|

Re: 1951 288 - Head and Manifolds - Nut and Washer Grades

|

||||

|---|---|---|---|---|

|

Home away from home

|

Regarding Max Merritt, I'm expecting their hardware will need to be painted but I'll ask. I'm not going to paint the nuts/washers after I install the head. I don't think I want SST either.

Posted on: 7/24 20:12

|

|||

|

||||

|

1951 288 - Head and Manifolds - Nut and Washer Grades

|

||||

|---|---|---|---|---|

|

Home away from home

|

Bottom Line Up Front: Can I use grade 5 washers and grade 8 nuts for the head and manifolds?

I have removed the head and manifolds. They have been sandblasted and will be resurfaced, primed (2000 degree) and painted (1600 degree). Since the nuts and washers will not be painted I'm thinking of using black oxide (900 degree). In black oxide, I have found grade 8 nuts but only grade 5 washers.

Posted on: 7/24 17:38

|

|||

|

||||

|

Re: Looking for a radiator

|

||||

|---|---|---|---|---|

|

Home away from home

|

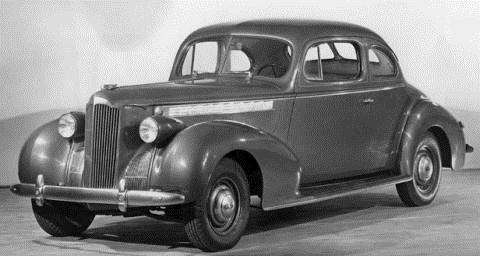

I have a 1951 288 in a 2498 business coupe with an Ultramatic. I measured the radiator including the input and output. I matched these dimensions with the data at "Find a Radiator By Core Size (H x W)" athttps://shop.championcooling.com/index.php?route=product/coresize .

I determined that the radiator used in a 1955-1957 GMC truck was almost an exact fit. I bought one for $138. I bought some 1" square and 2" flat aluminum and adapted the mounting. I spent about $160 altogether. Otherwise it was going to cost me over $2,000. I would have been scared to work anywhere near it.

Posted on: 6/28 18:10

|

|||

|

||||

|

Valve Seat Grinding Tool Set

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'm going to buy a valve seat grinding tool set.

1 1/2" for 1 7/16" exhaust? 1 3/4" for 1 43/64" intake? The sets that are readily available and reasonably priced do not include a locking pilot. Is this an issue?https://www.ebay.com/itm/225042095012 11/32" locking pilot shown.https://www.ebay.com/itm/176379809756?chn=ps&mkevt=1&mkcid=28 I believe the pilot upper diameter needs to match the handle inner diameter. Excellent valve seat grinding video shown at following link:https://www.youtube.com/watch?v=la4Kfl2H590

Posted on: 6/26 9:41

|

|||

|

||||

|

Can someone give me a source/part-number for 1951 head and manifold paint?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Can someone give me a source/part-number for 1951 head and manifold paint?

Posted on: 6/11 17:57

|

|||

|

||||

|

Re: How do I measure how much can be milled off 1951 288 head?

|

||||

|---|---|---|---|---|

|

Home away from home

|

I guess I didn't describe my situation properly. I don't know if the head has been milled before. I don't know if it needs milling, I will have the machine shop measure the warp, if any. Hopefully the shop can tell me how much, if any, needs to be milled. I'd like to know if that much can be milled. I'd think that would be based on measurements of how deep the cylinder cavities (combustion chambers) are. In other words, are the cylinder cavities deep enough to clear the protrusion of the valves above the block.

How much warpage is tolerable for a 1951 288? I've read that flatheads are more accommodating of warpage than overhead valve heads because the flatheads will flex. Also, copper head gaskets are further accommodating.

Posted on: 6/5 22:34

|

|||

|

||||

|

1951 288 Packard Valve Clearance Notes: What is the minimal clearance?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Measurements below are at cylinder 2 prior to surfacing.

Highest edge exhaust valve above block: .3475 Head surface plus straight edge to cylinder cavity: .4945 Straight edge: .0750 Used head gasket: .0600 Clearance with straight edge: .4945 - .3475 = .147 Clearance with used head gasket: .132 Minimal clearance: ?

Posted on: 6/4 11:35

|

|||

|

||||

|

Re: What metal nuts/washers for head and manifolds?

|

||||

|---|---|---|---|---|

|

Home away from home

|

I would use Grade 8 also except I'm thinking stainless steel.

Fromhttps://www.stsindustrial.com/products/grade-8-stainless-steel-heavy-hex-nut-domestic/: "Grade 8 SS Heavy Hex Nut Domestic Domestic ASTM A194 Grade 8 heavy hex nuts are manufactured from AISI 304 grade stainless steel, tested to meet ASTM A194 Grade 8, and are melted and manufactured in the USA. Dimensional specifications are governed by ASME B18.2.2. Grade markings for A194 Grade 8 heavy hex nuts consists of the number 8. Grade 8 stainless steel heavy hex nuts are intended for use in high-pressure and/or high-temperature service with ASTM A193 bolting of similar material, such as B8 and B8 Class 2. Heavy hex nuts provide increased bearing surface area over finished nuts." It sounds like in other words, 304 is equivalent to Grade 8. Any thoughts?

Posted on: 6/4 11:12

|

|||

|

||||

|

How do I measure how much can be milled off 1951 288 head?

|

||||

|---|---|---|---|---|

|

Home away from home

|

How do I measure how much can be milled off 1951 288 head? I'd like to do this before paying to have it milled and then using clay. I'd use clay to verify. How much do the valves rise above the block? I'm going to try to measure and will post. Will also try to measure depth of cylinder cavities in head and post. I have 2 dial indicators but need a mount.

Posted on: 6/4 7:00

|

|||

|

||||