|

Re: Rivets for Hood Louvers 1932 901

|

||||

|---|---|---|---|---|

|

Home away from home

|

You can check out this site

rivetsonline.com/rivets They have quite a selection. HAPPY THANKSGIVING to all

Posted on: 2024/11/28 13:47

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: Drifting air fuel adjustment

|

||||

|---|---|---|---|---|

|

Home away from home

|

Been a while since I checked in.

We took a trip to Austraila, New Zeland, and Fiji in Sep. Oct. so I have not driven the car much. I did replace the spring with a panel grommet that was about the same heigth as the spring in mid August. I was busy finishing up projects around here so I did not drive the 37 much. Now that I am back I have had a couple of chances between the rain storms to drive into town. I'm glad to report that the carburator is staying in adjustment. I got in to back it out of the garage late last week , set the choke with 1 full depression of the pedal and hit the button, the engine started to roll and before 1 full revolution it fired right up and came to a good fast idel with very little black spitting from the tailpipe. I think the gromet also helped seal up the idel screw threads improving the air fuel ratio .

Posted on: 2024/11/15 1:12

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: Drifting air fuel adjustment

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks to all

I see the flex opening the screw, missed that one 😊 Stromberg BXOV 2 I think ? ( or 3) This is what was installed by last owner, I have the original GC that needs rebuilt. This evening I installed a rubber grommet and a small O ring in place of the spring. I like the idea of a star washer, see how the rubber works,

Posted on: 2024/7/11 20:59

|

|||

|

Larry Reber

|

||||

|

||||

|

Drifting air fuel adjustment

|

||||

|---|---|---|---|---|

|

Home away from home

|

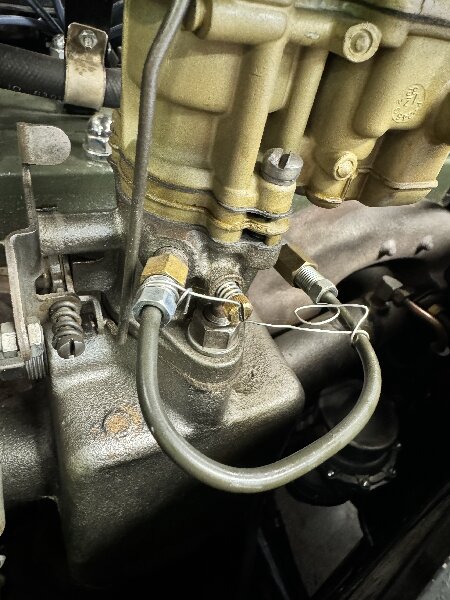

OK, so here’s the story.

37 Packard 115 C. Stock carburetor. I have a constant issue with the air fuel idle mixture screw drifting. This causes over fuel condition, rough running, etc. In the picture was my fix. Does anyone have other suggestions on how to keep the needle valve screw from adjusting out. This usually happens after I’ve driven the car and parked it and let it cool down. The car started right up at the garage. Ran great until I got about 2 miles from our dinner stop.. When I parked I turned the screw about an eighth of a turn, maybe like a 16th into the lean and the car idle right out. It ran ok back to the house and then t turned about 1/8 turn lean and it smoothed out , better than the parking lot adjustment. Thanks

Posted on: 2024/7/11 13:46

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: '37 6 Crankcase Breather tube?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Also check David MOE Packard Seattle

Posted on: 2024/4/15 12:06

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Home away from home

|

Got hung up with stuffffffff. Glad there was anoher camera ready member..

Posted on: 2024/2/5 23:36

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'll get a couple of pctures later this morning.

Posted on: 2024/2/2 12:43

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: Upholstery Refresh

|

||||

|---|---|---|---|---|

|

Home away from home

|

Not sure if you found a shipper but I've heard FASTENALL does a store to store transfer service.

One thing is I believe you need to pick up your items ASAP.

Posted on: 2023/12/30 13:53

|

|||

|

Larry Reber

|

||||

|

||||

|

Re: Upholstery Refresh

|

||||

|---|---|---|---|---|

|

Home away from home

|

First, HAPY NEW YEAR to all !

My friend and I did the interior on my 37 115c and I did a series of posts about the project. My life experiences had NO upholstery in it and Linda was an at home seamstress with no upholstery experience. We decided that it was just pieces stitched together and if we could disassemble it and measure it than we could duplicate it. In the postings I tried to cover the high points of the issues found. Topic: "1937 115c touring, Upholstery" Please check it out as a little pre new year relaxation. Larry

Posted on: 2023/12/30 11:16

|

|||

|

Larry Reber

|

||||

|

||||

IMG_2544.jpeg (963.15 KB)

IMG_2544.jpeg (963.15 KB)