|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I have confirmed that I have a dead battery. I was able to jump start it with my wife's car. I let it run for a few minutes and then turn on the under dash I/O switch to active the leveling system; the 30 amp fuse blew after a few clicks of the solenoid, and then the car stopped running. I did hear the electric motor run before the fuse blew and before the car stopped running. I guess the next step is a new battery.

Thank you very, very much all of your help. I really appreciate it!

Posted on: 2013/4/24 22:22

|

|||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Home away from home

|

When I had to take the motor off the TL gearbox, the armature stayed in place. I then spun it to move the bars the way I needed it to go. It went faster than a screwdriver, but not as fast as putting a screwdriver bit in a drill.

If your TL did rotate the wrong way, you will need to look at the short bars to see if they are bent. You might need to look at the gear box for damage. The limit switches need to be checked too.

Posted on: 2013/4/24 22:54

|

|||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

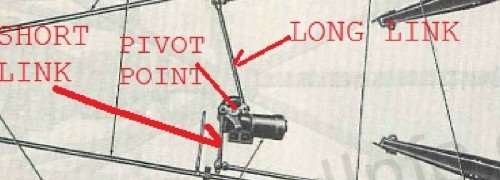

I was able to squeeze under the car tonight and look at the short and long link bars and see where there are in relation to the pivot point. Bad news is they don't look like the attached diagram. It looks like the short extending knob of the pivot point has moved too far towards the front of the car; moreover, it looks like it has bent the short link/bar.

I'll try and lift the back of the car on some jack stands and get a picture of it. I'll try and lift the back of the car on some jack stands and get a picture of it.

Posted on: 2013/4/24 23:36

|

|||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Here's a late update to this problem. Long story short... I got it fixed. I had to rebuilt the compensator. All is working now.

Posted on: 2015/8/2 15:06

|

|||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Glad everything is working now. You said the compensator had to be rebuilt. Did the splines shear off the last output or was it something else.

With the different design limit switches for 56, most problems with the switches not stopping the system were eliminated but a shorted or stuck solenoid can't be ruled out. Bars being bent on 56s most likely means the limit switches were bypassed with some kind of mickey moused manual switch setup or the motor was directly powered and no one was watching what was happening. Hopefully none of that will come back to haunt the car and the fuse will blow before any damage is done.

Posted on: 2015/8/2 15:57

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Sorry for the late reply. I've been enjoying my summer driving my Clipper around my neighborhood, and I went to my first car show.

The torsion bars were not bent. The mechanic that rebuilt the compensator did not say the splines seared off; he basically cleaned it up. The leveling system works, but not consistently at 7 to 9 seconds. It may take 2 to 15 mins for the car to level when passenger load up in the back seat, or when i load up the trunk. Any suggestions as what would be causing the leveling system to be inconsistent?

Posted on: 2015/9/19 17:14

|

|||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

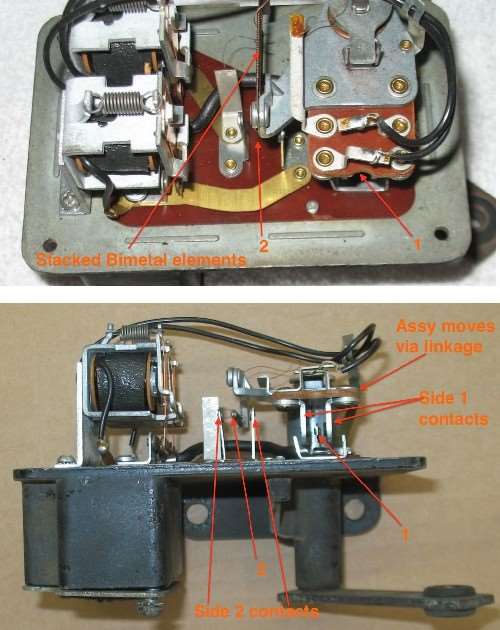

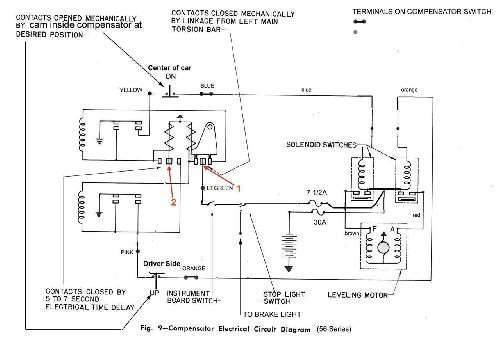

Assuming all the other connections are clean and tight and limit switches are good so no intermittent signals between the control sw and solenoids and the mechanical link between the main bar and compensator switch is solid and not slipping on the bar, the only thing left that would vary the operation is the compensator switch.

Here are a couple of photos of the original bimetal type switch and a complete 56 schematic showing the internal contacts. If you have a solid state replacement switch then that is a completely different operation in bringing in the relays. On the original switch, when the car is out of level it moves the internal assy via the linkage. That assy is spring loaded so only rotates slightly with springs taking the extra force. The slight rotation is enough to ensure the center contact at 1 touches one of its two side contacts. Depending on which contact is made that starts heating one of two heating elements wrapped around a U shaped bimetal strip. The elements are separate and on different legs of the U one above the other. Heating one element causes it to bend the bimetal one direction and if the other contact is made the other element heats to bend the opposite direction. The bending accounts for the approx 6 to 7 seconds delay and when it has bent far enough the end of the bimetal at 2 touches one of its side contacts and brings in a relay to energize a solenoid and start the motor. As the car levels, the linkage also moves the rotating assy in the control switch. Because of the spring loading the car can move a considerable amount but when level is near the springs are no longer taking the force so the assy starts to rotate again. When level is reached the center contact at 1 breaks the connection to the side contact and relay drops out the solenoid stopping the motor. If it is taking a long time it could be the ground to the control switch is poor, the voltage on the light green wire is low or one of the contacts at 1 inside the switch is oxidized so the heaters are not consistently getting enough voltage to heat the element. If that mechanical part is OK it is possible the element is not making a good solid connection at 2 to bring in a relay. If you have a solid state reworked switch then that is a completely different operation and I would surmise something has happened to the electronics.

Posted on: 2015/9/19 18:32

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Leveling Problem on '56 Clipper

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

The switch on my car is original. Thank you for the detailed explanation. The photographs and diagram help. I'll update this post when I identify the fix. Thanks again!

Posted on: 2015/9/19 20:11

|

|||

|

||||

(39.11 KB)

(39.11 KB)