|

Re: 1928 Front End Shimmy

|

||||

|---|---|---|---|---|

|

Home away from home

|

Gar

Advanced Search with "Technical Letters" as Keywords, and only the technical/service sections checked. A list will appear . . . at the bottom is "Show All Results" . . . click that choice At the bottom of the next list is "Technical Letters" . . . click that choice A listing of TLs will be displayed . . . scroll until 1840 . . . click that choice This link might work: https://packardinfo.com/xoops/html/downloads/TechLetters/TechLetter-1840.pdf dp

Posted on: 2022/8/17 14:42

|

|||

|

||||

|

Re: Need ‘40 super 8 generator over night

|

||||

|---|---|---|---|---|

|

Home away from home

|

Most, if not all Model A parts houses will have 6 volt positive ground alternators based on a Delco 10SI. They will also have a sheave already mounted for a wide belt, but I would avoid using the smallest diameter available, because the Ford has an especially small engine pulley, and the engine operates at a low RPM.

Posted on: 2022/8/11 22:09

|

|||

|

||||

|

Re: Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Home away from home

|

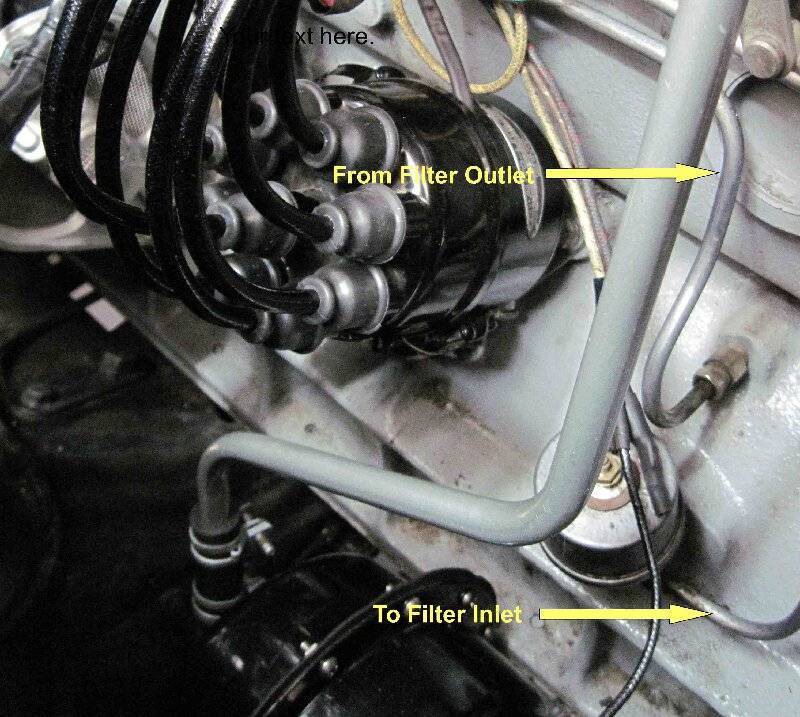

Packwagon;

Packard used what I consider a unique lubrication schematic when it came to the tappet gallery. Unique because the oil destined for the tappets was routed external before being directed back into the block. Given that engines with hydraulic lifters benefited from filtered oil, the oil filter was plumbed ‘in series’ with this external circuit. Later the subject of poor lifter performance when the filter became restricted was resolved by plumbing the filter as a pure partial flow device where the discharge of the filter was routed directly to the oil pan area. All engines placed the oil pressure sending unit in the external tappet gallery plumbing. I believe there was some advice from Packard on how to convert an early engine block to the later design that routed the filtered oil to the pan. Given that most of us pamper our cars, the issues that resulted from ‘under maintained’ oil filters are not likely to reoccur, plus that issue was only for the hydraulic tappet engines. I also question the sensibility of directing some fraction of the oil pump capacity just to filter the oil . . . not that filtration isn’t important, but I would prefer to use the entire oil pump capacity to lubricate the engine. There will be a short piece of tubing connected to the upper tappet gallery fitting . . . that’s the one that’s removed when installing an oil filter (step 4 in the instructions). Think about the direction of the oil flow, which is from the lower port on the engine block to the upper port on the engine block. You connect the lower port on the engine block to the upper port on the oil filter (note step 2 is defining the side port on the filter as the ‘INLET’). You then connect the lower port on the oil filter (marked ‘OUTLET’) to the upper port on the engine. See attached photo . . . it’s a 22nd series 288. dp

