|

Re: 1955 Patrician Brakes

|

||||

|---|---|---|---|---|

|

Home away from home

|

Phil_78: any chance you have and could add the part number for the Jeep shoes to the Parts X-Ref page?

packardinfo.com/xoops/html/modules/parts/index.php?cat=7&catname=BRAKES thanks

Posted on: 2021/9/17 14:01

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Removing Ultramatic Governors - Special Tool?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi, I thought I'd share an update.

I took the 3 control valve bodies apart, cleaned and reinstalled. I did not touch the throttle pressure screw. No apparent difference. Spent a lot of time trying to get the throttle linkage properly adjusted. The lever at the transmission has been there a while and the tightening around the gear points on the shaft from the transmission created distinct grooves where the lever attaches. The result is that I can't just move the lever a little, I can only rotate the lever to the next "worn in detent". This means the lever is either a tad too far counter clockwise (rearward) or too clockwise. This puts my adjustment point on the carb linkage to the very front of the linkage threaded shaft or so far aft that it won't work. I left it at the full CCW position since if it is just rotated off the stop the linkage can be assembled at the forwardmost travel near the carb. Based on other posts by Ross, this seems to be about right. When I drive: 'D seems to be fine. D': even with light pedal pressure it usually shifts L-H around 35-40 mph with a very pronounced (heard and felt) clunk. Then very soon after that a subtle 'shift' to what must be Direct Drive as acceleration is then smooth, solid and increased (consistent with Howard's write ups on how it is supposed to work). I was able to hook up a single pressure gauge to the transmission and separately measured pressures for the Front Pump, High Range Clutch, and Governor tests as per the "Pressure Test Forms, 55th Series" listed in the SM. The front pump pressures are low as compared to expected values and the governor pressures don't make sense to me.. ANY suggestions would be super helpful as to what to do next, what can be adjusted etc. (S/B = “Should be” from 55 Series Ultramatic Pressure Test Forms) Front Pump Pressure (1) @ ~400rpm (Idle) (Should be: 80-110psi) P 22 psi N 75-80 ‘D 60 D’ 65-70 L 65-70 R 65-70 ‘D 10-15mph: 180-200, (S/B 150-170) D’ Full throttle after shift to H: 120 (S/B: 80-100) High Range Clutch (2) (S/B <10psi above Pump Pressure above) ‘D @400rpm: 40psi (P.P. 60 from above) ‘D 10-15mph: 95psi(P.P. 180-200 from above) D’ @400 rpm: 0 (S/B 0) D’ @ 20mph: 0 (in Low gear, didn’t shift yet) Governor (7) D’ 13mph 20-25 (S/B 15-18) 28mph 30-50 (S/B 35-40) 56mph 20-25 (S/B 62-69) NOTE: Thanks BigKev for helping me format this properly.

Posted on: 2021/9/11 20:57

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Gear selection window

|

||||

|---|---|---|---|---|

|

Home away from home

|

First off, I am sorry to resurrect a 12 year old thread, but it had all the relevant info in it already so I thought that would make this easier.

In short, the base of the main 'tab' piece that fits into the steering column slot is broken so the pointer wont stay in one spot. It is part 3.308896 shown in post #23. You can see how that is fractured in this picture and that I have the 'old style' pointer clamp replaced by a new part # listed in post #8. So my question: does anyone have the main tab piece or ideally an assembly with the updated clamp the would be willing to part with? thx Bob

Posted on: 2021/8/6 0:06

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Removing Ultramatic Governors - Special Tool?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Partial Update:

