|

Re: How to troubleshoot my overdrive?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You'd need a toggle switch to manually engage the solenoid when at speed but there would be no damage. The issue might be when dropping out of OD because the timing between the kickdown switch closing and the solenoid contacts momentarily closing to complete the ignition drop out circuit would be dicy. You might not have the passing power at the instant you need it or the solenoid might try & drop out under load & not succeed.

Addendum: Looks like the issue is going to be finding a relay with 6v coil. Found any number of modern that would be satisfactory & might even fit into the can but only 1 with 6 v coil that can carry the amps. Its a mfg site and no info on who might carry for retail. Wonder if your coil actually open deep internally or maybe the wire connection might have opened close to terminals. Does it smell burned?

Posted on: 2008/7/4 18:41

|

|||

|

||||

|

Re: How to troubleshoot my overdrive?

|

||||

|---|---|---|---|---|

|

Home away from home

|

OK, the relay is on the bench and yes, the coil is open. I guess that answers that!

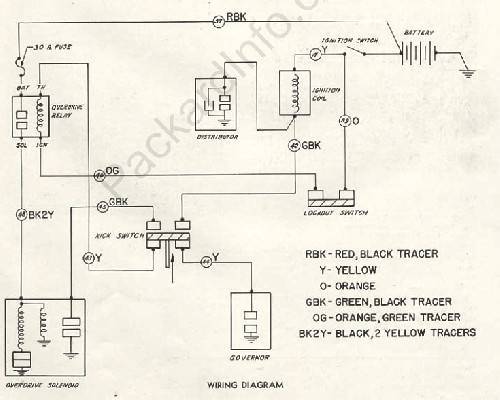

When I momentarily short the SOL wire to the 6v supply I can hear the solenoid click in. I checked the price of a replacement relay and it looks like $150. Ouch! I think I need to go shopping around a little bit and find a suitable replacement part. Anyway, I don't want to burn anything up. However it seems, from looking at the diagram, that I ought to be able to safely connect the solenoid wire to the fused 6v supply and have (likely) a working overdrive. Would you agree with that? Do you think that would work for a while? Jay

Posted on: 2008/7/4 18:11

|

|||

|

||||

|

Help. Pinion shaft torque spects

|

||||

|---|---|---|---|---|

|

Home away from home

|

I replaced the pinion shaft oil seal on the differential of my 51 300. The nut that held the yoke in came off with very little torque (too easy). I need help figuring out what to torque the nut back to. The book says to torque it from 300 to 325 foot pounds. This seems way too high. The book says to note the torque it takes to overcome the friction of the new seal and add 2 1/2 to 3 foot pounds too it for a total of say 4 1/2 foot lbs. This can't be the overall torque for the nut. I read it to mean the torque it takes to over come the seal drag plus the bearing friction after the torque on the nut is correct. There is no way to measure over all force to turn the pinion shaft that I know of without removing the rest of the universal and leaving only the pinion shaft in the housing.

Can Anyone help me? What should I torque the nut to if nothing else has been changed except the seal? Thanks, Bob

Posted on: 2008/7/4 17:25

|

|||

|

||||

|

Re: How to troubleshoot my overdrive?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Does sound suspicious. Here is the schematic so you can see that the relay coil is the only thing between the 2 terminals. Just for kicks you can ground the one not having voltage on it just to see if the relay will come in.

Looking at your first pict, it might not be a bad idea to remove and clean all the terminals up and maybe pop the cover and see what things look like inside.

Posted on: 2008/7/4 17:04

|

|||

|

||||

|

Re: 1930 packard parts PLEASE HELP!

|

||||

|---|---|---|---|---|

|

Just popping in

|

Hosie,

I would be interested in buying one or both of the window crank handles. They match the ones on my 1930 726. 726er

Posted on: 2008/7/4 16:53

|

|||

|

||||

|

Re: How to troubleshoot my overdrive?

|

||||

|---|---|---|---|---|

|

Home away from home

|

With the lockout switch shorted I now get 6v on ONE side of the relay (the right side, terminal NOT marked "SOL"). No voltage on the left side of the relay.

No voltage also on the kickdown switch, but FWIW I did do a resistance check and the switch is working (normally ON, with throttle OFF). Does this sound like a bad relay? If so, do you think it may be user-serviceable? That is, something I could try and accomplish?

Posted on: 2008/7/4 16:46

|

|||

|

||||

|

Re: Getting at instrument wiring???

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I lied on the 2 inches bit--actually closer to 4". As to leaving off, haven't tried but probably won't hurt if they are actually holes they fit into. If slots, wouldn't suggest it but you can always reinstall the nuts if there is a problem. I would expect a rattle so might suggest putting some kind of thick fabric tape or similar on bottom so cluster wouldn't be quite as loose down there.

Posted on: 2008/7/4 16:34

|

|||

|

||||

|

Re: Getting at instrument wiring???

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

HH56: Thank-you for pointing me in the right general direction.

Question: Once the nuts have been successfully found and removed by someone with very dextrous fingers, is it a mortal sin to simply not re-install them so that future access will require removing only the easy TOP screws? Or, will this lead to vibration and movement of the instrument panel? I'm asking because if the nuts are at the bottom of studs that extend DOWN from the panel, then the studs withOUT nuts should still locate the panel's bottom edge, and the TOP screws might be sufficient to prevent vibration? Jim G

Posted on: 2008/7/4 16:14

|

|||

|

||||

|

Re: How to troubleshoot my overdrive?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thanks, You learn something new every day!

Posted on: 2008/7/4 16:13

|

|||

|

||||

(38.45 KB)

(38.45 KB)