Posted on: 2022/7/30 20:52

|

|||

|

||||

|

Re: Resurrecting a 1951 Henney-Packard Parts Car

|

||||

|---|---|---|---|---|

|

Home away from home

|

Don;

Here's a link to an OD teardown. http://devestechnet.com/Figures/bwrebuild.pdf By the way the 'missing' snap-ring was an item used on BW units in Lincoln, Mercury, & Fords, else not used. dp

Posted on: 2022/7/28 17:38

|

|||

|

||||

|

Re: 1928 Front End Shimmy

|

||||

|---|---|---|---|---|

|

Home away from home

|

Gar;

In the ’29 service manual page 221, there is a ‘cut-away’ of the front suspension and steering knuckle. That graphic suggests the Packard ‘Steering Knuckle Pin’ features ball bearings that require some type of shimming. The adjustment procedure is on page 222, procedure S119. The material call-out mentions shims of 0.005” or 0.025” thickness. All of this suggests either a minimum vertical motion or bearing pre-load is being set. I’m significantly out of my league with that design . . . I’m strictly from reamed Bushingville, with a simple thrust bearing to support the weight of the car. The note in S119, step #5 suggests a check should be made to ensure the bearings have not been pinched with excessive preload, therefore if you use the procedure to check the bushing design a near zero ‘looseness’ would be expected. The contents of Technical Letter 1840 (referenced in S119) may contain the missing pieces, but I’ve been unsuccessful finding that document. Assuming this site has a copy, I think I need HH56’s site navigation skills. Update: I finally found TL 1840. I'll look it over for some insight on the adjustment "do's and don'ts". Seems the bearings were being ‘pinched’ in the field by not shimming correctly (still no insight on the correct procedure). The fix was a different plug, and two Belleville washers to replace the stack of shims. Seems the new plug could be made locally by machining the original design. All of that detail tells me the bearings were designed for a preload (zero slop), but the field exceeded the desired pre-load while maintaining the cars. Gar, download a copy of Technical Letter 1840 and measure your cap against the 13/32 dimension called-out in the letter. If it’s 3/16 longer, then you have the original design. Still no idea of the Belleville geometry. dp

Posted on: 2022/7/17 20:08

|

|||

|

||||

|

Re: 1928 Front End Shimmy

|

||||

|---|---|---|---|---|

|

Home away from home

|

Ernie: English is such a wonderful language, is the adjective ‘old’ modifying the noun ‘car’ or the noun ‘dude’?

As for the genealogy . . . My grandfather, along with his lodge mates, commissioned a publication (circa 1920) to document the various ‘family trees’ of the lodge members. The entries for my grandfather and James & William (of the motor car company fame) read eerily the same. Their ancestors immigrated in the same time frame, and had the same debarkation and destination points as those identified for my grandfather. I just don’t remember if Samuel was a common starting point. The only difference that I can tell is my branch of the Packard clan stayed close to what is now Massachusetts, while others went west (I guess just about every place is west of MA, sorry to those in ME, NH, and VT). While I now live in Arizona I still consider myself as part of the Massachusetts clan. I remain skeptical as to being a direct relative, and rest assured, if I am related, I don’t get a family discount. By the way many versions of the family crest do not feature the retched bird. I know from the native population perspective those damn Packards came ‘without papers’. Gar: The motion that Ernie is suggesting you look for is transient, meaning if the spring needs more preload the lost motion only occurs until an adequate amount of spring force is achieved. The lost motion is only at the very beginning of steering wheel rotation. Most of these systems are designed such that when the steering wheel is controlling the motion one joint will be ‘hard’ (meaning the spring is not in the load path), and the wheel will be in motion as soon as the linkage moves. On the other side the joint is ‘soft’ (meaning the spring is in the load path) and the wheel motion will be delayed until the spring force can overcome the friction between the ground and the tire. Ernie is right, finding that motion on a lift will be difficult. On to the steering box: The straight-ahead position of a steering box typically wears a bit more than anywhere else (that’s small area on the worm and sector gears when the car is traveling straight-ahead). Assuming the ’28 steering box is adjustable, the straight-ahead position is typically adjusted for the minimum ‘slop’, but as the wear increases this adjustment may create a bind at full lock (the position where there is minimum, or no wear). I would jack the car up and slowly rotate the steering wheel lock to lock trying to feel if there is gear binding at the limits of travel. If you have good straight ahead feel and binding at full lock, you might want to adjust and put a little ‘slop’ at straight-ahead, (likely the sector gear mesh adjustment) and recheck the end points. My bet is you’ll want the least amount of play straight-ahead, and if the steering wheel needs a bit of persuasion to leave the full lock position . . . so be it (that's the way I have Brand X adjusted). Steering boxes that have multiple adjustments require an iterative process, because one adjustment can affect the other. Now the question is whether the ’28 Packard steering box has service adjustments s for bearing clearance and selector gear mesh. In the ’29 service materials (available on this site) on page 231 there is a photo of the steering box, and on page 232 there is an adjustment procedure, step 1 looks like the worm bearing adjustment, step 2 looks like the sector bearing adjustment, while step 3 looks like the sector gear engagement adjustment. The photo on page 231 does not show the eccentric bushing called-out in step 3 of the procedure. So are the ’28 & ’29 steering boxes ‘about the same’? dp

