|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

talk about rust out early in a cars life, I had a 77 Plymouth Valore I bought new and the front fenders rusted out in a year. The factory replaced them but the new ones also rusted out in a year. They refused to replace the second set.

Posted on: 2014/4/1 22:20

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

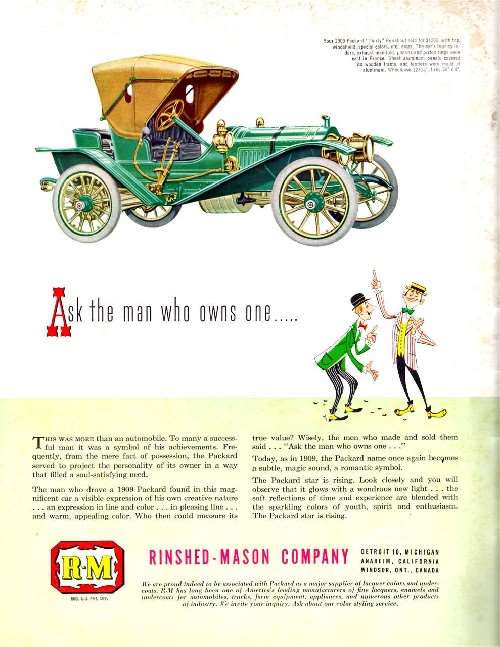

Curious - I don't think Rinshed-Mason as Packard's major paint supplier has been once mentioned on here in a decade, and suddenly it's mentioned twice.

I sure agree with Leeedy about the quality of those nitrocellulose paint jobs; properly done and given care and avoiding the worst elements they can survive splendidly for 80 or more years. As many of you know most the paint on my 34 is original and good enough for 92+ points at a CCCA Grand Classic a couple of years ago. First failures are normally crazing over the lead joints and I'm beginning to get a bit of that. The major lead joints are quite large in area and are where the 4 steel panels are joined to form the roof. The 4 fenders and hood were repainted by me many years ago with Rinshed Mason nitrocellulose lacquer and fortunately I have enough left to do some spot repair on the roof areas if they become worse.

Posted on: 2014/4/1 22:35

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

In our family fleet of mostly GM light trucks and SUVs, the very worst part about these otherwise long-lived vehicles (400-600,000 miles) is the adherence of the water-based paints. Since most of ours are white, the paint will lift off of the zinc-coated panels in patches, leaving the gray primer showing. Then the vehicle has to be stripped if any new paint has to adhere. Somewhat strangely, the darker colored vehicles have had very little paint lifting and some of them are approaching twenty years. Then again, having moved south almost thirty years ago, everything seems to last much longer than our times in Minnesota, Illinois, Missouri and Maine. When we see the "snow birds" come south in their fairly recent Chrysler minivans and SUVs, I am horrified at the toll taken by the salted roadways in the form of surface rust and perforation. I thought that newer cars were warranted for ten years against that sort of damage. Is nothing being done to pay those claims, or is it just another bonus for the pleasures of living north?

With regard to Packard paint and rust protection, my 56 still looks good with the 45 year old Duco respray. However, looking good is not all it's cracked up to be. The front inner fenders around the radiator have mostly rusted into oblivion, and the inner rocker panels are doing the same, albeit more slowly. New parts are in my future, should I be able to find them. Since this car was used for its first twenty in Virginia where I remember salt and sand, I will blame that on the roads instead of Packard. As my Corvette friends would say when it came to frame rails rusting, GM never intended these cars to last more than 5-8 years when they were produced. Having 58 years, or even O-D's 80, out of a Packard, is saying something more to the care than to the car.

Posted on: 2014/4/2 7:49

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Hello... I have certainly mentioned R-M numerous times in connection with Packard. In fact, if you go back to my article in Car Classics magazine (December 1978) on Creative Industries, I quote a friend of mine, Gary Hutchings, who worked for Creative on the Panthers and on the Packard Request. In this quote I mention how Creative made the white pearl paint that was used on The Request, Rex Terry's black & pearl white Panther and on the Predictor. That paint was mixed by Creative, but supplied by R-M. When people today on the internet are talking about Creative and the connection with the Packard concepts, they are usually (whether they realize it or not) merely parroting back the information in that article. I also re-discusssed R-M and Packard Pearl White on The Request and Predictor in The Packard Cormorant magazine, (Summer, 2008 issue) in my history of the Predictor. So perhaps R-M has not seen mention in this internet forum, but it certainly has been mentioned in print in connection with Packard many times. R-M was also mentioned in industrial magazines that covered the new Packard Conner Avenue Plant... and there were several of these. R-M also ran big ads talking about how it supplied Packard. However, as I said earlier, I believe Ditzler also supplied some paints (lacquer) to Packard. Also Du Pont (Duco) certainly had all formulas and color chip sheets for Packard going well back into the 1930s in my records. Du Pont issued color chips and formulas for Packard well into 1956. It is rather amazing to look at color chips from the 1930s and then compare them to those issued for V8 Packards... kinda..WOW! Finally... in the old days of Detroit when the Packard Plant on East Grand Blvd. was still producing cars, if you drove past the plant heading west, then turned north (right) on Mt. Elliot you would eventually come to the split of Mt. Elliot and Conant Avenue. Somewhere up that way I remember to the right was a stamping plant and a huge outdoor fenced area there hundreds of thousands of black painted car chassis were stacked... row after row, column after column. An amazing sight if there ever was one. There was always a hum in the air-day or night... people working... making good salaries while they were making cars. And there always was the heavy fragrance of fresh automotive paint in the air, especially the sweet smell of nitro lacquer. Like someone once said about Los Angeles, you could smell it before you could see it. Anyway... eventually along here was a huge overhead enclosed bridge. The sides were painted in brilliant colors (I remember a lot of orange) and it was illuminated with floodlights at night. It said..."RINSHED-MASON"... which my little cousin back then proudly referred to as "rinsed mason." I sure miss it all.

