|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

I can not thank you guys enough for doing this! saved me a lot of hassle!

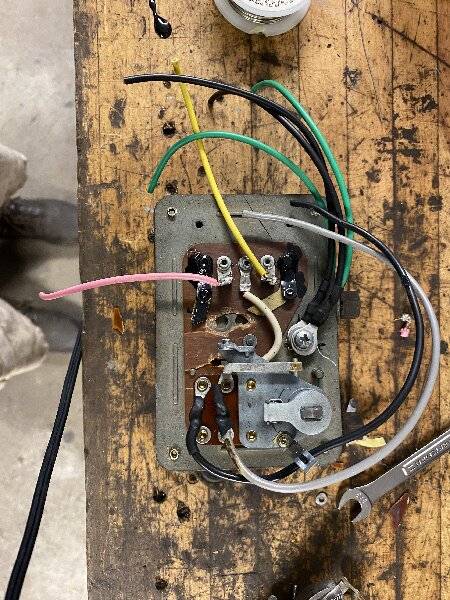

I did do something a little different. Howard is correct in that you NEED a powerful solder gun. Mine was nowhere near the 200W like he suggested, and the ones at work only went up to 140W. But I found another way: so since your modifying the switch to the point original parts would no longer work, I cut one side of the contact that the relays would interact with and hammered out the other side. Doing so created a hole on top of that "L" contact. From there I wrapped the wire into that hole and around the top of the contact and a regular soldering iron was able to solder it properly.

Posted on: 2023/6/23 8:42

|

|||

|

||||

|

Re: Vacation Car - 56 Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well, the entire front suspension is done! Disassembly wasnt difficult. I left the backing plates, and associated brake stuff on the knuckle and just removed the pivot bolts. The upper and lower control arms came out fairly easily. Upon disassembly I finally understood what my dad meant when he rebushed the car, he only did the control arm bushings.

pressing the bushings out of the upper arms were not bad at all. Pushing them in was a little tricky but it went together A okay. I saw that a lot of people cut apart the lower control arms to get the bushings out, but with a punch and a decent size hammer they came right out. Again pressing them in was a little tricky, but got it done. once the suspension was together, torqued at ride height I went on to installing the power steering hardware since my dad converted it to manual steering. Everything went together on the underside okay until I saw the power steering cylinder was hitting the exhaust. After doing some research I saw that the stove valve for the exhaust was installed on the wrong side, so once it was installed on the drivers side, it all went together okay. I took this time to change the cross(?) shaft seal on the bottom of the steering gear. I was a little annoyed that I had to partially disassemble the gear to change it, but I am glad I did. it was bone dry... No idea for how long, but I cleaned up the components, added the new seal and coated everything with a liberal amount of oil. I was letting everything sit before I fill the steering gear up. Surprisingly I had a little extra time that I utilized to reworking 1 and almost two leverler control switches. Not to bad to do. Once I test fit the alternator Ill install the generator hook up the new switch and report back on how well it works on the car.

Posted on: 2023/6/23 8:32

|

|||

|

||||

|

Re: Resurrecting my 56’ Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

What did you use for tires? They look like they are brand new?

Posted on: 2023/6/19 10:34

|

|||

|

||||

|

Re: Vacation Car - 56 Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

I dont blame you on that. I would have gone that route, but the door cards appeared in presentable shape and I wanted everything to match. Hopefully the seats dont make the door cards look too bad, but only time will tell. thanks Riki! Ill keep that in mind But as for an update, last week was busier than all hell, but I was able to get the entire rear suspension disassembled by having the car up on jack stands via the frame, put the axle on jack stands and just unbolted everything. I put a hydraulic jack under the load arms as the U bolts were undone and just lowered the load arms via the hydraulic jack once the U-bolts were undone. I did grab pictures of the U-bolts with a measuring tape just in case anyone would need to find new ones in the future. but I got it all painted, rebushed, assembled, torqued and back on the ground! I hope to start on the front this weekend. Everything appears to be straight forward, I have the holding tool for the torsion bar. is there any cutting that needs done to get the old bushings out? and do I really have to remove the backing plates from the steering knuckles/spindles? or can I just remove the knuckles/spindles by removing their pivots from the upper and lower control arms leaving the backing plates and brakes on? Besides taking pictures during disassembly so I know how it all goes back together, anything else I should be aware of? thanks!

Posted on: 2023/6/6 16:58

|

|||

|

||||

|

Re: Vacation Car - 56 Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

So I had to get some work done to my truck before the summer got into full swing, so now that is done I am back to focusing on the Patrician.

Got word that the carpet should hopefully ship in 2 weeks... hopefully. Been waiting a couple months for it. last I heard on the seat covers is that they started it, ran out of material, created more material... I am due to follow up with them soon. Didnt get a chance to modify one of my control switches to what Howard created. hopefully soon. I did start on re-bushing the rear suspension. I got mostly everything disassembled, going to try and get the big nut off of the front of the load arm tonight. Game plan is to have it disassembled and paint tomorrow and spend the holiday weekend getting the suspension back together.

Posted on: 2023/5/26 16:20

|

|||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Thank you so much for this!! this is amazing!! when I finish maintenance up on my truck I will try this mod!!

Posted on: 2023/4/24 12:45

|

|||

|

||||

|

Re: Vacation Car - 56 Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Yes I can wait! The fact that I know what needs done is a big weight lifted off my chest. The next step for this car is replacing suspension bushings that I hope to start in the next week or so.

Posted on: 2023/4/18 12:12

|

|||

|

||||

|

Re: Vacation Car - 56 Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Okay, so I found this simple timing circuit: http://www.learningaboutelectronics.com/Articles/555-timer-delay-before-turn-on-circuit.php So the trigger would be from the rotating arm letting the switch know the car changed positions. Your input voltage would be from the green wire that is controlled by the dash switch. Your output would be going to the relay. Now how does the relay work (wiring it up) sending the ground signal to the limit switch?

Posted on: 2023/4/18 9:29

|

|||

|

||||

|

Re: Vacation Car - 56 Patrician

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Quote:

This is all wonderful information thank you!! so if I want to get one of these working I got to start working on getting Box two fixed by finding out why the yellow terminal is always going to ground. R H, that doesnt look to bad to replicate. I can try and do something like that if you dont have the time and dont mind sharing the gerber file, wiring diagram, and component information.

Posted on: 2023/4/17 10:02

|

|||

|

||||

IMG_1894.jpg (369.66 KB)

IMG_1894.jpg (369.66 KB)