Posted on: 2022/7/14 20:03

|

|||

|

||||

|

Re: Mike P 1955 400 Slow Resto Thread!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Mike and I have had several PM conversations about Daytona style fuel valves (aka needle & seat). I initially concluded Daytona was using extra gaskets to achieve the desired float level. While that may still be correct, my understanding now is Daytona makes valves of a particular height, and that height is not necessarily the height of the OEM valve, which is a critical characteristic in the float level determination/adjustment. To achieve the OEM valve height Daytona uses up to 3 fuel valve gaskets where the OEM uses 1 gasket. Dayton also acknowledges that their valve may not need additional gaskets for non-Carter applications as in Mike’s case. I surely missed the point that Mike had a Rochester unit.

The following are the instructions included in the packaging of the Daytona valves: FLOAT VALVE GASKET INSTRUCTIONS To maintain correct needle & seat height, use the following RECOMMENDED guide to install the close tolerance gaskets in this kit. CARTER APPLICATIONS, use 3 gaskets ALL OTHER BRANDS, use 1 or 2 gaskets If a valve is installed that is substantially shorter (measured from the gasket surface to the end of the needle) than the OEM valve the float tang adjustment will be beyond the intended range and will likely apply a side load to the needle. Since the Daytona specific instruction come separately, the general instruction set that comes with carburetor kits will not necessarily mention those instructions. Those of us that use a Daytona style valve(s) in our Carter carburetors should be aware of the supplementary instructions, and when in doubt as to the number of gaskets to use a measurement from the gasket sealing surface to the end of the needle will be the determining factor. My guidance of ensuring the float tang is pressing on the center of the needle when the valve is closed is likely valid. dp

Posted on: 2022/7/11 15:44

|

|||

|

||||

|

Re: Mike P 1955 400 Slow Resto Thread!

|

||||

|---|---|---|---|---|

|

Home away from home

|

When setting the float level the Daytona valves use a different technique versus the OEM valve.

To achieve the correct float level with an OEM needle and seat a tang on the float is bent/adjusted. For the Daytona valve the float level is set by shimming the seat with more gaskets. At the closed position the tang on the float should contact the Daytona needle as close to the center as possible. If the tag presses off center by a significant amount there is a possibility the needle will be pushed into a cocked position that will be beyond the capability of the compliant flat disk. Daytona covers this in the instruction set, and if you follow the instructions the valve will work as advertised. Shimming the seat of the fuel shut-off valve to achieve the correct float level is not a new invention, it goes back something like 100 years. dp

Posted on: 2022/7/7 22:13

|

|||

|

||||

|

Re: 1928 Front End Shimmy

|

||||

|---|---|---|---|---|

|

Home away from home

|

Does the ’28 Packard use a steering linkage design that features an internal spring and a threaded plug to establish the tightness of the drag link and/or tie rod end?

29tons posting brought back memories; my library of manuals extends only back to the late 30’s and by that time the Packard tie rod ends appear to be quite similar to the ones we have today, but the drag link was still the adjustable design. My Brand X (’30 Model A) has the adjustable design at every joint and those cars will occasionally ‘shimmy’ (aka death wobble), which is quite an adventure! Re-setting the spring tension always seem to solve the problem in that car . . . I never did find any damaged or broken parts, just a sloppy adjustment. Gar if the shimmy occurs at low car speeds I would investigate the linkage, especially any joint that has a spring tension adjustment. dp

Posted on: 2022/7/7 13:38

|

|||

|

||||

007A.JPG (311.10 KB)

007A.JPG (311.10 KB)