|

Re: Ultramatic Parts Question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Why didn't you have it tested a little more thoroughly?

Posted on: 2010/11/9 23:58

|

|||

|

||||

|

Re: Positive Ground

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't recall ever seeing any kind of sticker. Positive ground was the norm for other cars besides Packard. Most stations or repair shops just knew back then or had a chart to look at.

Unless the car has an unprotected solid state replacement component installed somewhere, there will be no damage done if it is hooked up backward. So many have been done accidentally or on purpose over the years and owners never knew anything was wrong. Indeed, many of them have come to light after the current owner has been on the forum asking what was correct having just discovered their car was "different" than what the manual said.

Posted on: 2010/11/9 20:45

|

|||

|

||||

|

Re: Engine Bay detailing on a '56 dual carb car

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Removed capacitor so you could see the bend. Mine also has slotted screws on heater but lots of others like ones holding the metal cable clips for wire loom on firewall and the relays are philips. My car had a do over about 15 yrs ago. I know the bracket is original but don't remember which screws were changed or just re-plated originals. The components and screws were dirty, some rusty so the screws and everything not obviously painted went down for zinc plating. I was not too fussy with details such as getting screws back in the same hole then.

Posted on: 2010/11/9 18:29

|

|||

|

||||

|

Re: Engine Bay detailing on a '56 dual carb car

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Here are the best I can come up with without taking it off which I was going to do but arm is just not co-operating today. I can't see all of your bracket but it looks like it may be the correct one--coil is just slid in further. One thing I did notice is more philips head screws used on other things. Look at the rest of your car. If you see a lot of philips head, then this may in fact be the correct screw and that is what you need to find. That picture out of service manual with fuzzed center does sort of look like there is an indication it might be philips. That is one the radio noise suppression condensers.

Posted on: 2010/11/9 15:51

|

|||

|

||||

|

Re: Locked Rear end

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

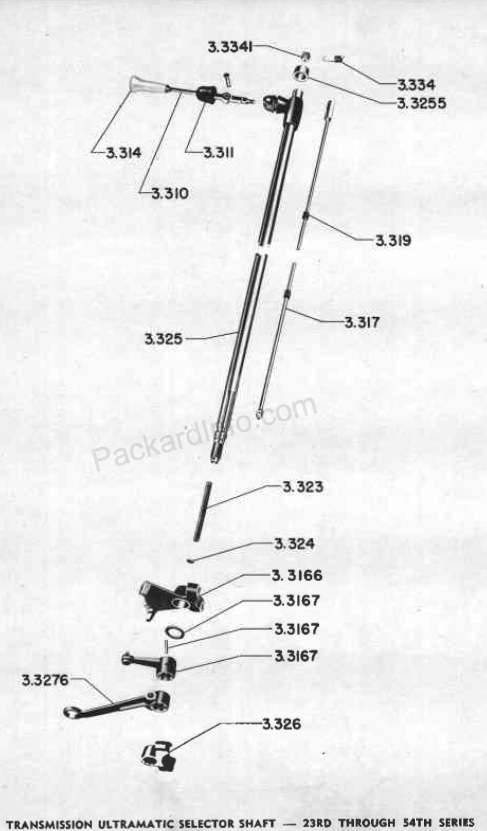

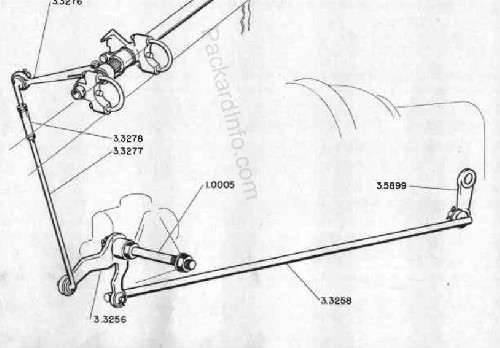

There is nothing in trans short of damage that would prevent linkage from moving. Even the park pawl is spring loaded and while it may stick, the rest of linkage should move. I would look at the base of steering column. When you pull the lever back, the arm at bottom that the linkage connects to should move forward slightly to clear a slight locking detent spot in the curved or triangle shaped sector. If it does that, then look at the linkage going to trans. There are a couple of spots it could be binding or something may have been bent.

EDIT: It is highly unlikely, and I don't recall hearing of it but I suppose it is possible after all that sitting that the manual valve could have gotten stuck in trans. That would prevent the linkage from moving. Would have taken some unusual circumstances to do so because the fluid should have prevented any thing like that from happening. If all else fails, then you may have to disconnect the driveshaft so you can move the car until you can work on it..

Posted on: 2010/11/8 22:13

|

|||

|

||||

|

Re: Locked Rear end

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

There is no interlock, other than pulling back on lever slightly before moving. If it does that and the linkage moves you should feel the detents in trans. If you do, and still is locked possibly the park pawl has stuck. If nothing moves then look at base of steering column and verify everything is hooked up and pulling lever back moves the mechanism at bottom. Is the trans stuck in park or have the brakes locked to wheels?

Posted on: 2010/11/8 21:47

|

|||

|

||||

|

Re: Pinion seal torque spec

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I'll ask tonite's dumb question. As I see it a single nut on the universal flange controls all. You tighten that nut until the crush sleeve starts to go and then tighten more until you get the in/lb turn spec whatever the nut torque happens to be and stop-- is that correct?

The 47 manual says when replacing seal to carefully mark the nut, count the turns to remove and then after seal is replaced, put nut back exactly as before and nothing will be changed. Also gives a turn spec but no torque. 51 manual gives a turn spec but also a torque spec of 300-325 ft lbs for the pinion flange nut. No mention of counting the turns but just gives the turn spec upon replacing. 55 manual gives a turn spec but no torque spec and same instructions. Guess the question is the 51 spec. Is that nut torque amount correct or do you really care what the torque is as long as the turn amount is correct. Apparently I am missing something in the picture because it would seem that you could put things back and have the right turn spec but nut be too loose. All very confusing for my feeble brain cell.

Posted on: 2010/11/8 19:11

|

|||

|

||||

|

Re: ENGINE: 327 1948

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

A bone of contention on color in 48 green vs gray. Particularly the senior 356. Believe most have settled on gray.

Kanter has the paint--use the link I gave you on the other thread. I think most use Bill Hirsch's paint.http://www.hirschauto.com/

Posted on: 2010/11/8 16:35

|

|||

|

||||

|

Re: Upholstery options

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

General catalog. Browse the online catalog then do a search for upholstery. They are custom made with modern fabric.

http://www.kanter.com/ Packard specific parts pages http://www.kanter.com/packard/

Posted on: 2010/11/8 16:31

|

|||

|

||||

(22.99 KB)

(22.99 KB)