough evidence through photos and other sources to confirm that the steel line connected to the pump via a 1/8" male NPT to 5/16" female inverted flare fitting. The main issue is with the flexible fuel line connection to the pump. In my research, I found enough evidence to suggest that there may have been two different fittings used on the pump as well as a possibility of two different flex lines. Whether or not Packard transitioned from one to the other is unconfirmed but apparently the available replacement flex lines can include either a 1/8" male NPT or a 5/16" male inverted flare fitting. The jest of the situation is that other than the male NPT threads being tapered and the male inverted flare fittings being straight, the fittings are virtually interchangeable. My guess is that there was a point in time when the flex line fitting that connects to the pump fitting was incorrectly identified which in turn required two different fittings to be used at the fuel pump. I'm just wondering what type of fitting others have used on the pump to connect the flex line.

Posted on: 2013/9/19 10:00

|

|||

|

||||

(8.73 KB)

(8.73 KB)