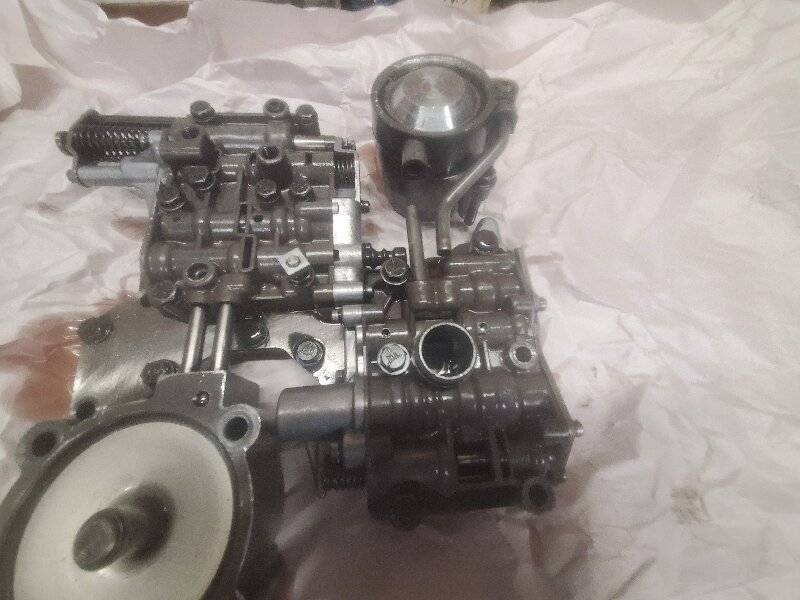

I removed, cleaned and reinstalled both governors. The low speed governor counter flyweight was intact. They were easy to get to with a socket extension and allen wrench socket. Even easier since I removed the control assembly. I did notice that the part on the manual valve shaft that pushes the parking pawl into place into it's gear was damaged and therefore won't rotate with the shaft. This would explain why shifter in Park position doesn't prevent the car from rolling. I think I will just leave it as is for now as this can be dealt with by using hand brake and is what some regulars here recommend anyway to avoid the 'stuck in park' situation. Looking at the Low speed brake unit, there is some shiny metal indicating some dynamic wear on it. Not sure how that happens, as I don't know what could be touching that. Since the low and reverse brakes are now out, should I bother to take apart and clean them?? I was surprised that the low one just slides off the tubes with little friction. The reverse one seems to be tighter on the connecting tubes. I plan on taking apart the three valve bodies and cleaning them out since I can. More to come. Attach file:  parking pawl lever on shaft.jpg (89.91 KB) parking pawl lever on shaft.jpg (89.91 KB)  low brake.jpg (140.09 KB) low brake.jpg (140.09 KB)  tranny control assembly.jpg (135.57 KB) tranny control assembly.jpg (135.57 KB)

Posted on: 2021/8/3 0:15

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Removing Ultramatic Governors - Special Tool?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thank you Howard and Ross, That gives me confidence to pull the pan this week to take a look see.

Ross, I am light in my knowledge of transmissions, but I will look for those items as possible causes. The detents are fairly vague to me, and Park is just like neutral in that the car will roll if the hand brake isnt engaged. I do have a set of gauges that i can probably hook up as in the SM, too. Thank you both again, Bob

Posted on: 2021/7/28 20:40

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Removing Ultramatic Governors - Special Tool?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Gents,

My ultramatic shifts 'hard' (Low to High) when driving in Drive-Right. It shifts >40 mph with a pronounced 'clunk' (and aided if I back off the accelerator when it sounds like it should have shifted already) I've checked the linkages a few times and all seem correct so I was thinking of removing and cleaning the governors. I haven't done anything w/ the tranny except change the Type F fluid (it still looks nice and red)and adjust the band bolt as per the SM. The SM (on page 54) references a 'special governor wrench PK-24.' So before I drop the pan I was wondering how special that tool really is or if I would be able to remove the governors with standard tools? thanks, Bob

Posted on: 2021/7/28 19:49

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Compensator Motor lubrication

|

||||

|---|---|---|---|---|

|

Home away from home

|

Updating in case others are rebuilding their compensator motor. Following Howard's input that this motor was a reconfigured generator, that helped me be more precise in my Googling. I found this link which really helped me. The backplate isn't exactly like our motors, but the rest looks the same. I didn't replace the bushing so didnt have to do any drilling, etc. I bought a new wick (John Deere Wick R11201, $1.61) from this siteshopgreendealer.com/John-Deere-Wick-R11201.html and it was the perfect thickness.

Hope this helps someone else, someday -Bob forums.aaca.org/topic/273106-generator-rear-bushing-question/

Posted on: 2021/3/3 21:54

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Compensator Motor lubrication

|

||||

|---|---|---|---|---|

|

Home away from home

|

thank you for the reply. Since the plate that covers the oil wick would be vertical when installed, making oil messy with no real reservoir in that orientation, I thought grease would make sense.

But since these motors don't spin as often as a generator, I was thinking they wouldn't get warm enough to melt grease so oil would make sense. The generator lube chart in the SM calls for drops of 20W oil (every 1,000 miles! Who does that?) but it has oil cups to drop the oil down... The wick on this T-L motor touches the armature shaft (vs oiling an oil-lite bushing) so I was thinking grease.. :) Maybe it really doesnt matter as long as there is oil or light grease there vs nothing at all. The stuff I pulled out felt like grease vs congealed oil but never can be sure..

Posted on: 2021/2/10 22:49

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Compensator Motor lubrication

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Gang,

I'm in the process of rebuilding and cleaning up the T-L system in my '55. This includes cleaning up and regreasing the compensator & motor. I took the motor off and apart and was wondering about whether to use oil or grease for the oiling wick at the base of the motor. With a wick, I would normally assume an oil, but it looks like there was grease in there so asking here. The lube charts in the manual don't address this point. I'm using the StaLube SL 3303 for the Compensator gearbox and can use that for the motor shaft wick, too. But worried it may be a tad too thick to migrate down the wick to the armature shaft in the bushing. thanks, Bob

Posted on: 2021/2/7 23:31

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||