Home away from home

Joined:

2023/9/1 8:20

Last Login

:

Today 6:58

Group:

Registered Users

|

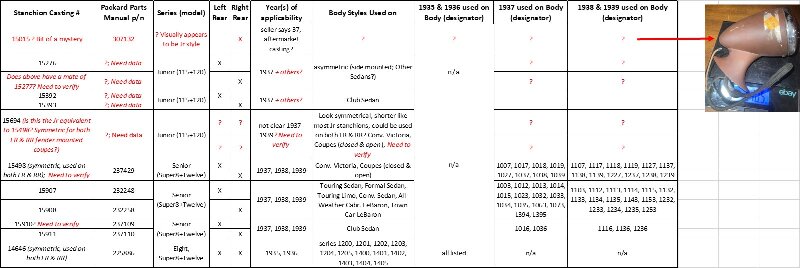

NOTE: known 1935/1936/1937/1938/1939 info provided, but not fully validated)

OK, Packard Guru's: please compare your knowledge, physical stanchions mounted-on/spares from your actual vehicles, notes/knowledge and please cross-check my work; I can't submit this to writers like R. Supina for inclusion into a book without some "scholarly" validation/cross-checking by some other experts. I backchecked what I could on units/vendors for sale, visual inspections of cars/stanchions, master parts list references/notes and talked to several "Yoda's" in the Packard world.

Please post known errors, "it looks correct compared to my _____ model ____ year vehicle", or recommended edits; I am a Senior model guy and would appreciate an expert in Junior series to provide the parts manual #'s & cross-checks; I only know about Junior parts because my Senior came with some cobbled up assys of a mix of both.

A) Since the design styling dept. dictated a bunch of different body styles, and the engineering dept. controlled the company (good most of the time), it is no surprise why Packard had profit margin struggles over the years looking at the variety of unique line items that werent standardized

B) All 1937 series, Jr & Sr, used the same tail light "body" (aka "can" or "bucket") which was a spinned-steel geometry "torpedo" shape

C) Jr cars attached a "flatter" all red lense and a more "squarish" profile chrome trim bezel to this

D) Sr cars had the "bullet" convex-shaped (with center "jewel" dot) lense and a slightly higher profile "curved" chrome trim bezel

E) The taillight stanchions were different based on the body style curvature (design styling dictated the outer mold line of the vehicle) to ensure the taillights pointed directly rearward (stanchions adapted the body mold line curvature to the tail light body)

F) Generally, the coupes (including both closed and open styles) with their lower curved rear "boat" type sloped rear ends/fenders had the tail lamp stanchions attached to the fenders, whereas the sedans had "body" mounted stanchions (90 deg attachment) near the boot lid zone

G) A general quick visual characteristic is that the very forward tip of the Junior Stanchions are about "flush" with the pointed front tip of the tail light bucket; the Senior Stanchion forward tip is much farther forward than this pointed tip of the bucket giving a much longer streamlined appearance/dimension where the stanchion attaches to the body or fender

H) Packard parts manuals list the in-house engineering part number; the stanchions were subcontracted to vendors (Alemite, Hall Lamp, Michigan die casting, etc) and what is embossed in the pot metal casting is a component/part casting number. The casting number is subsidiary to the engineering part number and never was listed as an individual element in the parts manual...Nance had all the low-level subcontract manufacturing records destroyed in the 50's ("out with old in with the new" Packard transformation moving out of the Grand blvd facility)...thus creating an elusive mystery. Dick Teague was responsible for quietly instigating, amongst the design staff, a year-long "extraction" of many original drawings that still survive, but crossover manufacturing records (like the stanchions) were too numerous and were the sacrificial lambs.

I) So, the following table is my reconstruction attempt to help all the restorers of mid-late 30's Packards:

Attach file:

35-39 Packard Tail Light Stanchions_11_1_23_RevDRAFT.jpg (212.00 KB) 35-39 Packard Tail Light Stanchions_11_1_23_RevDRAFT.jpg (212.00 KB)

Posted on: 2023/11/1 12:52

|