Posted on: 2014/4/2 15:12

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

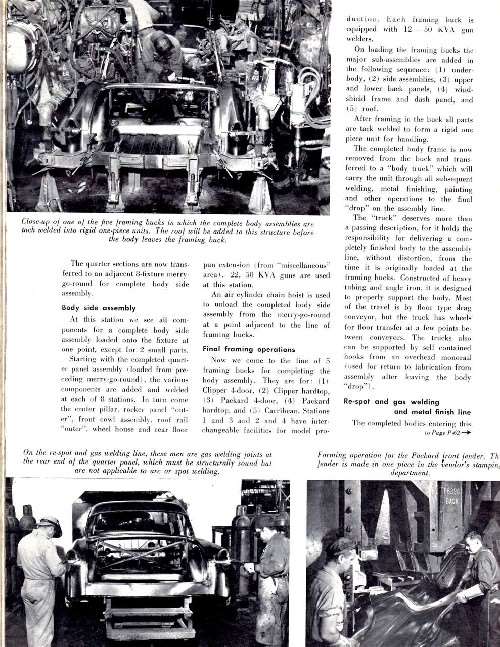

From the February 1955 "Special Packard Section" of Finish the magazine of metal products manufacturing

Posted on: 2014/4/2 17:04

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Yes, these are Page P-48 and the color inside cover of the Special Packard Section from Finish Magazine of February, 1955.

Elsewhere in the same section you will find a full page advertisement for Parker Rust Proof Company on Page P-57. This company provided a special primer called "Bonderite" for both Studebakers and Packards. By the way, this section talks in detail about and shows the entire metal prep and painting process for 1955-56 Packards and Clippers.

Posted on: 2014/4/3 12:22

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Have to find my copy.

It says that they built the Caribbeans, I thought I had heard it was done someplace else, or do I have that mixed up with the 53-54 Caribbeans?

Posted on: 2014/4/3 14:00

|

|||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Elsewhere in the same section you will find a full page advertisement for Parker Rust Proof Company on Page P-57. This company provided a special primer called "Bonderite" for both Studebakers and Packards. Apparently no one today remembers what rust buckets these cars were in the day. I bought my first Packard in 1959. By then all the Packards were on the last row of the lot, and all lacked rocker panels and most had other rust related issues. I finally found a 1956 Patrician in good shape, for which I paid $550. Much as I ;liked the interior, the headlight area had pinpricks, as did the rockers. the door bottoms were suspect as well. And we all remember Studebaker front fenders and the lack of a proper interior splash guard. Bonderite must have been associated with bondo, another fine product of the era....

Posted on: 2014/4/3 16:18

|

|||

|

When two men ride the same horse, one has to be in the back...

|

||||

|

||||

|

Re: How'd they do it?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

For one, I remember these cars very, very, very well. I lived around them, watched them grow old, owned more than I want to count, and like I said previously, I can think of so many other cars that out-rusted these Packards. I lived in Detroit... grew up there. I knew real rust! I had a cousin in Detroit who swore that Nash had the best bodies when they went to unit body construction. He kept his opinion... until the rear suspension on his car came right up through the floor and the trunk one day, locking up the rear tires in the wheel wells! Even IF Packards were parked at the end of the used car lots in 1959...at least they were ON the lot! I also had an uncle who argued that Buicks and GM cars had the best rust resistance... until one day when we were headed in his Roadmaster out to Hines Park for a picnic (old Detroiters ought to know this location). We hit a good-sized bump in the road and two melons sitting on the rear floor went right through it ...and ejected out behind the car ... exploding like WW2 depth-charges off the back of a Navy ship! And speaking of GM's supposed great resistance to the elements, we also bought two brand-new 1955 Pontiacs. Assure you... one of them never made it to the good 'ol used car lot by 1959... mainly because it wasn't drivable past our garage! Much of that reason was you know what! AND the other car was a wagon. Wanna know how many times yours truly had replaced totally rusted tailgate cable reels by 1959? Hmmm??? By the way, these little gadgets were only reached from inside the vehicle... but they rusted like they had been dragged up from the ocean bottom by a deep-sea trawler! I already gave the example of my aunt's brand new 1957 Plymouth that rusted out (swiss-cheese kinda rust) in less than 16 months! AND.. if it helps any, my family were also die-hard MoPar folks-so this isn't anti-MoPar bias talking. One uncle helped set up a new Chrysler plant in Ohio and retired from Chrysler. My cousin (son of the aunt in question here) also retired from Chrysler and worked at one point with Packard aficionado and fan Marv King. Ask Marvin. I'm sorry, but if a new Packard out-rusted my aunt's new 1957 Plymouth, I would LOVE to hear the story and see some pics. RE: "Bondo"... No. Bonderite and Bondo were two different things-the first a primer, the latter a body filler. However since we're making fun of Bondo and whether people can remember things, let us not forget that Packard invented a type of Bondo. Remember THAT? It was officially known as "Packard New Metal" and was (at least for a time) considered an advanced new kind of replacement for lead. And for anyone still laughing... wanna know what they used the stuff on at the factory??? 1955 Caribbean hoods. But that's another story for another time and place.

Posted on: 2014/4/3 21:04

|

|||

|

||||

(141.41 KB)

(141.41 KB)